How to stop paint from running through pine wood grain

Hey everyone, and Happy New Year! (almost)

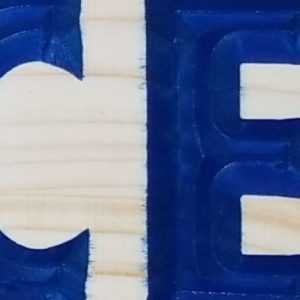

Novice woodworker here. For Christmas this year, I made my brother an engraved and painted sign out of pine wood. I was generally happy with how it came out, but had a few issues with paint bleeding through the grain of the wood. I’ll describe my process below, and would very much appreciate any help that you guys may be able to offer in getting cleaner paint lines / preventing that bleed through the wood grain.

1) I got some pine board from my local big box store.

2) I sanded the board with 60, 120, then 180 grit sandpaper and shop-vac’d and wiped to remove dust.

3) I applied a coat of spray-on oil based polyurethane and let it dry overnight.

4) I applied a sheet of oramask 813 stenciling vinyl, squeegee’d out any air bubbles, and let it sit for two days. (Steps 2 and 3 were to ensure that the oramask had a good surface to stick to).

5) I used a V-bit and CNC router to cut out the pattern on my sign and shop-vac’d out any sawdust.

7) I applied a coat of clear enamel spray paint to attempt to seal the cut edges of my stencil, and let it dry overnight.

8) I applied a coat of each of my enamel spray paint colors and let dry for several hours before removing the stencil. At this point I observed the bleeding of the paint through the wood grains.

9) After observing the paint bleed, I sanded with 60, 120, and 180 grit sandpaper again, removing about 0.10″ of wood off of the surface. This did not eliminate the paint bleed, which is what makes me think that this is bleeding through the wood grain and not just paint leaking under my stencil.

So how would you go about preventing this problem in future projects? Is there a sealer that you would recommend that would do a better job of sealing the grains than oil-based poly? I want it to be clear so that the grain of the wood still shows through in areas where I haven’t painted, and I want to be able to spray paint on top of it. Is there another solution other than a different sealer?

Related question: is there another (commonly and cheaply available) wood that would inherently have less grain-bleed issues than pine?

Many thanks in advance!

Replies

I don't really have a good answer for your query.. but maybe some ideas.

I'm guessing that building up a film finish in the routed stencil cavities would be best. Poly would seem to be a good idea where your essentially building up a plastic coating. If you only put one coat on, that probably wasn't enough to get a sealed finish. By routing into the board, those angles are actually now exposed end grain which will drink up any kind of liquid coming it's way. Spray paint is a very runny paint mixture so the wood would naturally soak it right up. I'm a bit confused though as you said you used an oil poly over the top before your routed but then don't mention actually using the poly again, but that you used a clear enamel spray paint. Obviously, if you only used the poly at the start wherever you routed it's now gone...

As for a common and cheap wood species, try poplar. It takes paint really well and will be more durable and hard than pine.

Yeah I had previously tried using a single coat of poly at step #7 to seal the freshly cut wood, but had run into the same bleeding issue. I switched to clear spray paint because I'd thought that that might sit on top of the wood better rather than soaking in. I'm considering trying to start selling signs, so I was resisting the idea of having to start doing several coats (elongating the process and driving down profit/hr) but it sounds like that might be unavoidable. I'll try multiple coats of poly at that step as you suggested though!

And ok, thanks for the tip with the poplar wood. Any go-to sources for wood that isn't available at the big box stores, or is it mostly just a matter of finding the right small local place?

Thanks for the help!

When you routed through the mask you created edges under the mask that you did not get sealer into. You might try a penetrating sealer at the start instead of the spray, and then a brush on sealer after routing for a heavier application that can be pushed into the end grain in every direction as it is applied. The small "leaks" in your photos are places you never really sealed.

It's always a good idea to do it right the first time even if it takes a bit longer. If your end goal is to be selling product then you want to sell a quality product. Don't worry so much about profit for hour at this point. Don't even think in those terms because it's a losing battle unless you're selling thousands of items. It's the way we all think about these kinds of things, but I think it's best to think about what is this worth to someone and what do you want to get for it.

Where abouts are you located? Hardwood dealers likely have poplar, even the big box stores do sometimes as well, however they charge a foolish amount.

I think the problem was only one coat of sealer before painting. Or, maybe the incorrect sealer. Maybe you need a bit of a more penetrating coat?

The last time I did anything like that, admittedly not exactly the same, but, I put a number of thinned shellac coats before applying the paint in an inlay. It was a really light cut because I wanted it to flow in and fill the grain. But, I like shellac for almost everything! LOL

There are a number of products on the market that would seal the grain better than a spray coat of oil, maybe even better than my shellac.

If all else fails, try using a thin coat of epoxy in the inset area. That will seal all the end grains, and give a solid foundation for the paint. Going back after it dries and scuffing with 120 grit sandpaper will give the paint plenty to adhere to.

Thanks very much for the input, everyone! I'll try shellac and a thicker layer of polyurethane this weekend, and hopefully have good news to report! I'll keep my eye out for some poplar as well, and keep the epoxy trick in my back pocket.

To answer your question Eideann, I'm in Southampton, PA, and looking to avoid paying a foolish amount for wood.

Most any lumber yard or big box store will have poplar. It isn't rare at all. Takes paint far better than pine and machines cleaner, too.

However if used outdoors seal it very well. Bare poplar does not hold up to the weather at all, especially like where you are with a fair amount of rain and probably snow.

Mike

I would think that you should have a fair amount of hardwood dealers in that area. Do a google search and see what you can find. Poplar should be relatively cheap /bf from a dealer. Probably similar to select pine at a bigbox store price wise.

Best of luck

This forum post is now archived. Commenting has been disabled