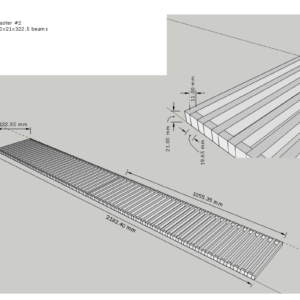

I am building a wooden raster, 7 feet long and 1 foot wide, for our in-the-ground heater in our living room. The design has two pieces along sides which support 64 cross pieces evenly spaced along the length. (see the attached image -this does not show the half-laps, but shows the general design)

I want to use glued half laps to attach the cross pieces resting on the side pieces using half-laps. So that is 128 x 2 half laps, each about a half inch in width and depth.

How can I most quickly make these using a basic tablesaw (I do have a sled), and/or a home made router table (it only has a fence, no tracks), and/or a bandsaw (blades cut a bit rough)?

Mainly I am challenged by: how to repetitively make precise laps along the long pieces

But I am interested in best practices for any aspect of cutting both parts in large quantities.

(I do understand how to a) set my tools to the correct height for these, and b) how to use a stop block to repeatedly cut in the same place using the table sled (but that does not work with a 7 foot length of wood with many slots to make…)

Thanks!

Replies

First of all, you will be cutting a lot of repeatable things. Make sore you do not loose concentration, use all possible safety guards. Next, all your pieces must be have the same dimensions, length, width, and thickness. I did a large grid pattern on my TS and a dado blade for a wine rack but I cannot see from your picture if this is applicable. I used a miter gauge sled with a index stop for your project. Make the first cut, move piece over onto the stop, make another cut, then repeat. Depending on the width you need, you may have to have flip stops to index one side then the other but you can figure that out with a few scrap pieces. I did not need super fit/finish so this worked fine. Other members may have better ideas, but this is what I did.

A sketch of the actual joint(s) would help. Assuming we're thinking long half-lapped ladder... For the long piece make a box joint fixture for your sled or miter gauge and dial in your dado stack for single-pass cuts. Unwieldly at 7' long, but doable.

Leave the 7-footer over long & more than double-width so you only have to do it once and have enough stock left for cleanup. I think I'd start in the middle and work towards both ends.

Make your long parts & last slats wider and with something sturdier than half-laps to form a frame... maybe bridle joints. I'd consider a middle stretcher in something that long. I'd also flip it so the long rails present as continuous & in case you wind up needing fasteners later.

Good point about flipping it over so the long rails are presented. Thanks!

PS: As @esch5995 asked, I am in Europe, and do not have the possibility to use a Dado on my saw.

There are several ways to do this, but my first question, since you are using metric measurements would be, can you use a dado blade?

If the answer is yes a simple one-time use finger joint jig is a good solution. This is assuming you can handle 7' to both sides of your blade. If not then a router is going to be your best tool. To make such a jig simply take a decent sized piece of hardboard maybe 2'x 4' attach a fence to it that is square, but it doesn't need to as square as your cut-off sled, so no 5 cut method needed. Prior to attaching the fence cut an 11mm x 11mm slot 20mm or so right of center. Now cut a 11mm x 11mm pin that is 2"-3"(long enough that 2 boards can register to it at once) or so. Glue this into the slot you cut then attach the fence to the panel. You can now either attach a runner to this assembly it, or for real quick one-time use just attach it to your miter gauge, assuming your miter gauge lets you attach accessories, just be sure the left edge of the pin is exactly 19.65mm from the right edge of the blade. Now cut a 19.65mm spacer, this should be as long as you feel comfortable spanning to hold multiple boards against the fence (a simple hook board can extend your span several inches and let you cut 3-4 additional boards at a time). To use the jig cut the slots in the long pieces first. Hold the spacer between the pin and the boards temporarily and butt the ends to it, holding the workpieces tightly in place remove the spacer and cut the rabets on the ends. Now slide the boards to the right until they index against the pin, make another cut. Now you can lift the newly cut slot onto the pin(it helps to chamfer the top of the pin slightly) and make another cut repeat until all the slots are cut.

Once the slots are all cut attach your spacer with double stick tape, ACC glue or screws as you prefer, making sure it is square to the fence. Now butt as many boards as you feel comfortable handling at once, against this pin and make a cut, flip the boards and cut the opposite end(making sure to cut the same face, don't laugh it happens). Repeat until all the boards are cut.

