How flat does my plane need to be?

Relatively new to woodworking (less than a year at it so far), it’s more than fair to say that my introduction has been quite a learning curve so far. None the less, with a bit of determination and community support, i’m slowly progressing!

Now that I feel confident my previous head scratching around flattening and sharpening my hand tools has come to an end – at least for the moment – (having recently purchased a new hock blade; good to go out of the box, but decided to add a secondary bevel and bring the shine up a notch), I find myself, once again, struggling

with my shooting board. The issue is I still cannot get anything more than a faint whisker off of my end grain (i’m truing up some 18mm x 140mm beech). And I don’t even mean across the whole length, it comes away in tiny wispy shavings. With the blade set any deeper it will ‘chug’ for want of a better term. With a what I consider to be a bloody sharp blade, i’m slowly wearing a hole in my scalp with my index finger.

So, could it be my plane? My shooting board? Or maybe my technique?

My plane Sole

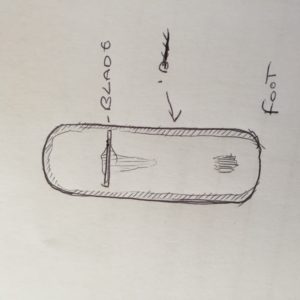

I flattened the sole yesterday (kind of…) I’ve attached an image of a hyper realistic sketch (uh hmm) for your reference. The shaded parts are essentially hollows. The ones in the middle, at the foot and around the blade weren’t shifting much when flattening, and as most of the sole was flat, I figured this would be sufficient enough, as this larger flat area is what the plane will be resting on. Am I wrong? Is it essential for the whole sole to be flat?

My shooting Board

3/4 inch plywood, 1/4 in rest, 3/4 inch plywood stop.

Definitely square.

The bit where the plan runs has 3 coats of poly lacquer.

As always, thanks for your support!

Replies

First, what size plane are you using? If you are working with a small plane take the wispy shavings as a win and move on with your day.

Since you are new to the craft, I have to say sharpness could be your issue. It was a loooong time before I learned that my freshly sharpened tools weren't, and it took a while to get them there and keep them there. The next time you buy a blade from Hock, use it for a bit before you do anything to it, just for a referance point. (Also, get his matching chipbreaker with it)

On your shooting board, wax the area where the plane runs. Most finishes will stick a little if you warm tbem up, which happens pretty quick on a shooting board.

I have found that pretty flat is flat enough for the sole of a plane. When you flatten, have your blade assembly installed and tightened as it will be in use. Sometimes the pressure of the lever cap can flex the body of a plane, especially a lighter one.

With a new shooting board, it needs to be "broken in." The blade wants to take shavings from the shooting board itself, as well as the work piece. It can only take off so much, because the blade doesn't go the full width. The two plane sides act as depth stop, if you will.

Put a piece of wood in a vise, and use your plane to cut the end grain. Set the blade depth where you want. Cuts on end grain will need to be pretty wispy.

Once it cuts perfectly, you know it us sharp, and set right. Now use it on your shooting board. It may cut a little at first, until the sides hit solid wood. Once it slides b back and forth smoothly, with no cutting, chugging, chattering, you should be good to go. Put your workpiece on and make some shavings.

Hi @_MJ_

Thanks for your reply.

My plane is a no.5 bailey plane.

Ah really. RE the hock blade, noted; in future i'll do that.

RE the chip breaker, I know little about the physics and geometry of hand tools (whilst I've been learning a bit of theory, I haven't learned much about planes yet). Why does a particular chip breaker make a difference?

The interesting thing with the wax is, I saw this tip on a number of sources, but I found I had the exact opposite; the plane was more sticky. Maybe it was because I was using beeswax, but as I've seen others use candle wax I thought it would be okay. I'll dig a bit deeper here. I'd imagine applying wax and then melting with a hairdryer would work, as I've done when using wax for other applications.

Thanks for the tip: I actually did this, after watching a flattening tutorial by good ol Paul Sellers.

The Hock chip breakers are made of thicker steel resulting in less chatter, and are machined for a close fit. The Stanley ones were mass produced and often are not a perfect fit, which is why we get chatter and shavings caught there.

@John_C2 - Thanks, i'll give it a go! "Now use it on your shooting board." do you literlly mean on the shooting board, without any stock on there?

