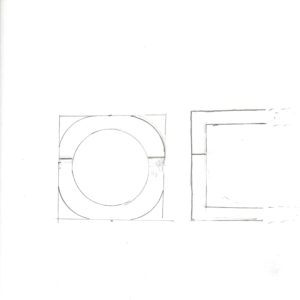

hollowing out a piece of stock and squaring off the ends to leave a tubular space inside a box. to create container hold round objects . like a wine bottle . in this way the ends do not have any joinery giving the box an extra craftsmanship and value . I was thinking of using a round nose router bit to hollow the center then some sort of round dado blade to square off the ends . I have no idea if such a tool exists or if this might be something that would have to be custom made ?

Discussion Forum

Get It All!

UNLIMITED Membership is like taking a master class in woodworking for less than $10 a month.

Start Your Free TrialDiscussion Forum

Digital Plans Library

Member exclusive! – Plans for everyone – from beginners to experts – right at your fingertips.

Highlights

-

Shape Your Skills

when you sign up for our emails

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. -

Shop Talk Live Podcast

Shop Talk Live Podcast -

Our favorite articles and videos

Our favorite articles and videos -

E-Learning Courses from Fine Woodworking

-

-

Fine Woodworking New England Event

Fine Woodworking New England Event

Replies

You don't say how big this piece of stock is. It makes a difference. They do make large size forstner bits but, they tend to be pricey. However, I think the best way is on a lathe, if you have one.

I’m guessing someone else will offer a bit more definite answer for you...

First solution would be a lathe IMO by a long shot.

That Forster bit (wine bottle) would be salty and would require a pretty low speed in a drill press. The largest I ever used was a 3 1/2 inch forstner in 2 inch thick birch. Any harder wood might have been a real challenge.

Material? Depth of the hole? Diameter something in the range of a wine bottle...

Sounds like you have a router. Can you drill out (hog out) the bulk of the material inside the hole, say in a drill press (easier to control all...). Then construct a jig to mount to your blank including a circular template from hardboard to sit a circular router base inside of so the movement of the bit (a straight bit) will allow you to slowly evacuate the waste? Guiding off the template? Or better yet a bit with a collar or bushing and fab the template to guide the bushing? All Easier with a plunge router tho.

I’m about to try a down cut 1/2 inch end mill bit in a big VS plunge router to evacuate most of what will be a sizable square hole. I need more depth than I can get with a straight bit. A few thousandths Of depth at a time in my case. I’ll clear the bulk of the waste with a drill. Piece too big to use a drill press... Hope I can keep my arms attached to my shoulders though. I’m counting on a template to make that happen. We’ll see. Haven’t done it yet so won’t recommend it.

Curious to read other comments. Best wishes, and thanks for the idea. I like the wine bottle base idea.

Not sure what you mean by the "ends not having joinery" and unsure why that would add value, but from a quick glance at your section sketches you are making tubes? To me the round ones if made in quarters instead of halves could be excavated by cove cutting at the tablesaw and glued up after. We could help more with a decent drawing.

This forum post is now archived. Commenting has been disabled