Hi Folks,

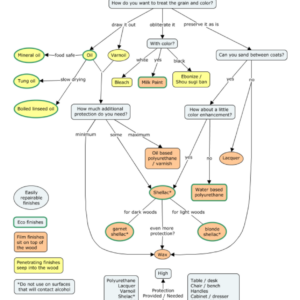

I’m working on a flow chart for to help people decide which finish to use on their piece. I wanted to share a draft with you to see if you had any suggestions, feedback, or improvement areas on the chart. Let me know your thoughts! Hopefully this will become a useful resource for the community.

Replies

“[Deleted]”

I think it's a good teaching tool and reference for beginners. I notice you use the term varnoil, which I assume means a mix, like danish oil? Not heard that term before so wondering if is a regionalism.

I must say the biggest factor i my choice is what do I have on the shelf thats open and needs to be used up.

I here you about using what's open (looking at you Osmo), and yes varnoil is any of the premixed varnish oils out there, watco danish oil, etc

I think you are wayyyy overthinking this.

If I'm like most woodworkers, there is a finish that I use all the time unless there is a specific reason to use another product or method. For me, it's Tried and True Danish Oil, the easiest finish I've ever used and foolproof. But it doesn't work in some situations. A sideboard I'm making with white oak is getting finished with Odie's Dark, an oil/wax combo that claims to have ingredients that react with the tannins in the wood. It too is easy to apply and it only takes one coat in most instances. You adjust sheen by adjusting the final grit of sandpaper, according to the Odie's website.

At any rate, others prefer shellac as a go-to finish, others shout out Waterlox, still others 3-2-1 mineral spirits/oil/poly combination you make in your shop. Then there are the poly adherents, divided into two camps: water-based or oil-based. Etc.

It comes down to what you enjoy using for the experience and because you like the look you get.

Tried and true was my go to for a long while, too

I understand the impulse and appreciate the effort. Finishing is complex, made worse by labeling and marketing practices of profit-seeking enterprise and the millions of internet experts. It’s not easy for relative beginners like myself to figure it all out, and you’re trying to bring some orderliness to it (I think that’s the impulse). Thanks for trying to think it through :)

I hope its helpful. I find myself thinking about what each project needs when it comes time to finish and trying to keep all the variables in my head is too much, hence trying to make a simplistic chart for reference.

WAY too many variables to fit on one page.

Yeah, it is definitely overly simplified, but meant to be a rough guide. Of course, everyone has their own preferences as well.

I asked an artificial intelligence answering machine :

What is the correct finish to apply to wood?

The correct finish to apply to wood depends on the intended use, appearance, and durability desired. Some common wood finishes are:

Varnish: a clear, hard finish that provides good protection and a glossy appearance.

Polyurethane: a synthetic, clear finish that provides excellent durability and a high-gloss shine.

Oil: a penetrating finish that soaks into the wood, nourishing and protecting it while providing a natural look.

Wax: a natural finish that provides a soft, low-sheen shine and protects against moisture.

Lacquer: a fast-drying, clear finish that provides a hard, durable layer and a high-gloss shine.

Shellac: a traditional finish made from the secretions of the lac bug that dries to a hard, glossy coating.

Ultimately, the best finish for wood will depend on the specific project and personal preference.

Ha, nice

Intended Use...first and foremost...at the top of the "food chain"

That is what artificial intel taught also !

It's funny because when I first drafted the chart that was at the top. I had things like table, chair, cabinet, handle, sculpture, etc. Would you say that's a question of durability?

If you’re targeting beginners, I’d throw in steps to try on test piece and also raise the grain and sand.

It’s already a complex and vast matrix , I count 4 axis, Use, Appearance, Durability and Finishes, adding an how-to axis will make it a 5 dimension giant database.

I love flow charts and will also second (third/fourth/etc) the observation that there are just too many variables to make one that encapsulates such a broad spectrum of finish options. But one simple technical note: on the right-hand side where you have sanding between coats, you branched off to 2 different options but did not provide any basis for decision.

Noted, I'll put that in as a durability option

Thanks for all the feedback, folks! Here's a finalized copy.

For someone like me who does not have a lot of finishing experience I appreciate you taking the time and putting in the effort to do this. I like the flowchart as it is easy to follow.

Thanks for your efforts! I think this is a useful framework, and clarifies for a new woodworker the basic framework many experienced woodworkers use to arrive at a finish choice.

There are many different products in many of the categories, and as you can see from the posts, many advocates of one product or another. Marketing and personal experience/testimonials for specific products drives a lot of the discussion about what finish to choose and can obscure the decision about a basic finish type.

Because of this, I think you are on target; identifying a finishing strategy based on the factors you outline is a great starting place to arrive at the appropriate product type. It still leaves the end user to wade through the morass of information about various products within a type (such as "varnoil" or "oil-based varnish/poly"), but it also underlines the fact that those choices are probably less critical (despite what marketers and product enthusiasts may say) than finding one's way to the best general approach for the given project. Kudos!!

The next step is harder: sorting through the products in the various categories! Has anyone tried to take that on in a systemic way?

I think it's great. Whether or not flowcharts are you're kind of thing - we all go through a bit of this (just in our heads) when deciding finishes.

My only input - I used to be a BLO/shellac fan (then another topcoat if additional gloss or protection is needed). But, after lots of tests - I don't really see much difference than just skipping the BLO and going straight to shellac. I like to see as much grain as possible I haven't seen need for BLO if using shellac on top of it. Seems to look about the same to me.

This is helpful to me. Thanks.

This forum post is now archived. Commenting has been disabled