update:

Thanks for all the feedback the shellac I used was the wax and it’s perfectly fine to use under this product I’ve done it before. I figured out the problem it was an old air compressor that had oil leaking into the tank and got in the lines and I did not have a filter on the line and it shot through with my product. I sanded everything down and got a new compressor and everything works perfectly thanks for all the help

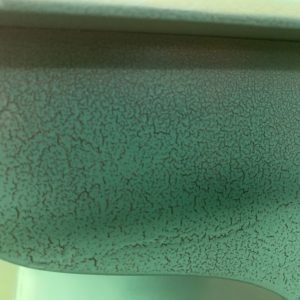

lease help I am new to this forum but I’m grateful that it’s here. I took on a job to refinish some furniture and I have been using Enduro poly on cabinet work for years I decided to use it for this job. I sanded everything down not all the way to Rawood but a really solid scuff sanding on all of the surface of the furniture. I used clear shellac from Zisner as a primer. i sprayed 3 coats of shellac with scuff sanding in between. I am using an HVLP gun with a 1.4 mm tip. my contact at the local store where I buy general finishes indicated that this primer was sufficient I realized in hindsight I probably should’ve purchased general finishes white undercoat however the shellac is what I went with and that’s where I am now. I’ll try to attach pictures but I’m getting this weird separation when the poly dries in certain areas and in other areas it’s giving me this scaly type of finish when it dries. And it’s only on a few certain places for the most part the rest of the services look and appear to be fine. It almost looks like somethings of operating out of the finish too quickly and it’s not allowing for the proper laying down of the solids in order for it to dry correctly and have a clean surface. Any thoughts that you guys help would be greatly appreciated I was actually supposed to deliver this tomorrow But it looks like I’ll have to postpone this at least a day so I can sort this out. Any thoughts that anyone has on the reasons why? I do have a heater set up on one side of the shop and it seems to be far enough away from this project where it wouldn’t have an effect however the surfaces that are giving me problems were the ones that were facing towards the heat source. I think I am going to try to adjust that and see if that makes a difference for what it’s worth. Any help that you guys get offer me I would be so grateful for. thanks for taking the time to read!

Replies

The Zenisser web site says that bullseye is not recommened under p0ly. I did not see " dewaxed" on the lable of the bullseye. I am not a finishing expert, not even a good finisher, but it looks like an adhesion problem to me. I hope all works out.

That shellac has wax in it, and that's what is causing your troubles. Answer makes a dewaxed product, Sealcoat, which is the only thing I would use as an undercoat.

But really, no undercoat is necessary with Enduro.

There's two types of Zinsser shellac. The regular blonde/clear/amber stuff which is most commonly available. That shellac has wax in it. Dewaxed shellac is the stuff that you want if you are going to coat over it. In this case, that's my guess to what happened here. Wrong kind of shellac

Hey,

I work primarily with oils but there are occasions where the customer prefers poly. In those situations my favorite undercoat is sanding sealer. Applying poly over it is no problem regardless of whether I use water or oil-based sealer. The poly will take longer to dry, of course, but I like the results, especially after wet sanding the dried poly.

I suggest you find a scrap piece of hardwood similar to what your project is made from and experiment.

Good luck with your endeavor,

Mikaol

Thanks for all the feedback the shellac I used was the wax and it’s perfectly fine to use under this product I’ve done it before. I figured out the problem it was an old air compressor that had oil leaking into the tank and got in the lines and I did not have a filter on the line and it shot through with my product. I sanded everything down and got a new compressor and everything works perfectly thanks for all the help

This forum post is now archived. Commenting has been disabled