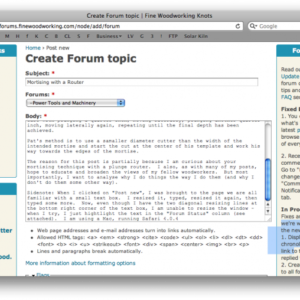

Typically, when I rout a mortise, I use a router bit the same diameter as the mortise is wide. I set up a fence and the depth stop on my plunge router and layout the mortise. I then make a series of full-depth plunges along the length of the mortise before cleaning up by guiding the router along the length of the mortise. Now, I’ve been reading through back issues of Woodwork and in issue #9 from 1991, Pat Warner has an article on Router Template Mortising. In it, he states that “Single-cutter witdth cutting is high-demand routing that puts undue flex into the cuter and dulls it early from heat build-up. Often the stress on the cutter is such that its deflection produces a mortise wider than the diameter of the cutter.” I’m not sure, but I think that is moreso the case with plunging a quarter inch, moving laterally, plunging another quarter inch, moving laterally again, repeating until the final depth has been achieved. Pat’s method is to use a samaller diameter cutter than the width of the intended mortise and start the cut at the center of his template and work his way towards the edges of the mortise. Edit: Pat Warner (routerman), I trust you’ll find this post. I’m curious whether your mortising procedures have changed since the article was published nearly 20 years ago. I haven’t read much of your work before delving into Woodwork’s back issues and am enjoying your articles very much. The reason for this post is partially because I am curious about your mortising technique with a plunge router. I also, as with many of my posts, hope to educate and broaden the views of my fellow woodworkers. But most importantly, I want to analyse why I do things the way I do them (and why I don’t do them some other way). Sidenote: When I clicked on “Post new”, I was brought to the page we are all familiar with a small text box. I resized it, typed, resized it again, then typed some more. Now, even though I have the two diagonal resizing lines at the bottom right corner of the text box, I am unable to resize the window – when I try, I just hightlight the text in the “Forum Status” column (see attached). I am using a Mac, running Safari 4.0.4 Note while editing: When I came back to edit this post, I was able to resize the text box once, and once only.

Discussion Forum

Get It All!

UNLIMITED Membership is like taking a master class in woodworking for less than $10 a month.

Start Your Free TrialCategories

Discussion Forum

Digital Plans Library

Member exclusive! – Plans for everyone – from beginners to experts – right at your fingertips.

Highlights

-

Shape Your Skills

when you sign up for our emails

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. -

Shop Talk Live Podcast

Shop Talk Live Podcast -

Our favorite articles and videos

Our favorite articles and videos -

E-Learning Courses from Fine Woodworking

-

-

Fine Woodworking New England Event

Fine Woodworking New England Event -

Replies

Chris,

You bring up a point that has long troubled me about both router-made and slot mortiser-made mortising. I was always hesitant to speak out about this, as I thought my technique might be faulty. But the problem I always ran into, especially with router-made mortises (using, like you, a bit the diameter of the mortise width I wanted to make) is that the mortise wound up being bell-shaped. It always turned out to be wider at the top than at the bottom.

That made fitting a loose (or any other kind of) tenon into the mortise problematic. In order for the tenon to even fit at the bottom of the mortise it would have to either be pared down to be too loose at the top, or made into a tapered shape.

I suspect that making repeated passes with the router, removing 3/16ths or so at each new depth, was the cause of the problem, or at least had something to do with it. Maybe the bit was able to flex a little when it was relatively unsupported at the top of the mortise, but gained stability when it was surrounded by the already-cut mortise walls as it neared the bottom. Whatever the case, I could never make this right no matter what I did.

Now I own a Domino and don't run into that problem anymore. But I'd still like to know what caused this issue.

Zolton

Chris ,

I would say in general it may depend on how deep you are going with the mortise. I use routers also and have not had the problem with shallower holes. For much of my work a 1/2" is adequate .I usually take two passes . I also use a 1/4" X 1/2" slot cutting router bit like up post legs to accept panels or frames as well as frame members .

How deep are your mortices ? Do they need to be that deep ?At a certain point we gain no integrity from the length of the tenon depending on the application .

regards dusty

Dusty,

Good questions: my mortises are usually 1"-2-1/2" deep, depending on project, of course. Most of my work involves larger-scale joinery, sometimes for decorative effect, other times not. My average mortise is maybe 1-1/2" deep. Do they need to be that deep? I don't know, but until I start weakening the mortised piece, it can't hurt, strength-wise. Build it to last.

Chris

I have 2 comments. One to your thread, and one to my pal Dusty.

Using a smaller diameter router bit to make mortises is an awful waste of time, especially if you're making a piece of furniture, or set of chairs, with 50 or more mortises. Using a router is slow enough, 3/16" deep per pass without having to go back and forth, also. A good quality router bit just isn't that expensive, compared to the added extra time for doing it that way. If you have a good router jig set up, it should just simply be a matter of swapping out furniture pieces in proper alignment, and getting the job done quickly.

As far as depth of mortise goes, I always go as deep as possible. For chair legs, where strength is critical, especially where the side rail meets the rear leg, you want at least 1" of depth, and preferably 1 1/4" coming from each side. Even if the two mortises meet in the back, and you need to miter them, the joint will be much stronger than having a shallow mortise and tenon.