Oh I understand. Thank you :)

UPDATE: I just now discovered that the plane isn't square: As a left hander my plane rides left side down, and the left edge isn't square to the sole! This is probably playing a significant role in my problem (?).

Looking at it it may not be worth all of the blood sweat and tears to get it right. I've considered getting a new plane on a few occasions, and perhaps now is the time to convert my old bailey into a scrub and take the plunge! I'm tempted to get a new bench plane, but also a low angle plane (maybe a block plane) for shooting; any advice?

Hi Luke!

First of all I want to caution you about the slippery slope of buying new shiny handplanes...

I progressed in handtools in a very similar way you are describing, kind of unsure and apprehensive. I bought, and still own, just about every premium plane you can think of because I figured I needed to start with a “perfect tool” that I knew had excellent tolerances.

Several years later, my favorite handplanes are the old crusty Stanley Bailey’s because they are so much lighter and thus less tiring. If there was a case for buying a new handplane, I think the jointer planes are the hardest to find in good shape when they are vintage but be warned the premium jointers are usually seven pounds or more and pretty pricey.

Well, regarding your questions about shooting, your blades are probably not as sharp as you think. I can sharpen several orders better now than when I first learned to sharpen. Most folks have several “aha!” moments over the course of time that elevate their sharpening to a level previously thought unattainable.

As far as your plane not being square, that’s not ultra important because you can adjust the blade to cut square to the shooting board.

I hope you find comfort in that what you’re experiencing is normal and that, if you persevere, hand tools are very rewarding and will enable you to tackle hurdles in the shop with a different mentality than someone who is less hand tool adept.

Take a look at the WoodRiver planes. IMO they are THE best value on the market. Because they are made in China I was very reluctant to buy one but WoodCraft is reputable and then I saw Rob Cosman promote them. I now have 3 - #4, 6 & 7.

My #6 WR is probably the most used plane in my shop. I absolutely love it. I keep a couple blades, one straight for shooting and jointing, one slightly cambered for flattening.

I have no problem saying all of my WR planes stack up quite well against a couple Lie Nielsen's I own. IMO the Lie Nielsen 4 1/2 is the best plane I've ever used, period.

I purchased a LN LA jack with the hot dog attachment just for shooting, but truthfully, I go to the #6. I feel the LA jack is too light for shooting.

That said, probably the one plane of all I have I would not buy again is the LA jack. About the only thing I use if for is cleaning up dovetails, but a sharp bevel down plane will do the same thing.

@BigMike78 - Thanks for your feedback. I certainly can find comfort in it, and before I head out and buy my next plane i'm going to get back to my stones and see If I can figure it out from there. Besides, even if I do end up buying a new plane, my curious brain would never let me rest, and I'd want to know what I was wrong and how to improve it!

@RobertEJr thanks for the recommendation! I've watched a few of Cosman's videos, and I must admit I was curious about his lovely planes. Obviously I don't know planes well, at least not technically, but I've watched enough woodworking on YouTube that I could tell it apart from the similar looking Lie Nielsen. Just from looking at it the quality seems good, but I didn't know they were made in China! Times are-a-changing.

For the moment, i'm mainly practising dovetails, so if I could avoid buying another plane until its absolutely necessary that would be ideal.

Thanks again chaps. I'll be sure to keep you posted :)

@BigMike78 - Thanks for your feedback. I certainly can find comfort in it, and before I head out and buy my next plane i'm going to get back to my stones and see If I can figure it out from there. Besides, even if I do end up buying a new plane, my curious brain would never let me rest, and I'd want to know what I was wrong and how to improve it!

@RobertEJr thanks for the recommendation! I've watched a few of Cosman's videos, and I must admit I was curious about his lovely planes. Obviously I don't know planes well, at least not technically, but I've watched enough woodworking on YouTube that I could tell it apart from the similar looking Lie Nielsen. Just from looking at it the quality seems good, but I didn't know they were made in China! Times are-a-changing.

For the moment, i'm mainly practising dovetails, so if I could avoid buying another plane until its absolutely necessary that would be ideal.

Thanks again chaps. I'll be sure to keep you posted :)

Sounds good Luke, looking forward to hearing from you.

Hello Luke. Well on the rocky road to learnin' the woodwork now then, eh? :-)

I've just finished making a full-on shooting board with all the bits allowing square shooting but also shooting at various angles from 0 to 60 degrees; and with a donkey's ear for shooting long mitred edges. It even has a separate runway for a sanding shooter!

