Desk/Piano Tray – Sheet Metal Thickness/Necessity

Hey all! I’m building a custom desk with piano tray and am a bit stuck on a couple things. I recently stumbled across this site and I did some searches but couldn’t find much on my need so hopeful the amazing community can help out?

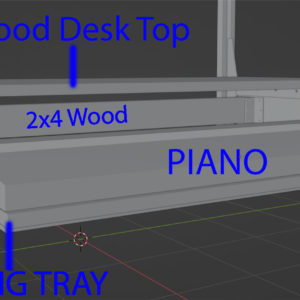

I’m trying to find information on the necessity and thickness of using sheet metal vs. wood in my project. I’ve attached an image which should show what I’m looking to accomplish. Essentially it’s a regular desk, with a sliding digital piano tray, that is attached to an elevator system in the garage of my RV. Since the piano will be taking some downward force I’ve chosen heavy duty sliders, but I also want to make sure that there the other pieces are heavy duty. I figured that I could use a wood top – with threaded inserts and bolts/nuts/washers to bolt it direct to the metal elevator.

My thought was for the side reinforcement pieces it might be best to use sheet metal but am unsure of the thickness I would need to guarantee that the project is heavy duty and can take the use of the piano as well as movement of the RV. Do I need sheet metal here or do you think that threaded inserts into a hardwood would be strong enough? If I do need sheet metal – any idea on the thickness I’d need? I am unsure of the strength capacity of metal comparatively and am finding that thicker metals are obviously much heavier. The elevator is able to support upwards of 600-800 pounds of downward force but I want to make sure the structure I am developing is heavy duty.

Apologies for the long post but I’m stuck and could use some expertise. Genuinely appreciate any help or advice any of you can provide. Thanks again!

Replies

It looks to me like a plywood structure hanging on the elevator brackets would do the job. Since it's in an RV you might consider slides with lock-in / lock-out functionality.

To support your drawer hardware your going to need more than sheet metal,your going to need something like boiler plate. Something that you can tap to accept a tread. Personally I would consider something like 1/4" or better aluminum because not being a machine shop it's much easier for me to work. I could get it done with stuff I have.

Thanks for the responses! Yes I'm definitely looking at slides that the lock-in / lock-out functionality - I think that will make a big difference to be able to lock it in place when it's not moving just to keep things sturdy.

The boiler plate thought definitely helped point me in the right direction. I'm now looking at 1/4" x 12" x 24" aluminum plates which I think should fit my need. Any thoughts of aluminum vs. steel? I'm finding that I can find both at similar prices but wondering if the added weight of steel will be worth the extra durability gained.

Considering durability as a factor implies a source of wear & tear... from what?

The forces I'm considering are the downward forces from using the piano daily as well as any shifting that might happen when driving. I'm not slamming the piano perse but I assume because of the angle of the tray that there will still be some wear due to the angle and weight combined with normal force from play. Most piano stands have legs/supports and mine will be hanging so I assume that there will be some wear to the holes where the bolts will go. I'm thinking of doing threaded inserts and bolts with washers to distribute the wear but still wanting to make sure that I don't have any issues. After a few thousand miles of driving I've seen wear to other metals even from just bungee cords rubbing back and forth. Granted this will be quite a bit thicker than other metals I've seen that have wear, I still don't want to take any chances if I can instead plan appropriately.

Hope that helps - definitely appreciate any additional perspective!

I think you could use metal or wood without strength issues. I would favor wood, no surprise based on where we are. Properly joined wood construction will not vibrate loose with the RV milage and is just a warmer experience under the hand. Fixing drawer slides to a soft metal like aluminum is doable, but fussier than working with wood.

Send a link to the elevator hardware, I'd like to check it out.

Thanks again for the perspective. I'm going to take a look at some hard woods and compare them against aluminum. I definitely see how there are pros and cons to each scenario but glad to hear that both will likely work.

In terms of the elevator system - it's a happijac bed lift. https://www.ebay.com/itm/144535168743

Mine came pre-installed in the RV - there are two arms on the bottom that used to hold two couches that convert into a bed, and there is also a second set of rails that hold a bed that lifts up. I can lock the bed to the ceiling and bring the lower arms down. I removed the couches and the rails are still available so I'm going to be building my computer desk / piano tray on one side and then on the other side I'll have another desk that I'll have set up as my workbench.

I attached a gif that shows the bed/couch in a couple different positions. If the animation doesnt work you can see the original here: https://www.granddesignrv.com/sites/default/files/floorplan/Media%20browser/Garage-Happijac-mclass_3.gif

It's a little pricy if you buy it aftermarket compared to it being preinstalled but the thing is solid. I've been very happy with the system so far and imagine I'll be even happier once I have it modded with my desk & workbench.

This forum post is now archived. Commenting has been disabled