All,

I scored some really cheap maple at a local Habitat ReStore – apparently some guy was going to redo all his kitchen cabinets with solid maple, bought the stock, and THEN showed his wife the plan. She didn’t like, and he DONATED all the wood (it’d be nice to be a position to do that). Anyway, I picked up a bunch of S2S 7/4 or 8/4 stock for about a $1/bf, and now I’m wanting to make a bed.

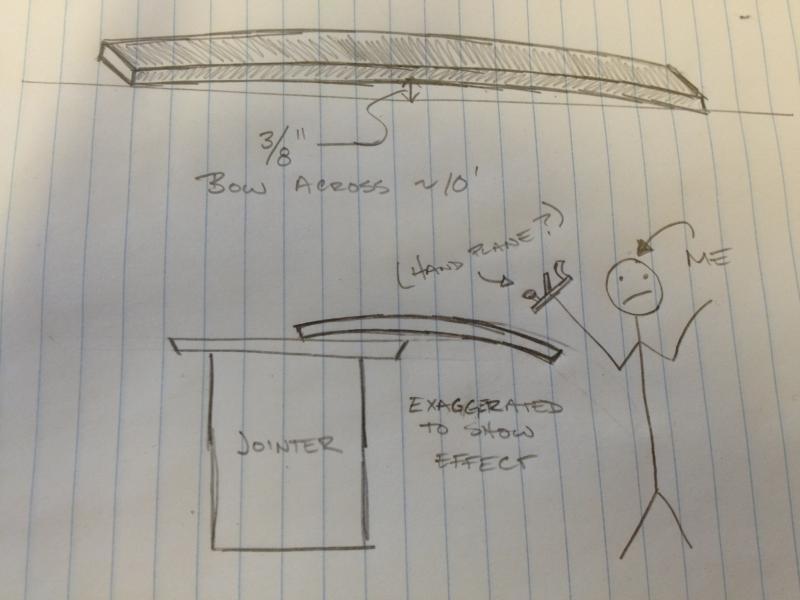

Since some of the stock is about 10 feet long, there’s a bit of a bow lengthwise, even though the surfaces are parallel. When one makes a bed, does one normally face joint the whole ten feet? How does that work if your jointer bed isn’t nearly that long? Or do you do it by hand? Is it acceptable to have some bowing that will be squared out once it’s all assembled? How much is acceptable?

I have access to a jointer that isn’t mine, but even though the width is 12″, the length of the tables is only about 4′, which seems to me that it would be impossible to take the bow out of the board because the two ends will never be on the same plane when jointing.

Hope this makes sense. I’ve attached a highly detailed and technical drawing to demonstrate what I mean.

(My drafting skills can be commissioned if anyone needs to send plans to important government types.)

Thanks in advance for the help.

Replies

Cut to near length first then plane

Use a 2 to 4 foot long straight edge to see if you can pinpoint exactly where the board is bowed. Sometimes you get lucked and it is toward one of the ends and can be eliminated by cutting the board to just a little longer than the desired finished length. Otherwise you still want to go ahead and cut the board close to finished length before planing it. The problem with running a board this long through a jointer (or planner for that matter) is that the downward pressure required to feed the board is usually enough to flatten the board so you never plane away the bend. I prefer to do this work with a handplane since it lets me focus on the high spots a bring those down before planing the entire board. To keep the board from flexing as you plane it you can shim under the board wherever you see day light. Get one face flat and then flip the board over to do the other side.

gdblake

Thanks! That's very helpful

This forum post is now archived. Commenting has been disabled