Hi there,

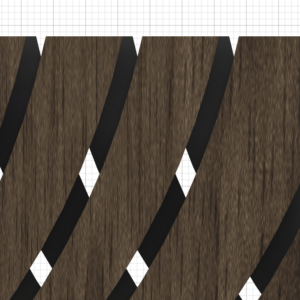

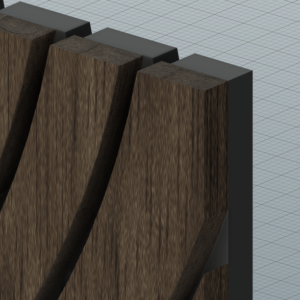

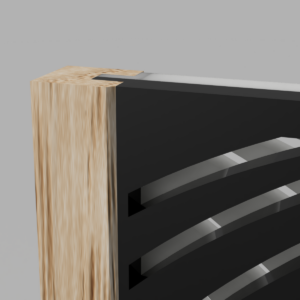

I want to make a door panel that will sit inside a frame and panel door like the one in the pictures.

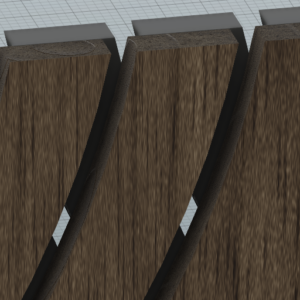

My plan is to glue two timber pieces (quartersawn) face to face, and cut through them on the CNC to create a lattice pattern.

I will glue a lipping on all four edges, and create a tongue on that lipping (instead of the panel), so you can’t see the groove when you look through the lattice.

Does this seem like a feasible idea? I’m cautious to make the panel too wide due to wood movement. Thanks

Replies

Hi agthomas

Not sure if I understand your design completely, but looking at your sketches, it seems you're building gaps between your curved slats, making for a truly beautiful design, but also providing space for wood expansion. I'm pretty sure that if you glue the front and back together, the glue will withstand wood movement since the grain is almost parallel. I wouldn't worry about making the panels too wide.

Good luck!

Glued together face to face the panel will behave like a solid plank of wood. Do the math on the species and your climate zone to get a feel for how much it will move. The size of the panel will matter a lot.

Gluing a rim to the top and bottom edges' end grain is a questionable thing to try. Stopping your cuts shy of the top/bottom and milling in the tongue would be more stable. Gluing to the sides is no issue.

The panel needs to be fully housed in the groove. Otherwise, when it expands it will push the frame apart and when it contacts it will expose a gap around the edge. The decorative grooves will not provide expansion/contraction gaps, the panel will act like solid wood.

I agree with Jake that the panel will behave like solid wood, so you will have to plan for wood movement, in particular across the width of the panel. As I see it, you have two options:

1) Glue tongues on the back of the panel, with the grain of the tongue pieces going the same direction as the panel grain (so at the ends, the tongues will have the grain going across them, rather than along them.) Before gluing them in place, mark and cut away the areas of the decorative grooves just to the end of the panel.

2) Make the lipping thick enough that you can make pieces with grain going across them for the panel ends that have enough strength to stay together until glued to the ends of the panel with epoxy. You will need to use a wood that doesn't split easily (which leaves out such woods as oak, hickory, ash, walnut.) When you glue up the end grain lipping, use long set epoxy, put some on both sides of the joint, let it soak in, apply more, and clamp them on. Leave the clamps on overnight.

When you make the tongues on the lipping, you want there to be a 1/8" reveal between the full thickness panel and each side of the door frame, and the tongue should leave a 1/8" gap inside the groove in the door frame. This allows for expansion of the panel unit if needed. After the door frame is glued around the panel, I center the panel so the reveal is even all around, then, on the back of the door, I shoot a short 23 gauge pin nail into the center of the top and bottom rails of the door frame that catches the tongue to keep the panel centered in the door opening. You can also drill and install a 1/8"dowel from the back instead of a pin nail.

This forum post is now archived. Commenting has been disabled