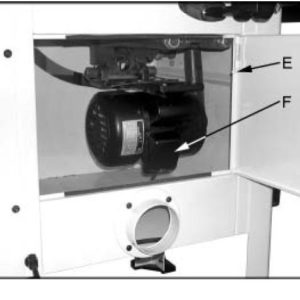

I have a hybrid saw from Jet(2002 vintage – JWSS-10LFR). It was purchased used from a local dealer. The saw works fine but has a bit of a dust collection problem. The saw has a false bottom below the motor. Below that is the space that leads to the dust collection port. See attached image. It doesn’t look like but it DOES have a false bottom. This false bottom has slots and holes for the dust to “flow through” and then out the collection port. Ths problem is that the debis from the sawing process is sometimes bigger than the holes and they eventually get blocked.

At first I had a 1hp Delta dust collector and then decided to purchase a more powerful one…a 2HP Jet collector. But…this problem persists. So I’m wondering if I can remove the false bottom. Does anyone have this saw? Did you have this problem? How did you solve it?

I hate to start “butchering” the cabinet in order to get the dust collection to work. I wold also hate to layout big bucks for another saw. Any help appreciated!

Jim

Replies

little holes, big dust

Have you talked to Jet tech support? It sounds like the design concept was to create smaller, high-speed air vortices within the motor chamber. But, that apparently doesn't work well. The support folks may have suggestions for a fix. Other than buying a 45HP Binford dust collector, that is. ;-)

It's designed that way to prevent those "long" cut off strips from plugging up your 4" line someplace where it's not convenient..

Much better to open up the back of the saw than track down a line plug up.

Jet Hybrid Dust Collection

Jim,

You would think that as Jet have a line of dust collection equipment they would have this perfected. My thoughts would be that the grid prevents larger particles from catching in the hose or at the blower suction inlet - some have a screen.

Depending on the free area, this grid could severely reduce flow to the port. If the open area of the slots is less than 12.5 sq. in. than you will not get the full flow of a 4" duct.

Even with the false bottom removed, you will still see an accumulation of dust and debris in the bottom of the saw. This accumulation will reach maximum levels in the saw body filling in all of the dead air areas. Once these areas are filled, they will all of the dust will flow out the port to the DC - as long as the DC has the capacity.

Don

Well...I just talked to jet tech support. Actually the false bottom that I referred to is part of the body of the saw. This bottom has holes and slots drilled in it that are supposed to let debris flow down into a smaller chamber that is connected to the dust port. This smaller chamber has a removable plastic bottom. Jet told me that some people have removed the plastic bottom and then taken a saw and cut out that portion of the metal bottom where all the holes and slots are located. They stated that this improved dust collection significantly.

I'm a bit concerned that if I do that...that I might be ruining/reducing any resale value the saw has. Oh and by the way...this is a fairly powerful dust collector. I haven't seen anything clog it up...except a shop towel.

Jim

Reduce the value.. IMO it would be something that someone you sold it too would have to do anyway. I wanted to use a 6" direct cyclone line ot the bottom of my 5 HP when I got it. It had a 4" port... I didn't hesitate to cut the opening larger on the outside of the cabinet and add a 6" dust port to get the job done. KInd of like having a new pick-up with nice paint and not being able to haul anything because getting a scratch on the paint will reduce the value. Looks great but virtually worthless in practicallity. haha...

Good luck...

Change of attitude

Don't "butcher" the saw. "Modify" it to improve its performance.

Go for it.

Many such tools, especially older ones, were designed by folks who could address the tool's function, but hadn't the foggiest idea with regard to engineering dust collection requirements. I agree wholeheartedly that you should proceed with the best possible effort to remove the grid cleanly, deburr the cut's edges, and even paint them. The proximity of grid plate to cabinet bottom forces a very sharp turn to the exit, with accompanying loss of efficiency - cut out all you can so as to allow the moving air to find its own most efficient path. You should connect at least one 6" hose or two fours - use all of the collector's available volume.

You can't draw out more air than you allow to enter - there must be very nearly 29 square inches of entry area (same as area of 6" duct) if you're to pull full volume. A slightly lesser inlet area will force higher vacuum, which will in turn pull more air through the blade slot. If the outlet duct is larger than the entry area, then the outlet will starve and its velocity will drop a LOT, causing dropout. If you can, add zero-clearance blade inserts. No nineties - sweeps only - in ducting to collector. A cheapie garbage-can vortex will do an amazing job of removing the large stuff.

Pay attention to hidden entry points such as slots between table and cabinet, slots for adjustment crank movement, etc. Too much undisciplined opening will have air entering everywhere save where it's needed. Use foam and your imagination to close the unwanted leaks and force air movement where it's going to actually pick up sawdust, but be certain that total entry area is about the same as that of the outlet duct.

You want every cubic inch of airflow you can get working at exhausting your saw - at least 600-800 cfm or even more. Can't measure from the picture, but that looks suspiciously like a 4" exit opening. If that's true, then add a second or cap what's there and cut a 6" dia in the bottom. Grizzly has a line of inexpensive plastic adapters that will connect to various duct sizes. You cannot force enough additional airflow through a single 4" connection - no collector has enough static pressure to do that. The area of the main duct at the collector and the area sum of all connections working at one time must be about the same.

If you have multiple tool drops in the collection system, all must be isolated with blast gates so that the full collector volume is available to the saw alone.

If the math has become fuzzy - recall that area is dependent on square of diameter, which can be used to determine duct connection ratios. For example, 6 squared is 36, while 4 squared is 16, and two 4s is thus 16+16 or 32. (The AREA is NOT 36, for example, but the ratio of areas - in this case 36 vs 32 - holds true for compared diameters - the secret to ensuring like air velocity.) Two 4s together are slightly smaller in area than one 6. It's OK to connect two 4s to a single 6 and expect similar total airflow at slightly higher vacuum.

This forum post is now archived. Commenting has been disabled