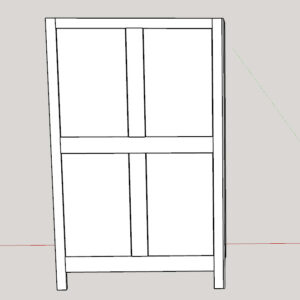

I have a frame and panel back to build for this chest of drawers project I’m working on and am at the point of cutting the panel grooves in the frames. I have a couple Sketchup plans for Chris Becksvoort’s Shaker cupboard and a low chest of drawers he constructed. He used 5/8″ thick frame and panels for the back of both projects and in both cases the grooves on the stiles and muntins are 1/2″ deep and 1/4″ wide. The panels aren’t unusually wide 8 to 10″. The grooves in the top and bottom rails are 1/2″ deep, and 1/4″ deep in the mid-rail. The panel widths side to side in the Sketchup drawing are 1/4″ narrower for expansion, leaving an 1/8″ gap in each of the 1/2″ grooves. The panels in the project I’m working on are ~13″ wide and constructed of 5/8″ thick cherry. So my question is with 5/8″ thick f & p construction do you need to make the groove 1/2″ deep for a reason? Maybe strength? It seems excessive for just panel expansion. Thanks.

Discussion Forum

Get It All!

UNLIMITED Membership is like taking a master class in woodworking for less than $10 a month.

Start Your Free TrialCategories

Discussion Forum

Digital Plans Library

Member exclusive! – Plans for everyone – from beginners to experts – right at your fingertips.

Highlights

-

Shape Your Skills

when you sign up for our emails

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. -

Shop Talk Live Podcast

Shop Talk Live Podcast -

Our favorite articles and videos

Our favorite articles and videos -

E-Learning Courses from Fine Woodworking

-

-

Fine Woodworking New England Event

Fine Woodworking New England Event -

Replies

My default size for frame and panel construction with "normal" size panels (up to about 15" wide) is 3/8" deep grooves, with the panels 1/4" in the groove, leaving a 1/8" gap at each side. End gaps can be much tighter; I typically only leave 1/16" unless the panel is very long. I use a 23 gauge pinner to secure the panel in the center of its space, pinning thru the groove area of the frame into the panel. This means that the panel's shrinkage will be split between the two sides. The deeper you make the groove in thin (5/8") stock, the more leverage there is to break the 3/16" thick wood on each side of the groove. It's possible CB makes his grooves 1/2" deep because that is a common size for 1/4" groove router cutters. I limit the depth with a fence. I use a 2 wing cutter. If I want a clean edge for the groove, I make my first pass only about 1/16" deep; there is less chip-out along the edge of the groove with that shallow cut, and then I cut deeper with a second cut.

That's similar to what I do. I haven't used the router table for making the grooves though. I use a couple 8" Forrest table saw blades made for making 1/4" finger or box joints that work well for making 1/4" grooves.

Look at the joinery, it might just be that he wants a longer tenon at the top & bottom for the frame construction.

Hmmm, could be. The tenons on the muntins are only as long as the groove, 1/2". The bottom rail and mid-rail have through tenons into the stiles on the sides and the top rail connects with a bridal joints. He may have set up 1/2" groove for the muntin and then just used the same set up for putting the grooves in all the other parts.

If the savings in lumber matter you could always lay in a spacer "twig" . I've been that tight on special stock before.

Its fine use what ever depth you want. Its going to be secured the case, so it really doesn't matter.

My comment is cherry for back panels rather than a secondary wood? Plywood for panels? They would have used it if it was available 150 years ago....................

True. Just curious why CB chose 1/2" groove.

As far as cherry for the back, you're right. I didn't buy any additional wood for the back. It's made up of all the leftover cherry scraps, some with defects or sapwood, from this and previous projects I had laying around for some "future" project. My wood racks are full right now. I don't mind using it up for this purpose even if it's a bit over the top and not traditional.

The groove depth is meant to accommodate panel thickness.

However, there’s a formula I found to determine how panel length and groove depth are related. You can use this for your calculations.

Panel width = Rail length - 5/16”

Panel length = Total door length - (door rail width * 2) + (groove depth * 2 ) - 5/16”

This forum post is now archived. Commenting has been disabled