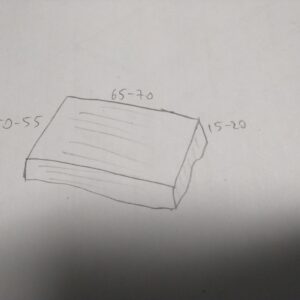

I’m building a floating vanity countertop out of a large walnut slab. It’s about 6cm thick.

It’s wide and long enough that I can rip it on the front (facing the user) and on one end (the floating end, on the right) to give the top an apron.

I want to do that for esthetic purposes, so that it feels more like a tree and less like a shelf. And to hide the pipes under the sink a little. Therefore the mating edges will be mitered.

While I don’t need the aprons to support anything except themselves – the joints do need to deal with possible bowing/twisting of the top. The slab is completely dry (9%) but who knows what tensions will release once I cut it.

Originally I was thinking of a simple miter joint. Though “simple” is just a word when it comes to something this massive. And on the right (see drawing) it’s going to attach end-grain-to-end-grain, which given the weight and the fact that it’s floating will probably not hold.

So I thought – is it possible to combine the simple miter joint with a finger/box joint to get both the looks and the strength I want?

I made box joints very successfully using the method I learned on FineWoodworking (see Ed Pirnik video). But I don’t know if that will work if I have to hold one of the VERY heavy pieces at 45% while pushing a sled. In fact now that I wrote that – I think that’s unrealistic.

What do you think? Do you have any suggestions for a better solution?

Thanks in advance.

Replies

Cut your miters on the table saw with the blade at 45 deg (work piece laying flat). Then put a spline down the center of the miter for strength and alignment. You can also cut the spline groove on the table saw with the blade at 45 deg.

Yours is the best way I know of as well. Since 6cm is about 2⅜", I'd suggest the spline be off-centered 1/3 from the inner edge to allow for a wider spline and also use a thicker than "Normal" hardwood spline for added strength as well.

Sounds great, thank you! I should have known I'm overcomplicating it :)

By the way - this is about 3 times larger than the capacity of my 12" SCMS. So I'll be cutting it on the table saw. Good thing I have a 14" Wadkin Bursgreen cast iron monster. That will handle it.

I just have to find a way to guide the cut to keep the cut straight. So far the best I came up with is an initial cut with a circular saw to establish two straight edges, followed by a handsaw and handlpane (my Skilsaw won't cut that deep).

Although I confess to not feeling like I have a clear picture of your problem. If you need to rip a straight edge on board without a true edge to guide against the fence, and don't have a jointer or bandsaw, just make a tablesaw jointer jig. Essentially all it is is a sheet of plywood large enough to extend beyond the workpiece 4-6" with some type of hold down clamp to hold the workpiece secure. If you are concerned about losing depth of cut the plywood can as thin as ¼" with a thicker board attached on the fence side to secure the clamps to and provide a guide edge against the fence. Simply clamp the the workpiece in and let the plywood edge ride along the fence. If you search FW or YouTube you will see how simple it is.

Look up how to make and use an "L" fence for your table saw. Go to the "How-To" section here on FineWoodworking and search for "L Fence". It is perfect for your situation. You use it with a straight edge guide on the work piece to enable cutting a straight edge. Actually, you can cut the miter at the same time you straighten the edge with the "L" fence.

esch5995' method also works.

I will add that if I'm picturing what you are trying to accomplish correctly, you can also reinforce the miter joint with a 1"x 1" cleat screwed into the apron and top in addition to the Spline or Domino's if you are so equipped. Wood movement would be minimal close to the edge but if you are concerned drill oversized holes and use washer head screws like those used to attach drawer faces.

My first instinct is a spline, a stopped spline if the ends will show. You could also:

- dowel

- domino

- floating tenons with a router

You may be over thinking this. I tend to do this . . . according to their posts many woodworkers do this. We're that way. Keep it basic and reliable; it's hidden.

I have a couple of ideas for you...

First, after you cut the slab up, best practice is to let the boards do what they will do and re-mill if needed to get to stable lumber. Instead of building to withstand potential stresses engineer the stresses out in advance.

Second, your design completely hides the fact that you are working with a thick slab, so to me you are wasting the "slabness" of the board on this project. If you resaw to 3cm (or even thinner) you'll have plenty of beef to execute your project at about 5/4 and enough leftover lumber for another whole project. Build the floating part in place and then add your walnut tree-looking box over it. It will look the same no matter how thick it is.

Third, for putting together the mitered edges and corner I suggest first a lock-miter bit in a router table. My second choice would be the festool domino. Third and down would be any spline / bisquit / screw & plug combo you like.

If you want to use cool joinery for what is effectively just an awesome countertop then the secret hidden dovetail would be first choice (invisible and completely unexplainable but a nice followup when you are telling someone how thick the boards are) and half-blind dovetails second. Box joints would be a bit clunky looking but very strong for the end grain connection and you could always miter the outside corner pin to make the front edge prettier.

Post a pic when it's done!

Thanks for all the suggestions!

I've definitely got to make that tablesaw jointer jig. I have a small one, but I almost never use it because it takes too much work to move the toggle clamps to a height matching what I'm cutting.

Maybe my measurements are confusing to you guys, I use cetimeters. This slab is about 2.5 by 3 boots in size. I'm not going to resaw or remill it :)

It makes sense that I don't need anything this thick, but noone mills such large slabs thinner than what I have. And frankly I'll enjoy the bulk even if it's mostly hidden. I find that when I make something I truly want and like - it still almost takes my breath away years later.

“[Deleted]”

This forum post is now archived. Commenting has been disabled