A while back the blade on my Laguna 14/12 started minor but rapid trackings back and forth on the top wheel (seen through the window). I tried several adjustments and none worked. Then during light work (not resawing) the tracking got progressively worse to the point the front of the blade was moving halfway out the cool blocks and rocking the whole bandsaw in it’s base.

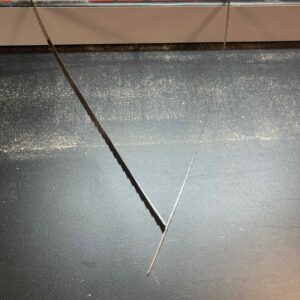

I called it quits and set up for a blade change. When I pulled the old blade out, it already had a kink. When I went to coil it, the blade broke appart in my hands..

The 115″ blade was a 3/4″ premium carbide tip made by Diamond Saw Works and bought through Highland Woodworking. I had the tension set right on the line between 1/2 and 3/4. I’m replacing it with the very same blade and wondering if this a one-off, or did I have the tension too tight? Anyone else have these blades break on them?

Replies

You can’t really tension them too tight. I noticed that when a blade starts wobbling back and forth, the wobbling increases with time and I replace it when it becomes unbearable. If it did that from the start, my guess is that the blade was not straight at the weld.

“[Deleted]”

I went through a few Lenox carbide tipped blades on my 14/12, and they were a major fail. The 3/4" Laguna Resaw King carbide tipped did the job perfectly.

The Resaw King lasted longer, but the 1/2" Highland Woodslicer did just as good a job on resaws as the bigger carbide blade.

It's my opinion that the 14/12 is just a little too small and underpowered for a 3/4" blade. But the thinner blade on the Resaw King is your better bet if you really want to stick with carbide.

There have certainly been enough 14" wheel / carbide blade failure posts out there to make me consider an alternative. I would do the math. If a carbide blade lasts you 6 months and 4 non-carbide blades gave the same duration of service I would probably just do that. Just an idea.

My first resaw king lasted me 4 years.

Is that on the weld part of the blade? I can't tell from the picture but if it is, chances are the blades are not properly welded which is common.

I'd agree with this guy! Tracking issues would result from a bad weld.

I would make sure that your blades are properly tensioned. Tensioning between 1/2” and 3/4” isn’t necessarily correct. Gauges on bandsaws aren’t very accurate and only are useful as a starting point. Tension can easily be measured by pressing your finger against the flat part of the blade and pushing. Deflection should be minimal; like between 1/8” and 1/4” depending on the blade width. There are numerous videos online but I have always followed Alex Snodgrass’s recommendations. Don’t have any issues.

There was another recent thread about this, too, questioning this blade's quality....

All I'm going to say is I think the Resaw King is aptly named.

"Thanks for sharing this information with me. https://brevardcountypropertyappraiser.website/ It’s exactly what I needed!"