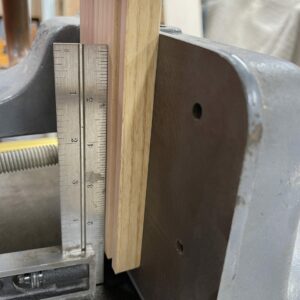

I recently found an old Delta 1172 Tenoning Jig and was putting it through the paces. I noticed that the machined surface that the workpiece is held against is not 90 degrees to my Unisaw (see photo). It is registering as 90.2 on the Wixey, with a double square telling me the same thing. On a test run it translates into a tenon that is wider at the base than the end. It’s there anywhere on the jig I can add a shim to correct this? Any help is appreciated.

Replies

I do not have that particular jig and the photos don't show much so...

First you might try stripping the whole thing down to clean out old junk while looking for wear on surfaces or hardware. If all looks right & tight and it doesn't rock on your sawtable I'd start with a couple of layers of tape under the baseplate at the outside edge. If it solves the angle issue you can swap it for something more durable like UHMW tape before you go looking for a machinist.

Since you have the wixey cube, have you tried to match your blade angle to the jig? Not ideal, but maybe managable.

If cleaning it up doesn't work, you could also attach an auxiliary pad to the vertical face and shim it plumb.

This is off subject a bit, but why not ditch the jig altogether? Just use your table saw fence, it is simple, accurate and quick.

Those old cast iron tenoning jigs are lovely but quite unnecessary.

From the brief research I could do, it does not appear that the face on this model is adjustable. However, there are 4 screw holes on the face for the purpose of attachments. You can simply build a new face utilizing these four screw holes and shim the face as needed to get it perfectly square.

This forum post is now archived. Commenting has been disabled