I am struggling to find a reasonable solution to machine mortises in a rail and stile construction glass front door on a cabinet. I’m working on the “Better Built Cabinet” by Steve Latta (issue #284) and I do not want to use cope and stick bits.

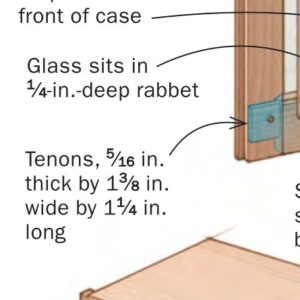

The cabinet plans call for drawbore mortise and tenon construction that is 1 & 1/4” deep. The rails and stiles would have a 1/4 inch round with a 1/16” reveal machined into the front and dado in the back for the glass. The mahogany I have is just shy of ¾” thick which leads me to use a 1/4 inch mortise.

I’ve used my plunge router with a bushing and MDF pattern successfully on other projects but in this case the 1/4 inch bit only cuts 1” deep. The 1/4 round machined into the face means I can stretch to get a 3/4 inch deep mortise. I guess this would still be stronger than a basic cope and stick structure but I want to find out how to build this to plan. I have some experience with chisel work but a 1/4 inch wide mortise that is that deep seems problematic for me. Is a mortising machine my best alternative?

Thanks Kevin

Replies

Kevin,

A good quality (i.e. one that actually works) mortising machine would be expensive. So would be various dedicated router-guidance machines that can operate like a mortising machine - Router Boss, Woodrat and similar. Mind, the latter are far more versatile than a mortising machine, which does only one thing.....

But if you already have the skill & knowledge to mortise using a simpler guide for a router, why not just get a long upcut spiral mortising bit?

Personally I would use a Woodrat to machine-cut mortises (and the tenons) in face frame or door parts. Slim but deep mortises such as yours are easily made using a long upcut spiral HSS bit that will plunge up to 2".

I don't know where you'd buy such a bit in the USA but surely such a thing will be available from one of the many bit manufacturers?

It would be possible to use such a bit freehand if the workpiece is strapped down so that the router can ride along its edge; and the router is perfectly guided.

With frame parts, it would be best to give the stiles large "horns" so that the mortise is cut well inboard from the end of the piece. Personally I've cut mortises this way using a router with two fences (one each side of the bit) on longer-than-standard arms, to keep the router centred on the stile being mortised.

I also put temporary outriders on the (long) fence arms each side, to stop any sideways tipping of the router. The deeper the mortise, the more precarious a freehand plunge-cut with a router will become. You can't allow any tipping as the end of the long bit will snatch deep down in the partly-completed mortise, with unpleasant results for all.

It's a lot easier with a Woodrat. :-)

Lataxe

A dedicated mortiser is probably the best solution, but it certainly isn't the only one.

I'm not sure what your mdf template for mortifying looks like, but it sounds like it is preventing you from going deeper. Tage Frid in one of his books has a router mortifying jig that allows the full length of your bit into the mortise. I used that jig for many years and found it very useful.

A mortising machine would knock this out quickly. If you do m&t often you'll be very happy to have one.

You could also go as deep as you router setup allows and finish up with chisel work. A lock mortise chisel will be a big help down deep. If you decide on the handwork leave yourself an extra inch of stock outboard of the mortise to support the levering action.

And you could go old school and use a mortise chisel. Go in from both sides to eliminate tea rout.

Hi Kevin,

My preferred way would be to chop it by hand, but I'm crazy and have been for a long time!

Can you drill the mortice to depth with overlapping plunges using a Forstner bit, rout as deep as your bits/jigs allow, and then pare the remaining scallops at the bottom of the mortise with a chisel? The drill gets you your depth, the router cuts the majority of the mortise cleanly, and the chisel work will clean the bottoms.

3/4" would be sufficient for this size door but if you want to go deeper a high speed steel end mill should work and are available in longer lengths.

https://www.mcmaster.com/high-speed-steel-end-mills/high-speed-steel-square-end-mills-for-aluminum-brass-and-bronze/

Regarding drawboring, in my experience, it is waste of time. Pull the assembly up tight with clamps, drill and peg it, remove the clamps and set it aside to dry.

Thank you for all the comments this was very helpful. Being a beginning/intermediate woodworker I'm not ready for something like the woodrat but it looks like a very interesting jig. I had cut the stiles with an extra 1/8" thick which would leave a 1/4" floor to clean up drill waste from getting to depth I was concerned I might blow out the back...this would be my second careful option. I couldn't find long enough router bits so thanks for the link to the end mill bits; however unless I have a better jig I'm now a bit leery about having that much spinning steel in my router. The best option for my setup would probably have been through tenons but I've already milled the rails to length. However I found a Fisch sp? mortising machine I can borrow - it's an inexpensive benchtop that's hardly been used but thought I would try to clean/tune it up and see if I can get some good results with it. If it isn't acceptable I'll drill to depth and use some gentle chisel work. Thanks Again

One more thought - I was concerned about drawbording the 1/4" mahogany tenon as perhaps the end grain would split out with too much force. I've had good luck with larger maple pieces, but I think with this one I'll just pin in place. Thanks again - Kevin

Your best alternative is with a chisel and hammer. Machines cause more problems than they are worth. But that is just me. I like working wood with hand tools, not machining it.

I'm with you on this one.

For the small number of mortises involved, and the relatively shallow depth, it's probably almost as fast to do by hand as any other way.

A decent set of mortise chisels will cost way less than any machine and are REALLY easy to use. I mean, so easy that once you try, you'll wonder why you bothered with the machine idea at all.

I would also add that the extra 1/4 inch and draw boring will add nothing to the strength of the cabinet unless it is stuck together with boiled gummy bears.

" ... boiled gummy bears ... "? Sounds like someone makes tasty projects.

Drill it out using a dowel jig (for vertical alignment), clean up scallops with a wide bench chisel. Don't mark your tenons until the mortise is done. Set your mortise gauge to the interior width of the mortise to mark the tenons with the pins just barely making contact. Saw the tenon splitting the lines. The tenon should fit with the gauge marks still barely showing.

You could use an old Stanley jig and a brace to do this, but some auger bits are sized a 64th over nominal and will not fit the guide bushings in the Stanley. I've found that Stanley Handyman auger bits will fit the Stanley 59 jig perfectly. Your other alternative would be a new dowel jig and there are literally dozens made.

Make a couple of test joints first!

This forum post is now archived. Commenting has been disabled