Hello All,

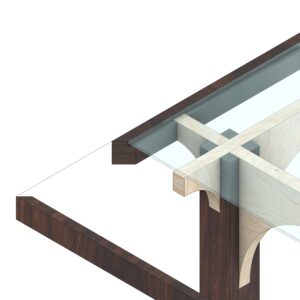

I have been designing a set of very large “conference” tables for an art museum and we are stuck on one small detail. The table top is 1/4″ tempered glass which will rest on oak legs and birch plywood cross-members. The glass will be bordered all the way around by oak trim, which will simultaneously support the glass and protect its edges from catastrophe. See the attached images for more details.

Ideally, we would like to rest the glass directly on top of the oak and birch, but our back up plan is to use silicone bumpers.

The first concern we have with resting glass directly on wood is that the glass could possibly crack. But, obviously we would take the greatest care to make sure that any wood surface touching the glass would be smooth prior to setting the glass top.

The second concern we have with resting glass directly on wood is that moisture could potentially build up between the two. On the other hand, all of the wood will be finished with multiple coats of lacquer, there is plenty of space between the wood members to allow for airflow under the glass, and the museum will obviously be climate controlled.

Does anyone have any thoughts on why we should or should not rest the glass top directly onto wood?

Thanks in advance for the input!

Replies

The only moisture your going to need to worry about it from spilled wine.

Glass needs room to expand and contract because it does and at a very different rate than wood. Your design doesn't appear to allow for that. Is this specialty glass designed for horizontal surfaces? They make stuff that will take the stresses of a table top. It's just not the same thing as what is in your window.. Regular tempered glass at 1/4 " can break pretty easily. You could slam it with a baseball and it might be fine but drop a butter knife and it might turn to popcorn..it doesn't "crack". It's not that much stronger than regular plate at the same thickness ,it just doesn't turn into swords when it breaks.I wouldn't think that the glass in my tempered window would be suitable for a large tabletop. I'd run my design by a glass guy.

I don’t think there's any such thing as glass specifically designed for horizontal surfaces, there’s tempered glass or regular annealed glass. The only option you have for tempered glass is the thickness, how the edges are treated (sanded/rounded, etc.), and regular clear vs low-iron. Chemically tempered glass is slightly tougher than heat tempered, but not enough to be spec’d for a table top. And yes, glass expands and contracts based on temperature, but very little, be sure to leave a gap in the frame. This from a glass engineer: “The coefficient in the table for 'Glass, hard' is 3.3 X 10-6 in/(in F). This means that each linear inch of glass will get 0.0000033" larger for each degree fahrenheit that the temperature increases. If you have 10 inches of glass that get one degree warmer, you can expect it to expand by 0.000033".

Since the expansion happens in all directions, you should do this calculation for the width of your door and for the height. Edit: dont' forget the walls and everything around the door will also expand in the heat.

Example: You have a door that is 3' wide and 6' tall at 72f you want to know how big it will be at 150f.

for the width: 3' X 12" = 36" Temperature increase = 150f - 72f = 78f coefficient of thermal expansion = 3.3 X 10-6 in/(in F) new size = 36" + 36" X 78F X 0.0000033in/(in F) = 36.0093"

for the height: 6' X 12" = 72" Temperature increase = 150f - 72f = 78f coefficient of thermal expansion = 3.3 X 10-6 in/(in F) new size = 72" + 72" X 78F X 0.0000033in/(in F) = 72.0185". P.S. I would not worry about putting the glass directly on finished wood.

I wouldn't have concerns about moisture. But 1/4 inch for a conference table is pretty thin. I'd go with thicker glass.

Thanks for the input everyone. We have been working with a glass specialist. Originally we were considering using 3/8” or even 1/2”, but he said anything over 1/4” would be excessive. At this point the only concerns we have with the thickness are about possible deflection between supports. If deflection in the prototype proves to be too much then we will size up to 3/8”.

Good to hear that others are not worried about moisture aswell!

In ASTM E1300, Standard Practice for Determining Wind Load on Glass, tempered glass is considered to be 4 times as strong as annealed glass of the same thickness. It is not stiffer, but it is able to withstand extreme deflection under uniform load. With a one of a kind piece of tempered glass, my biggest concern would be waviness in the glass due to roller sag a it goes through the tempering oven. More than for strength or stiffness, the thickness of the glass is sometimes increased to minimize this distortion.

Well played sir. I’m in the glass industry and use E1300 all the time. 1/4” is fine as long as cantilevered loads aren’t too bad. Even then it will just flex. The illustration the OP included suggests all will be well.

Just be sure the rabbets are deep enough to accommodate the glass with or without the silicone. And wide enough to allow for seasonal shifting.

Mikaol

Not an expert but for what it is worth:

Glass coffee tables were popular in the 1970s, and many were made more or less the way you describe - a thick sheet of glass in a dry slot.

Yours is a much bigger table so forces will be higher.

I would suggest that the closer to the limits of the glass you will be working, the greater the additional value there will be in using some gasket material. This would reduce the risk of grit getting into the gap or small machining errors placing additional stress on the glass. This last is a minimal consideration, but if you are using a very hard wood then it may be an issue.

I don't think you need to bother with moisture trapping or with expansion of the glass - that will be trivial - we don't allow for it in similar sized window construction after all.

It seems to me that most of the glass inserts in wood tables I've seen have rested on small felt pads distributed around the edge.

This was made in walnut 10 years ago. The glass fits with just a little wiggle room and it's been fine... just 4' long and 3/8" glass if I'm remembering right.

This forum post is now archived. Commenting has been disabled