(Solved) Dowel Joint w 3 Different Angles

Hello,

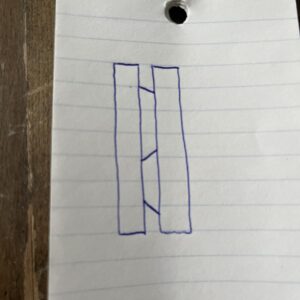

I’m attempting to join 2 boards with 3 dowels, all at different angles, and keeping them roughly 2” apart.

I’m wondering how to do this or if this can even be done.

The angles and locations of holes/dowels in the photo are just a general idea.

Any ideas would help.

Reference photo below.

Thanks in advance,

R

Replies

It seems to me the biggest issue would be the opposite angles makes it pretty impossible to actually insert all 3 dowels into the second board, I feel like it'd catch pretty quick and be impossible to insert enough to do much.

Maybe if you were to drill the dowel holes on the first board slightly oversize to allow some wiggle in the dowels? With trial and error maybe you could get enough play to get the 2nd board on as far as you're hoping, and then fill the oversize holes with something like epoxy or glue/sawdust.

No idea though, what if you just drilled the 2 that are the same direction at least as that'd probably go together a little bit easier, and have the 3rd opposing angle just attached for aesthetics only? If it's only seen from one side you could cut in grooves on the hidden side, and just pop in the dowels that way?

Hopefully somebody else has a better option for you, good luck!

Physically impossible as drawn if you intend for the dowels to be more than cosmetic.

You don't give any dimensions so it's hard to suggest alternatives, other than what Nick93 offered, put the 2 outer dowels in and the center dowel becomes purely cosmetic.

If there is any scale to your drawing the boards are about 4" wide. For this to be sound structurally I'm guessing you'd need about 1.5"-2" of dowel buried in each side of the "joint".

To make this without math and/or a day of buiilding jigs, use a long drill bit to drill the 3 holes all the way through a 6" wide board, rip out the center 2" gap, assemble the doweled "joint" by driving dowels from the outsides-in, and finally glue on extensions, covering the holes on both edges.

What's it for?

Oh I like this, thanks for being smarter than me!

I'm also realizing you could just rip a slight bit of the edge off before drilling holes through, so you can glue it back on after the dowels are inserted and it will be almost invisible if the grain works with you.

Also, I think I'll be stealing this idea when I get a chance.

Genius! That will work perfectly.

I’m making a chandelier to match the table I built.

Started as 6” boards roughly 3/4” thick that I shaped to follow the wood grain so they are no longer rectangular.

Boards are walnut so I think I’ll rip out a 2” piece like you said to drill all the way through then replace the gap with a lighter accent wood.

Thanks again so much, and to everyone else. Much appreciated.

R

For anyone interested how this turned out.

Still some tweaks to figure out, might attach some batter powered LED strips on top of the larger two panels to reduce the shadow.

Thanks again for the help.

Merry Christmas,

R

Thanks for circling back!

Love to see it when done, please come back and post a photo.

Certainly, will do.

You're making your own version of a T-stud