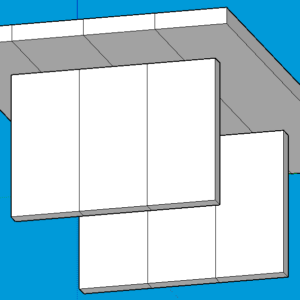

I have a 120cm x 70 cm by 4cm thick coffee table top, and want to attach two massive 35cm x 50cm x 8cm legs underneath. See picture.

What would be the best way to do this?

Could I just use some dowels and glue it, since the grain all goes the same way and so to will the seasonal dimensional changes? I fear that is a bit risky.

I was thinking of routing out a fitting space for it to slide 1cm into, and then using some of those usual table top connectors that allow for some movement, to hold it in place. But will that be a solid enough connection such that the table will not wobble end to end?

Or?

Replies

As-is a VERY well done sliding dovetail has a chance of survival. Adding a stretcher would help a ton... even a short one up high where you would not see it. Dowels are doomed to fail.

Thanks. I was, with no good reason, trying to hold the look minimalistic. But indeed, a stretcher would be one good way to go.

I will expand on what mj said. Retaining the appearance in your drawing, I believe it would be best to make a full length and depth mortise and tenon (with a small shoulder). If you don't want the end grain of the legs to show on the top surface, make the mortise almost all the way through. Even with this, any undue forces, like someone sitting on it or leaning on it, could create racking forces that will break it. A pair of stretchers to supplement the m&t will add a lot of strength to the joint.

Assuming the legs are hollow in the middle, or made hollow, I would screw two heafty tenons, say 1 1/2 inch thick X 3 inches wide X 18 inches long on the underside of the tabletop and slide the hollow leg in from below and secure the leg with a couple of screws .

I don't think a full- length tenon would hold up because the joint would be mostly end grain to long... but a series of 3" stub tenons running with the grain at the depth bilyo described...maybe 4 or 5 of them could do the job.

Might be enough even w/o a stretcher if cut with a shoulder and fit tight enough.

I think the sliding dovetail is the way to go. With those thicknesses you cam make it heavy duty. Pull two halves of the top together in the centre, but make sure the ends of the dovetail don't meet at the closed end before they should. If it is a nice snug fit, just glue, clamp like hell, pray and hold your tongue right. You may not be able pull a dry run apart. May just need a few inches glued either side of centre in the dovetails and the edges of the top pieces.

Just curious... what kind of wood?

With 8 cm thickness, there is no bending load on these legs if they are kept in contact with the underside of the top. You could use large keyholes brackets recessed in the top of the leg and large pan head screws on the underside of the top and slide the legs sideways until snug, you could even use floating shelves brackets screwed to the underside with set screws in the legs to keep them from falling. Even knock down hardware suck as a zip bolt would work.

Approximately converting to imperial, that is a 4-foot by 2 foot, inch and half thick top on a 14 by 20 by 3 inch thick base. I assume the 20 is horizontal, and the table is 14 high. Correct? With that arrangement, the area under the table is pretty useless, so placing a full length and full width stretcher of whatever thickness in the middle would not affect the use nor appearance. If you are fixed on some appearance requirement, you might want to use metal embedded in the components and then covered. Everything gets easier with that amount of material choices.

I’d consider joining the legs at the top with hefty stretchers (won’t really be visible) and then across near the bottom, where most designs have stretchers. This would create a stable base you can then just lay the table top unto and attach from the bottom.

I'll suggest one more way. Make a three sided, dovetailed box by attaching a piece at the top of the legs that's as wide as the three legs. You can decide if it's fully visible (through dovetails) or blind dovetails. Perhaps a narrow cross-piece at the bottom the legs in the middle of the three might help as well.

I think you are risking failure if you don't install some sort of bracing to resist racking forces on the legs. A stretcher, which could be installed anywhere between the legs (as mentioned, hardly visible if at the top) or triangular braces at the top, in the middle of the inside corners between the top and the legs. The wider the stretcher (top to bottom), the more effective it will be.

I also second the vote for multiple stub tenons rather than one long one, and am sure it would be stronger in the long run than a sliding dovetail. If you use stub tenons, keep their thickness thin enough that you don't run into cross grain issues between the side grain of the tenons and the long grain of the mortise openings. (In other words, don't think that making the tenons 3" thick of the ~3.5" thick legs makes them stronger. Expansion and contraction over that thickness can loosen the glue joints.) And also understand that if you do the stub tenons, your glue surfaces are the narrow cheeks of the tenons and the narrow ends of the mortises, not the wide ones.

@jharveyb, I don't think I described the stub tenons properly... I am taking about a series of 3" x maybe 1.5" tenons running across the thickness of the legs. The 3" would be long grain to long grain. This would leave about a 1/4" shoulder to resist racking.

The legs and top as pictured will expand and contract together.

I think I do understand your idea for the stub tenons. I would make them shorter than the 3" with a bigger shoulder. The glue surface is indeed long grain to long grain, but the mortises are fixed length along the 3", and the tenons are changing length along their 3" length, if only a bit since 3" is not seriously long. People seem to ignore the cross grain construction inherent in a mortise and tenon joint, where the tenon (of an apron, for example) changes width with the change in width of the apron, and the mortise doesn't change in length along the length of the leg. I keep my mortises and tenons to about 2.5" in "length" along the width of the apron, and use a non-glued haunch to keep the rest of the apron's width properly located.

I think the drawing is misleading, the top is half as thick as the legs that are 3 inches thick, there is no need for rails if the legs are fastened to the top underside they offer as much surface and width resisting racking as a pedestal. You could imagine having threaded inserts on the underside of the top and the legs could be bolted .

As is, the design could collapse if force is applied to one end. Possibly solution is a butt joint stablized by angle brackets. A pair on each side of each leg will do as much as a stretcher would do and will require no design work.