I learnt some lessons in making it then tweaking it to do what it's supposed to do - which is to take the final wispy shavings from already squared, mitred or otherwise cut edges and ends. A shooting board is a refining tool, not a major work shaping tool. Wispy shavings (or sawdust, with my sanding shooter runway) are what it's designed to take. No hogging off half an inch or making a mitre from a square end!

The surfaces used for the plane to run against and to hold the workpiece need to be flat and smooth. No amount of lubrication will make them work well if they're rough, bumpy or lumpy. Most plywood shooting boards sold commercially use Baltic birch plywood or similar high quality stuff - it's flat, no voids, bumps, spelks and so forth. Is your shooting board material up to snuff? You also need to ensure it's devoid of snags and drags. Once it's all flat, straight and smooth, then wax it.

Waxing it doesn't mean slapping on a great dollop of any old stuff. It needs to be waxed with something having harder waxes in it - something that can be polished to a slippery shine despite being an incredibly thin coat. Again, this is best done on material that is close-grained so it doesn't gather dust and gunge in open pores with still-sticky wax in them.

You also need to ensure that the reference edges that the plane runs against are straight and square. It's all too easy to take lumps out with the plane corner if that plane corner has nicks in it.

The technique of pushing is also important. Don't throw the plane at the workpiece but rather bring the blade up to it, ensuring the workpiece edge to be shot is pressed firmly against to toe of the plane just in front of the blade. Then push hard but smoothly through the (wispy) cut. Be careful, though, not to let the workpiece push the plane away from the edge the sole is running against.

***

A plane sole needs to be flat in it's toe, around the mouth, down the sides of the sole and at the heel, with all those parts co-planar. It can have a very slight hollow ( just a couple of thousands of an inch or so) in the middle of the rear sole (not the edges) and still work properly. If there's a hollow in front of the blade you'll have great difficulty taking a wispy shaving.

I found float glass with very rough sandpaper stuck on to it carefully (no bumps or wrinkles) to be best for initial flattening. Use a finer grade of sandpaper, once the sole is flat, to take off the roughness left by the first flattening sandpaper. The sole doesn't have to be a mirror - just flat. Use candle wax rubbed on the sole periodically to make the plane glide.

Any significant convexity of the sole will making accurate flat planing more or less impossible. Edges, for example, will gradually become concave as you plane them.

*****

New plane? Personally I favour bevel-up designs and see little reason to buy a traditional design of bevel down plane with the complexity of frog, chipbreaker etc.. Personally I think Veritas planes are the best in terms of functionality, price and (quite importantly) resale value. LN are a close second but they tend to cost a bit more - although they too hold their value very well. You'll find Veritas and LN come with flat soles, flat-backed blades and sharp bevels needing only a few strokes on a fine medium to put on a micro-bevel.

I can't speak for the various lower-cost but better designed planes of the last decade, mostly from the Far East as I've never used one. They seem to need a bit of fettling (nothing serious) but don't hold their value so well. In Britain you could consider Quangsheng / Luban planes from Workshop Heaven and one or two other on-line retailers. I suspect it's them that make various others of similar price & spec sold under various brand names.

Lataxe

If you want to go used, look up the Record T5. It was made for use at trade schools. It is slightly shorter than a Stanley #5 but was made with shooting in mind. It has wider sides that are square to the sole and threaded holes in both sides to accept a side handle for shooting. I got mine from Patrick Leach at Supertool.

Hey guys!

I re-evaluated/re-sharpened my blade and whilst i feel it is much sharper, and seems to have improved a little, i'm still have a bit of trouble (if its still not sharp enough, I will of course have another crack, but really can't see what I could do differently). I'm edging more towards the idea that my problem may be elsewhere...

@Lat_axe thanks for your message, your shooting board sounds the biz!

"Once it's all flat, straight and smooth, then wax it." I have some fine furniture finishing wax (Manns bees wax); will that do the trick? And should I bother waxing the whole thing or would just waxing the run be enough?

"A plane sole needs to be flat in it's toe, around the mouth, down the sides of the sole and at the heel, with all those parts co-planar. It can have a very slight hollow ( just a couple of thousands of an inch or so) in the middle of the rear sole (not the edges) and still work properly." Hmm, well there certainly is a hollow around the front of the mouth. I spent a chunk of time trying to flatten it out, but i guess its deep enough that it wasn't in a rush to meet the sand paper.

