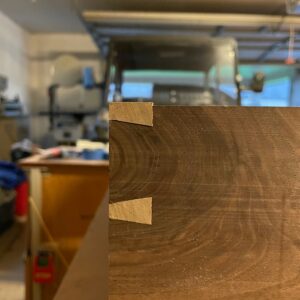

I used my leigh jig to route some dovetails for a long box. I checked that the ends were square, but I keep getting the issue where I am about 1/16″ up on one end all around. Basically the top and bottom of the box are not flat. I have attached some pics and a 3d image to further illustrate my issue. Note, if the top is proud 1/16″, the bottom of the same board is less 1/16″. I’m thinking I was not perfectly square even though my engineers squares said is…not sure what happened.

Currently the box is not glued up. Was thinking I could strike a line across the top and trim it off with my table saw (would have to make a jig to keep it square). Anyone have a fix for this or a way to conceal it somehow. I cannot remake it due to a deadline. Thanks!

Replies

Man! I know what you mean. That problem used to drive me crazy until I switched to a dovetail saw.

Sounds like it's pretty common then?

It absolutely is.

“[Deleted]”

How long is the box? If you can set the whole box on the top of your tablesaw would use the tablesaw as a reference and scribe a line around the box on one side.

Handplane to the line, or cut to the line using an l-fence and a guide board on the tablesaw ( https://www.finewoodworking.com/project-guides/shop-projects/the-incredible-l-fence )

Then, once you have one side straight, I would set my tablesaw fence and rip the wonky top off the box.

its 34" long. I'll look into the L fence. I was sort of thinking I could scribe the boards and trim them flat, then assemble and trim flush on the other end. Thanks for the info!

I have no idea why the jig is giving those results. But a few swipes with a plane will even things out.

Does this make the box is out of square, right?

The box is square, just has high spots in the corners, which means the ends were not perfectly square (though I though they were. I have similar (but to a lesser degree) on pieces that are about 2" wide. Could be the jig. It's used, but I checked the squareness of the fingers to the side adjustments and that is dead on. I can only assume my boards are a bit off and the problem is exacerbated on the long boards.

“[Deleted]”

Handplane one side until it sits square, take it to the tablesaw to get it close, then finish with a plane. Put it on a carrier so it will ride flat through the saw, plane off the proud pins last.

Thanks!

Those pictures and diagrams show relatively small uneven places. I agree with using planes and if parts are more uneven than shown, I use a flush cut saw followed by planes or chisels to even things out.

Thanks ecyor. It is about 1/16" or less. I'm def going to go home and stare at it for some time. Thanks for the feedback!

Knocking off high corners will, geometrically, make the box un-square. But 1/16 over 34 inches is negligible for woodworking. A few more plane swipes and your top will sit just fine. If it were me, I'd glue it up and make adjustments after.

Thanks for the info! V

John_C2, I was doing a bit of searching on this some more. What are your thoughts on glueing up the box, then adhering sand paper to a flat board and sanding it flat that way? Since it's not a lot of material and I don't want to make a mistake with a hand plane (have not mastered that quite yet).

I've never done it that way. You could, but it would be slow. You can use a power saner, but there is the possibility of munging it up.

Probably a stupid question, but wondering if you tried flipping the tail board over so that the outside of the tail board is now on the inside and current inside of the tail board is now on the outside? If they fit better that way, then boards may not have been facing the jig correctly when dovetailed.

I have. The Leigh jig has you mark the inside and oitside of the boards so they fit correctly. When I flipped them, it got worse. I think I’m going to try a big sanding belt glued to some mdf and see if I can flatten it down.

2 small things to add -

a belt sander is a very easy way to fix that - if planes are not razor sharp, the outcome may not be great.

I like Ben's suggestion but herein the problem - it may be that your method of cutting the wood was imperfect, or your Square not quite as square as you thought. Worth checking.

Most likely the cause was not having the board absolutely flush against the jig - some pins will then get cut deeper and all will be at a very slight angle.

Thanks for the feedback Rob. My assumption is prob the boards were not perfectly square. I was pretty detailed about having them flush against the jig. I’m hoping the sanding will workout. I’ll post some updates in a few days when I get back on the project. Thanks for feedback.

Thinking about the conceal option - glue in an oversized scrap strip to bring the sides up flush with the end. Then trim flush with hand tools or carefully with a sander. Flip the box and then trim the sides flush that sit proud against the ends. I don’t think the glue-up would be noticed by anyone.

Along the same line as Elmaduro... is it an option to move the bottom of the box up? You could then cut away the bottom edge of the box to create feet at the corners that could be leveled easily with your sanding setup.

It will actually have some rails at the bottom, so the bottom of the case is not that critical (I.e sanding would suffice). I’m going to try the L fence setup, then trim the opp side parallel. I believe this would be the quickest option. I then plan on sanding on a large flat surface at the mating edges of the lid and the box. I think this is prob my best approach given all of the options within my skill set . Thanks!

So I went with a large sanding board (25” x 60”). Some elbow grease and it worked out well. Thanks for all the help!

You've got to be mighty pleased with the result!

Thanks!

SWEET!

Thanks!

That is exactly how I solve this on my smaller boxes.

Please share the details on how you constructed the large board?

I typically use a 1" ply with a laminate top.

To that I use something like the 3M 77 adhesive and full sheets of paper.

I basically did the same, just in a larger scale. I had to buy a sanding belt for a large belt sander and cut it at the seam. I then used spray adhesive to glue it to the Baltic birch.

Did you contact Leigh and ask for their advice?

I have not, but plan on it.

Box with dovetails and wrap around grain looks great. Nice job.

I did find one reference to the offset issue you had in their online manual. It happens when using two routers one for the straight bit and one for the dovetail bit. If the bits aren't centered perfectly in the guide bushing on each router the difference can cause the problem you had.

If you can do that you easily can master a hand plane! Just get religious about sharpening. Lie Nielsen has a great jig sharpening tutorial for free.

Thanks for the advice. I’ll have to do some studying on hand planing. Would have been much quicker I’m sure.

This forum post is now archived. Commenting has been disabled