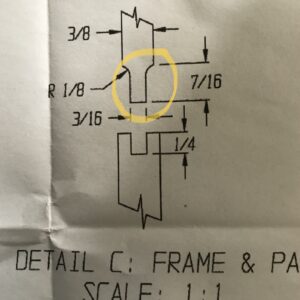

I’m going to be starting a project where I need to route a number of panels with a 7/16” tongue that has a 1/8 “ radius in the inner corners. I have a trim router but have only cut dados and grooves with 90 degree corners. Anything involving a router leaves me scratching my head. Can anyone walk me through the process? Any guidance would be much appreciated. Here’s a detail from my plan:

Discussion Forum

Get It All!

UNLIMITED Membership is like taking a master class in woodworking for less than $10 a month.

Start Your Free TrialCategories

Discussion Forum

Digital Plans Library

Member exclusive! – Plans for everyone – from beginners to experts – right at your fingertips.

Highlights

-

Shape Your Skills

when you sign up for our emails

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. -

Shop Talk Live Podcast

Shop Talk Live Podcast -

Our favorite articles and videos

Our favorite articles and videos -

E-Learning Courses from Fine Woodworking

-

-

Fine Woodworking New England Event

Fine Woodworking New England Event -

Replies

That's not a task for a trim router. You should use a table-mounted full-size router with a half inch collet and a box core bit buried in the fence. The panels would be run past the bit standing on edge on the table, not laying flat.

^^^^ MJ's way is the most efficient.

If you want to do it with a trim router, it will require multiple passes and 2 different bits - a rabbeting bit and a cove bit.

Even with this method, it would be best to mount the trim router in a table.

Mike

You could use an edge guide with your trim router and a cove box bit.... I built an edge guide for my trim router and use it on the jobsite for things like this all the time. I'd probably use a table saw, but you could also use the trim router, to cut a rabbet on each side of the panel, then do the round over in the corners. You could cut the grooves first, as well. Not sure which would be better....

It would almost always be safer, and much quicker, on a router table. In this particular situation a table makes a lot of sense. They make vertical panel bits for just this kinda thing, Although, I haven't gone searching for one that is straight with a 1/8" radius on the end, I wouldn't be surprised that it's available.

Thanks everyone for your tips. I have a small router table built for a compact router but even with that, the potential for making a mess is a little too high to risk. I may just change the design a little. The round over is just to make a small panel stand away from the frame it’s going in..

I think my fellow poster may have been a bit too discouraging in there replies and while yes I would make this cut on my router table it is within the realm of a trim router with the proper setup.

First you need an ⅛" radius bowl bit with a ¼" shaft Amana part #45981 will do the trick about $30 on Amazon. This bit cuts both the rabbet and the radius and will do your design in as few as 2 passes.

If you have a router table that is the way to go. I don't know why you feel there is too great a chance to make a mess, I'm assuming you don't mean too many wood chips. A router table is one of the greatest tools in your shop you should learn to use and appreciate it. You can make this cut in 2 passes but I always like take a feather cut on my last pass to get the best finish so I might do 3 taking just a 1/16 or less on my final pass.

A decent quality trim router can cut ⅛" in most hardwoods in one pass so it's simply a matter of adjusting the fence to make the first cut on both sides of all the panels then move it to either the final setting or just shy if you want the best finish, make another pass or two depending on you preference. Just remember always move your stock right to left on a router table and devices like feather boards can really improve your cut.

I encourage you to go this route it may help you overcome some of your trepidation regarding routers and router tables, indispensable tools in most shops.

I haven’t used a router enough to have much confidence. I think I’ll try your suggestions and make a few practice cuts. Recently I picked up a Veritas router table for trim routers and it’s helped a lot with the simple stuff like grooves and dados. I really appreciate your comments.

What you will be doing is just cutting dados at the edge of a board very simple.

Start by setting the cutting height of the bit. Do this by test cuts in scrap of the same material as your panel on both sides raising the bit ever so slightly, remember when you cut both sides any change is doubled, until the panel fits perfectly into your groove. Once the bit height is set it's just fence adjustments.

I would start with maybe 5/16" back of the the front cutting edge at top dead center to the fence. The Amana bit I mentioned should cut a flat of about 1/4" plus the 1/8" radius. Make all the passes around your panels cutting endgrain edges first, it helps cut down on tear out, followed by the long grain edges. Do this on both sides of all your panels. After this is done move the fence back another 1/8" and repeat the process. You will be surprised how quick it goes and how easy it is. If you can use feather boards attached to the fence to keep a consistent downward pressure on the work piece this will help insure a more consistent cut and add a significant degree of safety. Just make sure the pressure is at least partially being applied to the full thickness portion of the work piece so that it does not tip it into the router bit.

What @esch said.

A less simple alternative with cheaper bits is to cut the cove first. 1/8 core box bit will cut fine to it's full depth - it's only 3mm or so. You can easy do that in a single pass.

Set up with the router table fence to align the cove, run all coves. Change to a 1/4 inch cutter (worth spending on a good whiteside spiral upcut) and move the fence across to complete the tongue in gentle increments.

I'd use the tray bit though - they have many other uses.

Is the 1/8" radius needed on both sides of the panel? If not, your router learning curve could be reduced by 50%.

Consider setting up your router table with a core box bit with the fence registered to make the channel at 7/16" on the panel. Rout the channel along all four sides and backcut the crossgrain to avoid blowouts. Support the infeed and outfeed if the panels are oversized to the table.

Then remove the rest of the stock to reveal the tenon and the roundover.

There are bowl-bottom cleaning bits that would have that bit of curve on the end of a flat cut. like this one: https://www.amazon.com/Yonico-8-Inch-Diameter-Template-Router

This forum post is now archived. Commenting has been disabled