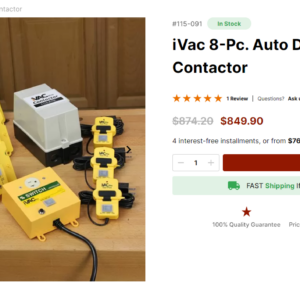

Curious about Ivac blast gate system or like

I’ve always seen, wanted, and wondered about these automatic blast gates.

https://infinitytools.com/products/ivac-8-pc-auto-dust-collection-w-contactor?gad_source=1&gclid=CjwKCAjwnK60BhA9EiwAmpHZwyl5O7r4VxYe2Ieq_dbPudBJ_bIhqDJFvgsAPqgI9E2PoEOqEC9CbRoC-v8QAvD_BwE

I know they seem like, “How about don’t be lazy,” lol, which I agree with, honestly.

My argument is my shop is extremely small, and no matter how I figure out my dust collection system, it is always pretty inconvenient.

I’ve got a quarter of my spine bolted together along with various other body parts, so extra movements, bending over, ect aren’t ideal for me.

I always had this pipe dream of having the ability to change gate configuration right from where I’m at with no extra movements.

These Ivac ones seem to be the only ones easily found online.

Does anyone have experience with these, or is there a similar brand?

Has anyone designed their own system? I have the electrical knowledge and skill to do that, but I don’t like the idea of the required time investment in designing and sourcing parts, although I am getting closer and closer to doing it.

Other thoughts or ideas on this, in general, would be appreciated, too.

Replies

I got mine years ago and absolutely love that system. It's always worked flawlesly. It was very easy to set up.

I’ve had them in use since 2017. I have two on my table saw, one for an overhead Excalibur blade guard / dust extractor, and the other to the cabinet base. These are the ones that are programmed as open by default. Two others are on the thickness planer and jointer. I use manual gates for, floor vac, bandsaw, mitre, router etc. as I move them around to various ports and use their remote to turn on the DC. Works great for my work method. Previously I had all manual and might neglect to open or close, especially at the TS for a quick cut.

Company is based in Ottawa Ontario, good customer service, having had to replace a blast gate. I also use their led drum fill indicator on my cyclone, which works quite well.

Thanks for the feedback guys.

What happened to the blast gate you had to replace?

How long till it failed?

It was a bit strange, wasn’t a fail per se. As I recall there was a buzz under suction and on occasion it would get out of sync between open and closed. It was in the first year that I had the issue. They gave me a replacement right away and wanted the old one to test and determine what went wrong.

I had purchased directly from the company, not sure, but would assume a distributor such as Lee Valley would have a similar exchange / refund warranty.

Glad to hear they took care of it. sounds like a situation they could have been pains in the ass about if they wanted.

its a great system, i have the 8 gate version, works great. motor controller a little clugy to wire up (im using with oneida super cell), and has to be reset any time there is power surge/break, but otherwise great. per pic below, i use one of the controllers as a switch for small vac hose (palm sanders, etc), and it works great - turns on vac, opens gate, closes all others, etc. they sell separate switches but not sure whey would use vs the controller.

Thanks.

You could put the controller on a UPS to solve the power blip issues.

I just installed 2 iVac blast gates and put sensors on the power cords for 3 machines. The previous manual gates in my shop were in difficult-to-reach spots so the automatic gates are a huge plus. My dust collector is 1.5HP/115v. Since I already had a remote (the Long Ranger III) for it, I opted not to get the iVac switch that turns on the dust collector. Please note that for 1.5HP (115 volt) dust collector, I would have had to wire in the additional contactor.

Thanks. it's looking like I'm gonna go ahead and buy the system.

More people than I thought have chimed in and said good things. I figured this would be a zero-reply post or people making fun of it and me for wanting it.

Kinda excited.

I've been trying to build my own version for a while. Honestly is is a pretty difficult project. Building gates, that open and close electronically and keep working is more difficult than it seems it should be. I'm on about the 4th revision right now...

I have a working dust collector control circuit and functional software but no automated tool detection yet.

When I'm done I'll probably be a little ahead money wise but I'm also looking at like 12 gates in my shop.

If you are not excited about a project to build a system, just by the i-vac.

I applaud those who have the resources to buy and install this kind of shop assistant. These things were not available 20 years ago when I set up my shop, so I devised my own system. Here is a link to the page on my website:http://www.jimsworkshop.net/Shop_Tour/#jimsworkshopweb004003.jpg. Basically, I open the blast gat attached to the piece of equipment I'm going to operate (chop saw, planer, router table, etc) and the dust collector starts. Close the gate when done, DC turns off. Cost was minimal: switch on each gate, 115v to 12v transformer, 22 gage speaker wire, a 12v relay that can switch 220v (the most expensive item), and a handmade box to house it. There is nothing that can break or wear out, except maybe a blast gate, but that can happen even without a Auto-on system.