"I found float glass with very rough sandpaper stuck on to it carefully (no bumps or wrinkles) to be best for initial flattening." I used a piece of 3/4 inch MDF, and 100 grit. Even after 10 minutes or so those mouth hollows weren't budging... I'm i'm going to have to bite the bullet here and get a new one? This is the only plane I have, so it would be too tragic.

Oh and thanks for your tips on buying a new plane.

@_MJ_ excellent, thanks for the tip!

Nos Da Luke.

That plane sole - is it worth the effort? What other glitches will emerge elsewhere in the body of the instrument, eh? Well ... it's worth learning about plane engineering via experience, even if it's bitter experience. :-)

If you do acquire a new plane it is worth thinking about the wider picture. For example: will it hold it's value, as you may want to replace it with something else after you become more experienced. Or you may take up cycling instead and need the money for a new pair of wheels! Are you satisfied to support the makers, their practices and even their country? These things are important to some. Does it do the sort of planing you'll mostly want to do?

Your shooting board can be either a quick & dirty jig that's made just well enough to work or .... you can treat it as practice for making "proper" things and so pay attention to the detail and finish. In all events, the runway needs to be "right" as does the fence. A flat and slippery runway at which you can get the blade of your plane at right angles to the workpiece being cut is the essential part, though. The rest can be rough and spelky if you like; but keep the tweezers and germolene handy.

I include a pic of my vast new shooting board, inclusive of its tank-like wood-slicing instrument. You could always buy a-one o' them tanks, selling perhaps two children and the house to get it. On the other hand, you will be able to buy three children and a mansion after having it for a few years then selling it, as the value of such things seems to go up like they were precious jewels ... which they are of course. Man jewels.

Lataxe

Hey @Lat_axe

Well i'd definitely like to learn more about my tools, but at the same time, right now my main aim is to get to grips with some joinery, so somethings gotta give. I'll end up spending a lot of time figuring this out, and in the meantime i'm not practising doestails. Don't get me wrong, i'm not bailing on it as I think its important (and that aside my curiosity would drive me nuts until I figure it out). I think what i'll do next is sand and then wax my shooting board.

And just to double check: My manns furniture finishing wax, will that be sufficient for the shooting board? And what about the plane; I hear of people using candle wax on the sole.

Couldn't agree more! I'm actually a designer, and decided to take this on to add it to my skill set (eventually). I figured along the way i'll pick up handy tips and tricks that can feed straight into my work (as I have done). So I guess any tools I buy will be an investment. I definitely care about the sourcing of my materials and tools, but of course I have to weigh it up against cost. Its all good investing in home talent here in the UK, but then comes the questions of margin vs competitor products.

Wow your shooting board certainly is the biz! You could almost invent new angles with that thing haha. Image of mine attached. Pretty basic, but its flat and square so I guess that's the main thing.

That's the LN plane right? How is it in terms of weight?

Luke,

Yes, one must eventually make summick, despite tool collectin' & fettlin' being somewhat addictive. When you do, you'll discover just how helpful or a hindrance a particular tool used can be. Some tools just disappear in your hand and become an extension of you. Others are like trying to eat a slippery fat sausage with a blunt spoon lacking a handle. :-)

I can't see what's in the Mann's wax polish but a harder wax for running a metal plane along is probably better than a softer wax. The surface you put it on needs to be as flat and smooth as it can be first ... but perhaps candle wax is ideal, as it certainly works on plane soles, as you seem to know.

A well made tool that not only works as it should but keeps or increases its value is a wonderful (and rare) thing in today's throwaway world. Such things do often require a big wodge to buy; but not always. For example, Narex chisels are inexpensive but remarkably well made out-of-the-box; and performant. Why pay 5 - 7X as much for a Veritas or LN (or even more for Blue Spruce)? Those are all excellent tools (I had some but sold them - for more than I paid) but Narex are that rare thing: excellent yet inexpensive. Of course, you don't get much for a second hand one as a new one is so inexpensive.

How to find such tools? Sculling about places like this but also "the hard way" by buying and trying.

The shooting board is a bit of a plaything really. In truth I can get perfectly square, clean and very accurate ninety degree ends, mitred corners and any other angle on the tablesaw with it's sliding carriage and an 80 toof blade of good quality. But I fancied a play at the traditional modes, so .... the shooting board was borned.

