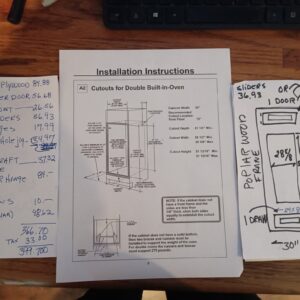

Hello All . I haven’t posted in years since I totally gutted and rebuilt my current home (2010 maybe?) So just getting back to rebuilding the original double oven cabinet with an updated version of the original.

Excited about getting a bit back into wood working . Anyhow, So thought I’d post some pic’s.

Some basic tools on hand router, assortment router bits ,coupe straight edges,squares,levels plus other misc. woodworking pieces.

I’ll be getting a hold of a couple specialty tools,Kreg or Milescraft pocket hole jig.

Rockler hinge jig for easy installation of european style compact hinges. unfortunately a a nice table or track saw isn’t in the budget.

For starters, for the majority of the build, I’ll be starting with a 4×8 sheet of veneered Burch plywood. First thought being, since I have no access to a track/table saw, hopefully having someone at HD do the first “cut to size” rip and cross cuts on 4×8 sheet panel. Thought about pulling out the old Skil 77 and straight edge , but I’ve actually found our local HD’s panel saw being pretty accurate.

Sorry for the long winded rant LOL, I have a few questions though .

Is cutting a dado in the side panels the more accepted/common method ?I’m debating whether to use my router to dado the side panels in addition to an additional plywood base on top of the first. ( 3/4″ base panels with additional cleats glue and exterior screws through the sides?)

The spec sheet calls for a 400 lb. rated base. Which would lead me to believe rather critical.

What do you think of either finger joints or dovetail joints ? I have seen more simple methods for drawer construction . ?

Seriously appreciate any experience , tips or advice.

Forgot to add : the first quote back in 2010: 1600.00. today: 1900!

Discussion Forum

Get It All!

UNLIMITED Membership is like taking a master class in woodworking for less than $10 a month.

Start Your Free TrialDiscussion Forum

Digital Plans Library

Member exclusive! – Plans for everyone – from beginners to experts – right at your fingertips.

Highlights

-

Shape Your Skills

when you sign up for our emails

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. -

Shop Talk Live Podcast

Shop Talk Live Podcast -

Our favorite articles and videos

Our favorite articles and videos -

E-Learning Courses from Fine Woodworking

-

-

Fine Woodworking New England Event

Fine Woodworking New England Event

Replies

when I built mine, I cheated. I had an existing spot for an oven and built the cabinet inside that, simply cutting side pieces then laying a shelf atop that - effectively dado joints, but full depth - it was the easiest way to do it and it worked well.

Couple of suggestions - if you can get accurate cuts then awesome, but you do have to triple check your measurements. I would make a track guide for the skil saw and use that as you may need to change things.

A router is a really good way to cut dadoes, but given you are using archaic measurements of weight, you may need to select your bit very carefully as most sheet material is metric dimensions - get the appropriate metric bit.

200Lbs is not much - easily managed on simple dado joints, especially as ovens have feet which mean that the weight is borne at the edges. No need for fancy joinery. Just use 18mm (3/4") for the base. If you really want super strong then you can design with your kick-board under the base so it supports it. Screw in from the sides.

Get the Kreg rip-cut and the Kreg pocket hole jig. The rip-cut makes it easy to cut down sheet goods. I have done about a hundred sheets of maple plywood with mine. And pocket holes are easy and strong. Get the jig set properly and use the right screws. You can glue the joints for insurance if you feel the need. Pocket hole the face frame too.