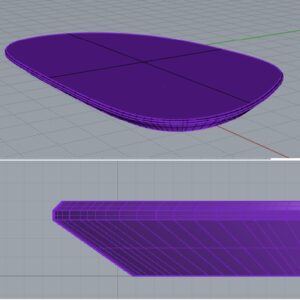

How best to create a large bevel on an irregular shape?

I am making a 120cm x 70cm (47in x 27in) coffee table for my kids, using 4 cm thick planks. The plan view is an irregular oval. For the edges, there is an outward bevel of several mm, then a vertical section of several mm, and on the underside, eg for at least 3cm of the thickness, a inward bevel at around 35 degrees.

I am looking for the best way to cut and smooth this bevel.

Some relevant tools I have: a 600 watt router, a 14 inch bandsaw, consumer table saw, and some hand planes. Any advice will be welcome!

Pictures below.

Replies

You could see if you can find a chamfer router bit that will do what you want. A quick search on MLCS, I found a 22.5 deg bit that has the cutting height you need to get the 3cm. There is also a 30 deg bit, bit the cutting height is only 1 inch, so less than the 3cm you need. You might find a bit on another site that gets you closer to what you want.

https://www.mlcswoodworking.com/shopsite_sc/store/html/smarthtml/pages/bt_chamf.html?zoom_highlight=chamfer

Cut the flats on the Tsaw and the curved corners on the Bsaw. Clean and refine the outer edge with the handplanes & a sanding block. Cut the bevels not-quite all the way with the router. Final shaping of bevels with the handplanes.

Good excuse to buy a spokeshave!

I've done this a few times...the hard way. Dozens of relief cuts with a ryoba, chisel out the waste, then refine with hand planes and spokeshaves.

I'd likely go something along this route. I primarily work with hand tools so I don't have a router option available to me. Depending on how much material I need to remove, I might just start with a scrub plane and see how fast it goes. I also really enjoy creating bevels by hand.

If you go with a chamfer router bit, build a large, long router base with a handle so the router is fully supported and stable as you rout the profiles. Also rout the bevel in multiple small passes and if you’ve never made this cut before, consider practicing on a test piece.

I have made an extended router base out of pegasus and just hold it down on the top as I cut the bevel. Hand is several inches away from the base, no safety issue.

Killing a mythical winged horse for a router base is cruel.

Hey, I'm old. But I never liked that horse anyway. Good catch!!

I usually rough out with a router bit, or even a panel raising bit, then a plane and spokeshave. For detailed shapes like a cookie corner or porringer top, 8ll use a rasp at the end.

Remember, the underneath doesn't need to look pretty, but it should feel nice.

Is the top a single piece or joined boards? On your bandsaw all of this could achieved if you precut the boards before you joined them. Otherwise, its a large piece,if you could fabricate some kind of support on the outer end of your bandsaw you could do your cuts from the outside of the blade. I wouldn't do either of those myself - I would probably rough the whole thing out with a handheld jigsaw( mine will tilt both ways) or in another life, a bowsaw, and finish up with whatever combination worked of spokeshaves, planes, files, rasps, sandpaper glued to chunks of wood or most likely a cardscraper.

Setting up with a router for complicated stuff is time consuming and has the ability to wreck a an entire project in the wink of an eye. Each variation may require a different over priced bit as well. If you use a table saw to begin your bevels and then cut the curves, visually the boards will appear thinner in the center and get thicker on the ends. You'll end up doing a lot of hand work no matter what. Sometimes you can spend more time thinking about how to do something with a machine than it actually takes if you just revert back to hand tools.

Might I suggest looking on the bay, or borrowing, a drawknife. A sharp one will make surprisingly quick work of roughing out the bevels on the curved surfaces, especially the big one on the bottom. Clean up with the planes.

I would first bandsaw the tabletop to shape and sand the the edges square and smooth. I would then use a 30 degrees chamfer bit to shape the larger chamfer and use hand tools and sanding blocks or rasp to make the smaller one.

Thanks all for the ideas! The top is made of 4cm (1 5/8") thick planks about 12cm (5") wide. I do not think I will try to cut the bevel on the bandsaw - it will probably weigh 30kilo / 66lb at least, and its big! I will also think about the chamfer bit, but my router is probably not strong enough, and does not work with 1/2" (12mm) shanks (but it is a good excuse to buy an new router...). I suspect roughing it out by depth with a router on a good support, and working on it from there would work. Would a belt sander, or power hand planer be unwise? My gut tells me it might be good for taking off the real rough edges after the router work, but the last parts need something more gentle with more fine control.

Power planer for the rough work is a good plan, you could skip the router entirely.

Don't even think about using a large chamfer bit in a 1/4" shank router! The head could fly off and kill you. A friend had a 1" ball mill with 1/4" shank in his router; when he touched it to the wood, it broke loose and buried itself in a brick wall (fortunately not his flesh.)

You could set up a saber saw with its blade angled to 35º and a guide fence (guiding off the bottom so that if the saw wanders away from the edge of the wood it leaves extra wood rather than taking off too much.) Then refine with your hand planes.

This is not a large chamfer bit, the 30 degrees angle , one inch cutting height leaves about 1/2 inches wings, it can easily be handle a 1/4 inch shank and if the router is underpowered, it can be lowered gradually to take lighter cuts.

I second the recommendation for drawknife followed by spokeshave. Be sure to mark edges of the bevel on the side and bottom of the piece and work to the marks, and be sure to work downhill on the grain as you go around the piece so you don't tear out a chunk that goes across your lines. You will be surpised at ahow quickly this can go with sharp hand tools, and it is fun, quiet work. You certainly could hog off some wood at first with a power planer. If you don't have the spokeshave and drawknife, you'll be glad you got them, an be more likely to get regular use out of them in the future than an expensive specialty router bit.

This is one way to do it where you also is free to choose the angle of the chamfer. Jig/set up idea is mine but picture is from the one I helped coming up with the idea. https://pin.it/3cdC5ED

Perfect!

My project was delayed, and I am glad I returned here to fine this simple, but working solution. Thanks.

“[Deleted]”

Do you know about scratch stocks?

https://youtu.be/8mVY2-AAaHI