Thanks esch5995, but I cannot really follow what you wrote. Indeed, I do not have a Dado. You seem to be discribing a index jig for a router table, but its not clear how this would work on my basic router table - with only a fence, that slides back and forth, not evenly. I dont have tracks on it either, so can not use a miter.

But, you did give me the idea to make a double index set up, such that once I have two slots, I can use the two index pins (both to one side space as fitting) to help guide the long rail perpendicular to the router bit...

Here is a router jig to accomplish the same thing. Picture are often better than words but ask if anything is not clear.

PS. The supports on the underside of the jig should be a couple of mm smaller, not taller as shown, than the work pieces to insure that downward pressure keeps the bottom of the jig tight against the workpieces insuring the depth of cut is correct.

Have you considered rabbeting the long pieces and then glueing in the cross members using spacers? You’d need a lot of spacers, but it would be easier and faster than 128 half-laps.

I would want the cross pieces full width for strength, but maybe I could do the same, but just use a half-high long piece, and spacers to fill the gaps between each... need to think this idea over..

Box joint jig for the long pieces. Cut them from one wider piece, then rip that to get two long legs.

Indeed that speeds up the process, if I also had a Dado to make the full width cuts.

I think we are all assuming you have a dado set for your table saw. It is going to be way faster than a router.

Same for the cross pieces as the long pieces; make them from wider boards, rip them from wider pieces after you have cut the half laps on the ends. Easier to rip them to already cut half lap width than to adjust the dado cut to proper width after cutting the cross pieces.

By cutting the long pieces before ripping them apart, it is easier to start in the middle and work toward both ends, as they will be identical even if there is a slight discrepancy between the two directions. Leave the long pieces extra long, and the end cross pieces extra wide, so you can fit the finished piece to the opening.

You can cut the half laps on the shorter pieces with the dado blade and a stop block; set the block to cut the shoulder of the joint, then pull the piece away from it as many times as you need to remove the rest of the waste toward the end of the board.

I really should have added that I do not have a Dado capable saw... which is often the case in Europe... Thanks for the input however.

Curious as to why Dado stacks are not compatible with European saws. Arbor length?

“EU regulations require a specific stopping time for the blade after the saw is powered down.

Because of the increased mass of a dado stack, manufacturers would need to install a far more robust braking system to comply with those regulations.

Rather than do this, most manufacturers instead cut the arbor short and state that their saw isn’t dado stack compatible.“

Good to know. Thanks!

I'd probably rethink the joint design. This seems like a good application for dowels. It would be plenty strong for this application and moving a dowel jig and drill will be much easier than working with a 7ft board at the table saw.

Indeed, but my better half has a design in mind... ;-)

No dado set requires a different strategy.

For the short pieces, use two cuts to create each half lap. One with the board on the sled, against a stop block, to create the shoulder of the dado. The other cut is with the board vertical against the fence, with the depth of cut right to just clean out the corner and remove the waste. Make sure the waste side is away from the fence, rather than against it, so that there is no chance of the waste piece creating a kick-back.

For the 7' pieces, I would use a hand held router, with a base that has a key attached to it that is the same size as the groove it creates. The key is spaced from the bit the distance between the dados. It then operates like the box jigs people were suggesting for the table saw (with a dado set.) I have made some extra router base plates from plexiglas that stick out beyond the router, so I can screw things to the bottom of the base thru the overhang. (You can also use high quality plywood.) I also have made a high fence for my table saw that makes cutting vertical pieces safer, as well as a tenoning jig.

I would expect that a 1/2"x1/2" dado might be a bit much to do in one pass with a router. If you have a plunge router, I would do it in two steps.

You can do this on a table saw without a dado blade using a slightly modified box joint jig. I needed to cut over 1000 half lap joints a couple of years ago and the box joint jig on a table saw is the way to go. I used wide boards and then ripped them to width. This makes everything much faster because you are only cutting 1/5 the number of joints if you get 5 smaller pieces from each board.

On a normal box joint jig, the finger that indexes the next cut is the width of the dado blade and set over the width of the gap between joints. Make the finger the width of you blade. Cut your first half lap joint freehand and make it fit nicely. Place this first cut on the finger and make multiple passes until the the sides of the indexing finger moves across the joint. You will now have produced an identical width half lap. Use a flat top blade and it will look just like a dado blade. This will be much faster than a router, but take more time than a dado blade.

I would just cut the half laps on the cross pieces using whatever technique you currently use for tenons.

This forum post is now archived. Commenting has been disabled