Improvements to Kreg KMS7200 Bandsaw Fence

The Kreg KMS7200 bandsaw fence is well made with sturdy extrusions. I did find it necessary to implement some improvements, which I will explain here with photos. Also made a YouTube video of the improvements: https://youtu.be/paP43zCZfno

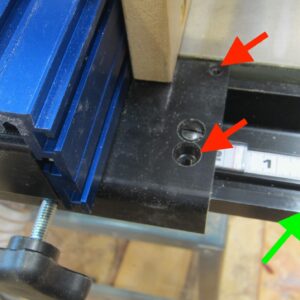

Photo 1: Did not install the 4 nylon screws (red arrows). Added a strip of UHMW tape along the rail (green arrow). To set aluminum fence perpendicular to table, I adjusted with the mounting bolts that secure the Kreg rail to the cast table – this seems more durable that relying on the loose fitting nylon screws to take care of levelling.

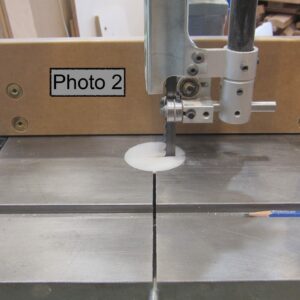

Photo 2: Made fence plates from 3/4” MDF. Secured them to aluminum fence extrusion with 1/4-20 x 1/2” hex head bolts and furniture connectors. The furniture connectors are set into shallow forstner drilled holes, so that they do not project out. Placed washers between the MDF and the aluminum fence to prevent warping. Waxed the MDF to make it slippery. Made a high fence for resaw and regular fence for other work. Calibrated and applied the ruler scale with the MDF fence attached. All fences are made from the same 3/4” MDF so ruler scale does not need to be recalibrated when changing fences.

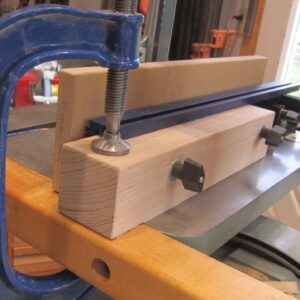

Photo 3: Secured a square block of wood behind the fence use 1/4-20 hex head bolts and wing nuts. The block of wood serves 3 purposes:

- Block rides along the wooden strip that is bolted to the edge of table, so that the aluminum fence does not scrape on table and is held a consistent spacing above table. Applied UHMW tape to the bottom of the block where it rides on the wooden strip. The Kreg fence slides smoothly.

- With block clamped to the wooden strip, I can push hard on the fence without deflecting it. Without clamp the fence can easily deflect 0.015”

- With block clamped to the wooden strip, the fence is kept perpendicular to the table because the block is square.

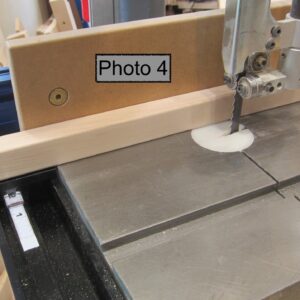

Photo 4: Made a little fence that can be hooked on, and just rests on the table. This allows the guide bar to be lowered for small pieces, without changing the MDF fence. The little hook fence is exactly 1” wide, so the measuring tape is still useful, just off by 1”

I set up the bandsaw following first half of Alex Snodgrass video, so the fence is simply aligned with the miter slot. No drift adjustment required when using Snodgrass method. https://www.youtube.com/watch?v=wGbZqWac0jU&t=0s

Replies

A handy way to prevent deflection is to just pop a Mag-jig magnet against the back side of the fence near the end--either embedded in a block of wood or not. It's super fast to install/remove/adjust, and it's plenty of force to counteract even very strong pushing forces.

I like the 1" fence--a simple and handy take on the 2 position fence that's part of some of the better factory and after-market fences. I love that it's deployable with essentially zero fuss.

This forum post is now archived. Commenting has been disabled