Jeff

Edit: Oh yeah! The router bits that Highland Woodworking sells for the multi-router are excellent quality bits that last a long, long time. They are hss, and are spiraled down, so there is no tearout. I really like them and use them exclusively for routing mortises. And, they are not expensive. I never experienced the need to get the carbide bits for this, as I never, ever felt that the cost of the bit played into the equation at the end of a project. Try one!

Jeff,

Very sensible - especially the use of a spiral bit as this seems to even out the cutting forces so that there is none of that "bottom-belling" that Chris mentions. Solid carbide bits are also very stiff and seem to last a long time.

However, shurely shome mishtake concerning the spiral direction....? I use upcut, as this spits the dust and chips up into the router's dust collection shroud where the vacuum sucks it all away. No clogging up the bottom of the 'ole.

I do have a downcut spiral bit for cutting the channels for stringing, which channels must have clean edges hence the downcut. If I mistakenly use it to dig a deeper hole, the chips are forced down and soon clog up the whole shebang.

I always router-cut a mortise from the side that will have the tenon-part abutting it. Any slight raggy edge from the upcut spiral is thus hidden (although a spiral doesn't seem to leave much rag, compared to an ordinary two-knife straight bit).

Also, one can plunge a through mortise with an upcut spiral as the breakthrough doesn't cause edge-rag at the emergent-end. The upcutting spiral makes a very clean edge as long as one does not plunge madly.

Lataxe

Jeff,

I also thought that a narrower bit was a bit of a time-waster, but if it does a better job, I'm all for it. How are down-spiral bits to use? I've never used one, but from what I understand, they don't eject chips (the trade-off for no tearout). Does it push the router up at all?

PS: Elite Tools out of Quebec offers a set of 5 up-spiral carbide bits, 1/4-1/2" for $100. I ordered a set and am really happy with them.

Chris

Yes....downcut spiral. With a router, you just can't hog that much material out in one pass. The router bit lets you know what the limit is by the noise it makes. When it's cutting well, it has a nice sound. When it starts to scream at you, you know you're hogging the wood out, and chances are, you're gonna mess up the mortise.

Lataxe......with a downcut spiral bit, you are pushing the chips down, but since you're not hogging 1/2" to 1" at a time, it doesn't matter. I use a shop vac connected to my router whenever I am routing, and it does a fine enough job of clearing the way when mortising. I'm only plunging 3/16" (approx.) at a pass, anyway, so there aren't any real big chips. I have a mortising jig which I have shown here on occasion in the past that I slide the router on, back and forth, which holds the router in a track. I made it out of scrap, but can't show a picture of it as this new website is horrible.

Yes, I saw the thread on web hosting using Photobucket. Sorry.....I refuse to go through all that. It's the pig-headed Scottish-Irish-Italian in me. The danged administrators of this site should fix that, and alot of other things, toooooooooo, before everyone goes away for good. I'm getting sick of this.....

Wah, wah wah wah wah.......

Jeff

At some point way back in time, I read in an article in FWW where the author said the router is essentially a trimming tool and is really lousy for hogging wood. I agree with this and adjust all my operations accordingly. If this means it takes a bit longer to cut some mortices, so be it. At least I know that I'm doing what I can to assure their accuracy. And, I know its still not taking nearly as long as chiseling them out by hand.

I use a Mortise Pal jig for routing mortises. The jig relies on templates designed for a single-size collet. The bit used determines the mortise size.

The jig achieves smooth-walled mortises because the template is cut 1/64-inch wider than the collet. The recommended technique is to plunge-cut a series of overlapping holes for the length of the template, then cutting around the periphery of the template for a finish pass. That extra 1/64-inch cleans up any scalloping caused by bit deflection during plunge cuts.

Donald,

Thanks for the comment. I was looking at the Mortise Pal along with the Woodrat and FMT a while back. I decided on none of the above... for now.

Same music, essentially the same theme. Use a narrow cutter, let it waste 90% of the excavation in width. Then on your last circumnavigation/pass/depth of cut, let the cutter trim what's left.

http://patwarner.com/router_morticing.html

*******************************************************

As such, the cutter is hardly stressed as the router hits its stops. I'm talkin' the final waste/pass of ~1/16 or less, hardly enough to bend the skinniest of cutters.

***************************************************

Want a tapered mortice? Then waste a diameter wide mortice with an up-spiral. The skinny ones bend like crazy, most of the thicker ones (slow, fast spirals, up/down compression etc)don't cut straight walls. Straight solid or brazed-on carbide bits cut very straight walls if you treat them with respect. Respect = waste speeds = cutting rates. If the cutter is screaming you will booger the mortice.

Pat,

Good to hear that you're

Pat,

Good to hear that you're still using the same technique. Do you think a solid carbide up-spiral bit can cut non-tapered mortises if used with your 90% and clean up method?

Haven't seen much evidence of

Haven't seen much evidence of it.

.50" (solid carbide) cutters with slo-spirals are plenty stout enough but since their cut profiles are not straight the walls of mortices are often tapered or otherwise mishapen.

Skinny bits? Count on a taper independent of method.

Can't prove this but I think these cork screw bits unwind slightly, accounting for some of this bizarre wall geometry.

For the casual user I suspect this will go unnoticed.

This forum post is now archived. Commenting has been disabled