The plane on it is nowt so common as a-one o' them LNs! No. It's one of these:

http://www.marcouplanes.com/Marcou_Planes_22_Handplanes.php

It's a tank, which some don't like and call "planes for Popeye". Personally I find heavyweight planes much easier to use than lighter ones, probably because of their momentum. I yam a big strong bloke and don't mind wafting such a thing about.

Today it would cost you a very fat wodge to buy. I bought that one (and some others) 11 or 12 years ago for one sixth of what they cost now. One day the ladywife will knock me off, when I have annoyed her a bit too much, then cash them all in. Or a grandson will have away with them on the grounds I won't need them soon anyway as I'll be on a perch in the gimmery where man-toys are discouraged by a large male nurse called Biffa.

Lataxe

@Lat_axe

Hmm well I guess the furniture was is furniture wax, so it seems to make sense it would be suitable! But of course i'll get my googly eyes out and see if anyone uses any other finish for shooters.

RE planes: I'm literally on the interwebs having a gander as we speak. I've heard good things about Wood River (and actually they were recommend to me earlier).

What ever I go for I think it would be wise to invest in something new of decent quality, save for finding myself in the same boat, restoring an old gem that needs more love and experience than I can currently give it. It would end up back on the web looking to be re-adopted (with me crying as I type).

Thanks for the details and the links! Naturally the Veritas and LN's pop up all the time, but vs something like the wood river they're almost 2x as much. My heart is swaying towards a low angle bench plane, possibly Wood River (Along with the reviews, I know Mr Cosman uses them, having hand a hand in designing them it seems).

I know what you mean RE the heftier plane. My Bailey has a good weight to it, and I can really feel the weight shift back and forth ever so slightly, but i feel it gives me a greater awareness and better control.

Get in your workshop and hide your tools immediately! In fact, to be safe you'd best delete this message along with your FW account. Then change your identity and leave the country...

Or just give them to your grandson. Actually yes, that's much easier.

I don't mind Biffa, he's a simple and rather sweet man, but he's clumsy and terrifying with a syringe in hand.

UPDATE

So I went and bought myself a lovely new plane (Wood Rivers), which arrived today. After wiping away a swamp of oil and inspecting it, I noticed that one of the edges of the adjustable mouth sits slightly below the sole. Before I get frustrated and send it back, is this 'normal' or at least sufficient enough? Its only about 1 thousand of an inch to my eye, but none the less...

Thanks for your continued support!

That portion of the sole needs to be dead flat.

Luke,

It's not easy to recommend to you or anyone a new plane as others can't know your full circumstances or inclinations, even if explained at length in written forum posts. Still, I feel a bit guilty in not mentioning a bit more forcefully that the reviews of Wood River planes in this very magazine are generally not that good. To put it another way, I would never buy one myself. But that's me not you.

https://www.finewoodworking.com/2015/09/30/no-5-handplane2

https://www.finewoodworking.com/2015/09/30/no-62-jackplane

It may be that you can send it back and get another that's less wonky or even good (rather than just satisfactory). On the other hand, if one is wonky .....

I don't know if you have a subscription to FWW full web content (that $99 a year, with a 14 day free trial) but may I suggest that it's the best buy you can make as it'll save you oodles of dosh in your future buys because you'll then be armed with a lot of FWW information about tools in general and many reviews of specific tools.

*****

As I may have mentioned earlier, try to find the dosh for a failsafe item if you can. An LN or Veritas is failsafe. It'll also keep most of it's value in all liklihood so you can even sell it to obtain money for something different should you wish. A Wood River plane is unlikley to have much of a second hand value, even if it's a good 'un. (I'm happy to be corrected if this is not so).

Lataxe

Contact the retailer for a return. If you can get a woodworking brain on the phone and show them your photo you may be able to have them cherry pick a replacement for you.

Hey guys,

Thanks for your support.

Ah damn, yeah I was weighing up a LN vs The WR, and only went for the WR because of the price. I had read reviews (though admittedly not on here) that said it was a good alternative to such planes, so whilst I would prefer to have the LN i was looking at I went for it! Well, another lesson learned.

I'll definitely send it back, I think just for a full refund. I mean, I appreciate what you're saying about the cherry picking, but if they're having to cherry pick then the product isn't good enough.

Thanks again!

