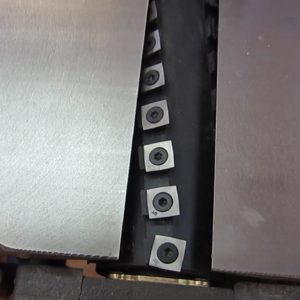

Makita 2020 Jointer upgraded with Byrd Shelix helical segmented cutter head

Upgraded my old Makita 2020 jointer with a Byrd Shelix head. I think this is the first Makita 2020 to be upgraded as neither Byrd nor anyone else had ever made a cutter head for this machine.

Here is a YouTube video of the upgrade:

Here is a folder with upgrade guide in PDF format, and additional information on Makita 2020 including instruction book and parts list:

https://drive.google.com/drive/folders/1w6LvL5J_PgqRbsTYaWZPupTGUERwunWy

In the past, I took the Makita straight blades to a good sharpening shop that returned them with cutting edge ground dead straight, but that shop went out of business in the 2009 recession, and I have not been able to find another shop that will grind straight. I tried sharpening the blades with a Makita 9820-2 grinder. Easy to get them sharp, but took considerable effort to get them straight to within 0.001 inch, which is just barely acceptable. My enjoyment of woodworking was declining because too much effort and stress was going into sharpening. That was my main motivation for switching to a segmented cutter head but I found other advantages as well.

I really like using the jointer with Shelix head. I took the time to get the head perfectly parallel to the outfeed table. This required placing 0.001 inch brass shim-stock under two bolts as shown in video. Now it will stay parallel, no more fiddling with straight blades. Results are now very consistent.

Snipe is almost non-existent because I can set the outfeed table very close to the cutting edge. Tear-out is rare, even when a board is planed against the grain, which is sometimes necessary when grain changes direction over length of board. Even though I wear ear protection, I can notice the machine is quieter and does not have that screaming sound that comes with straight blades. When a blade gets nicked, I just have to rotate one or two cutters and back to work with no further adjustments. Compare that with the heartbreak of nicked straight blades that require grinding, sharpening, and setting to get back in business. And one more thing: the Shelix head cutting length is 8.1 inch, which enables proper rabbiting which was not possible with the 8 inch straight blades, because they did not project beyond the table.

The Makita 2020 has a 120V 12A series motor. Changing to a 2 HP induction motor would be a good improvement, and I will make this upgrade if the Makita motor ever burns out. I have been running some 7 inch wide hard white maple over the jointer, taking 0.01 inch cuts, and the Makita motor does OK. I tried a 0.02 cut and had to go a little slower but sill acceptable. With a 0.04 cut had to go quite slow to keep the motor speed up so did not feel right. When jointing the edge of a board I can take off as much as I want without slowing down the feed rate. Some people have reported that they have to feed slower with a segmented cutter head but I don’t notice the difference.

Cost of upgrading Makita 2020 was about 1/4 the cost of buying a Powermatic 60HH with Shelix head. These machines are comparable in table length, and they both use parallelogram table height adjustment. The Powermatic is a heavier machine and has a more powerful motor. Aside from cost, another reason I decided to upgrade the Makita rather then buying a Powermatic is that I have a medium size shop and often have to move machines around to work with longer materials. Also, I have a wooden floor supported by floor joists, so don’t want to take a chance with really heavy machines.

This post is archived.