Hi There,

I couldn’t figure out a way to install 2×4 ledgers on my wall. I wonder if someone could point me to the right direction.

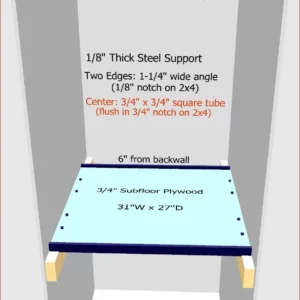

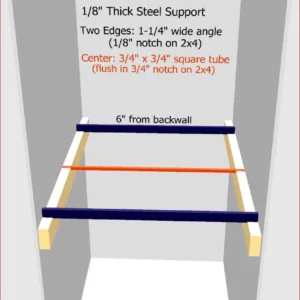

The laundry space is 31″ W x 36″ D. I could attach 2x4s as ledgers, make notches for 3 steel metal support, and lay subfloor grade plywood on top. My dryer is 88lb. I hope this design would be strong enough to support it.

The other issue is that my wall has metal studs. In the past, I used lag screws to attach heavy-duty brackets to the wall of wood studs. What to do with metal studs in this case? I saw plastic anchors are used in some YouTube videos, would they quickly get worn out due to the dryer vibration?

If this platform idea doesn’t fly, I have to come up with my own design of metal stacking kit which I have no idea right now. Platform vs metal stacking kit, which is more appropriate for my project?

Replies

2xs and plywood should be fine, the steel in the center is overkill. I like the steel front & rear because it adds a lip to keep the dryer from jumping off. Fine thread drywayy screws will grab the steel studs, just don't overdrive them. I would add a couple of drywall anchors on each side... the wide screw-in type.

Thanks for your reply! The typical joist spacing is 12”~16”. The plywood is 27” deep, so I thought adding the center support can help reducing the deflection.

You can purchase 2.5" or 3" self tapping screws in a variety of diameters, up to 1/4". I have used #10 self tapping screws to hold cabinets to a wall with steel studs in the past and it worked well. You need to predrill the holes in the 2x4, but they grab the studs very well. These tend to be a beefy screw than the fine thread drywall screws, which also work.

They make steel anchors for these studs, there was a recent article in fine woodworking on this. I have used the anchors rated for 300lb and they would be overkill for this project.

Thanks for sharing your experience with metal studs! Glad to know there are anchors for this kind of attachment. Esch5995 raised a valid concern about vibration causing drywall cracks. Don’t know what to do now.

Buy the stacking kit. You are adding 4" to the height of the dryer controls which most woman complain they can barely reach or see the control panels which are angled up slightly for easy viewing for unstacked installation which are more common.

Your plan will likely result in drywall cracks appearing because though less than washing machines dryers do vibrate and your platform will transfer those vibrations to the walls,especially with metal studs.

Your analysis makes sense. Unfortunately there is no stacking kit existing for this mismatched setup. GE’s official advice is to buy a new pair but my dryer is working fine and I hate to spend another $1000 on a new dryer just because of the stacking kit. I wish I had metalworking skills so I can hack my own stacking brackets. Or I should build a wooden platform to stand on the floor, which needs more skill and materials.

My appliances are compact size so I do have 3” gap on each side. The ledgers can fit in the gaps and its top can be flush with the washer top. But the vibration causing drywall cracks down the road is a valid concern.

Thanks for chiming in!

With that much room on the sides, I would go ahead and make a platform supported from the floor on each side. There would be no issue of support needed, and you could attach it at a couple points with rubber between it and the walls if you wanted to. You would need to figure out bracing so it was rigid; again, you would have room for that with 1/2" plywood.

Good idea. Just lots of materials will be needed to build this standalone platform. Sigh

Since the washer should be able to take the weight of the dryer just make a plywood stacking kit. Size the slab to sit the larger dryer inside a raised rim an add a raised rim below to capture the top of the washer.

If you wanted it in metal it could be made with some aluminum angle stock and screws, bolts, or pop rivets.

This forum post is now archived. Commenting has been disabled