PS. One day in the future, I promise you'll be like proud parents! Haha

Luke,

Price is not a minor factor in choosing these things, especially if you have a family or other important demands of higher priority on the poor ole wallet. This being the case, it's worth trying to find something that at least approaches LN or Veritas quality but for less money - at the cost of your own time & effort to fettle it so its as functionally good as an LN or Veritas.

I hesitate to suggest it - since the suggestion isn't a fail safe buy - but have a look at the Quangsheng planes, stocked by Workshop Heaven and a few others in Britain. In particular, consider the bevel up jack plane in a package with 3 blades giving different cutting angles. The user-reviews of the plane are here:

https://www.workshopheaven.com/quangsheng-no-62-low-angle-jack-plane.html

The package with the plane and 3 blades is here:

https://www.workshopheaven.com/quangsheng-no-62-extra-blade-package.html

If you get on the phone to Mathew Thingy who owns & runs Workshop Heaven, you could probably persuade him to examine any plane you might buy before he sends it, to make sure its not got a serious glitch and is easily brought to a very good standard. He's a bit of an tool enthusiast, not just a pure saleman.

Personally I would still have an LN or Veritas .... but if you can get a good example of that Quangsheng, it looks like a cost-effective solution.

Of course it is a jack plane not a dedicated smoother of 4 or 4 & 1/2 size. But there's something to be said for the jack plane as a do-it-all: smoother, try plane (for shorter edges at least) and even a scrubber. The three blades in that package mean it'll also handle naughty woods (high angle) end grain (low angle) and anything in between.

But you'd need to get a good one...........

Lataxe

Lat_axe in the end I went for the Veritas... only to be emailed and told that it is out of stock (and seems to be everywhere else). Supply issues aside, at least I now know what I want! I just might have to wait a while at the moment.

Luke,

Classic hand tools have a BU smoother.

https://www.classichandtools.com/acatalog/Veritas-Low-Angle-Smoothing-Plane-and-PM-V11-Blade-05P2571.html#SID=1185

Dieter Schmidt seems to have some too:

https://www.fine-tools.com/veritas-flachwinkel-putzhobel.html#ziel308832

And a Veritas jack plane, down this page a bit:

https://www.fine-tools.com/eputz5.html

I've bought a few times from both suppliers and they've been reliable. Dieter Schmidt prices are in euros, which often translates to less than the British retailer sterling price for the same thing, although you do pay a small carriage fee from Germany.

Lataxe

Hey Lataxe,

Thanks for the links. I was actually looking to get jack, being as it will be my main plane now. That aside I did buy my last plane blade from fine tools so i'll probably get the plane from there too! (plus its free delivery).

Cheers :)

Personally I would never by a plan site unseen from anything other then one if the premier manufacturers such al LN or Verias or one of the boutique manufacturers. Their is a reason LN and others charge so much for planes they use very high levels of quality control, And that costs a lot of money.

The lesser companies get a lot wider range of quality and if you can play touchy feely with them then you can find a good one.

That being said if you need to save money go find an old 1950s plane such as those made by Ward or a few others But they may take a LOT of work and bring you full circle to where you started this post.

Personally I am to poor to by cheep. Every time I by cheep I end up having to buy it again or fix it or otherwise have to spend so much time and money that it costs more then if I had saved up and bought a good one to begin with.

But you mileage may very,

I have a 60% rule. If a decent something gets to be 60% of the cost of a "Real" one (whatever that is) I spend the extra 40% and get the sure thing. The price on a Woodriver #4 is $199 and the price on a Veritas #4 is $227. If the other model prices are this close I am confused what makes Woodriver attractive. I would go with a Veritas or a Lie Nielsen every time.

There are a lot of good used planes out there although the prices are getting a little silly. At your stage you in your hand tool journey I would go with a known quantity for the few extra bucks. Now you are 99.99% sure that if there are issues, it is not the tool. That piece of mind would surely be worth $28 to me. JMHO.

Be careful of those who are spokespersons for tools.Cosman was the spokesman for LN and there was NO better product.They let him go and he next appeared at Woodcraft who allowed him to teach at there stores.He is a GREAT dovetail teacher and plane use teacher.Great videos.As to his endorcement of Woodriver products, buyer beware! As with everything you get what you pay for.Go to a used tool show and look at whats on offer

This forum post is now archived. Commenting has been disabled