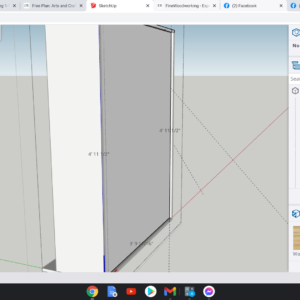

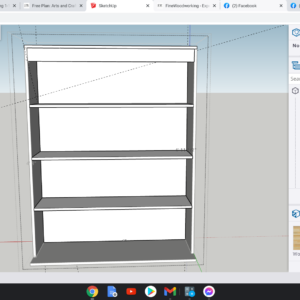

Good evening all. I’m a novice woodworker, but good with my hands. I’m also a quick learn. I just finished building my workshop(concrete, framing, drywall, painting, assembly all me) and I have my first assignment: build my sister a set of 2 built-in bookcases and install them. I have attached a very basic first draft of what I want to create. My idea is to use 1/2″ Birch plywood for the base, top, sides and rear. My brother-in-law explicitly decided to use pine for the shelving so I’ll be using 1×12 primed pine for the shelves. I want to build the case so that the back is attached 3/4″ into the case frame with glue and 1″ – 1 1/2″ brads. The reason for the 3/4″ recess is to allow for a piece of 3/4″ brace(approximately 3 per case) attached to the case and attached to the wall at stud points. Each case is approx 48″ wide, so I should hit at least 2 studs. All of this to say, am I on the right track? Specifically, please help with the following:

1. Is 1/2 Birch plywood strong enough for a case this size?

2. Will my method of fastening to the wall be secure enough to support the wall?

3. Nails or screws to fasten the case together?

All HELP will be appreciated. Thanks in advance

Discussion Forum

Get It All!

UNLIMITED Membership is like taking a master class in woodworking for less than $10 a month.

Start Your Free TrialCategories

Discussion Forum

Digital Plans Library

Member exclusive! – Plans for everyone – from beginners to experts – right at your fingertips.

Highlights

-

Shape Your Skills

when you sign up for our emails

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. -

Shop Talk Live Podcast

Shop Talk Live Podcast -

Our favorite articles and videos

Our favorite articles and videos -

E-Learning Courses from Fine Woodworking

-

-

Fine Woodworking New England Event

Fine Woodworking New England Event -

Replies

1. Depends on how are you planning to fix the shelves. If the shelves will be fixed permanently it will be okay, if they're adjustable you might want to make sure fronts of the sides are either rigidly attached to something or reinforced in some other way, like a small face frame or something. Making one middle shelf permanently fastened would work too. The sides would want to cup outward, but other than that 1/2" is plenty strong.

2. Assuming the back panel is properly glued and fastened it should be sufficient.

3. Depends on whether you think it will ever be disassembled. A glued plywood joint is very strong, you're not gaining anything in terms of strength by adding screws, and brad nails serve as clamps mostly.

You might want to talk to your in-laws about the shelves. At this span 3/4" pine might sag under load eventually, books are heavy. Two asymmetrical vertical dividers between a pair of shelves would solve this problem and add some visual interest. Also, if these shelves are standing on the floor, I would add a kicker (like the piece you have at the top). Other than that the sketch looks nice.

Thanks for the advice. I'm going to take the advice many have offered here to use 3/4" board. The advice on the glue and on board span also helps. For glue, I'm leaning towards Titebond 3. You have a preference?

Back when I started, there was only Titebond original. It's always worked perfectly, and I've never had a glue joint fail.

When Titebond 2 came out, I naturally thought it was better, so started using it. The only difference I could perceive was it was fairly waterproof. Doing glue ups, I would wipe excess glue on my shirt, to avoid contaminating the wood.

Titebond Original always came out in the wash. Titebond 2 didn't. After getting enough glue on a shirt, I could take it off and stand it up in the corner. But it added nothing to the quality of my woodwork.

Titebond 3 is even more waterproof. It's a quality that I don't need, at all. I have zero reason to waterproof joints. But I do like clean clothes. So, I only use Titebond original when I use yellow glue.

Though, for most things I use Old Brown Glue.

Will this be hanging on the wall, or sitting on the floor and anchored to the wall?

I'm assuming this is sitting on the floor. I'd make the back 1/4 inch. Rabbet it into the case enough to make it flush, and you can put a couple of screws into the wall to keep it from tipping.

1/2 inch is too thin for the case. Definitely use 3/4.

Is this bookcase holding books, or anything else heavy? If it is, almost 4 feet wide is way too much for pine or plywood shelves. They will sag really badly, and more over time. Consider a central divider, or add 1-1/2 or 2" vertical strips to the front and back of each shelf.

Thanks for the advice John. It'll be hanging. I'll definitely use the 3/4 board and support the shelving with the central divider

I'll echo the ¾" plywood it won't add much to the cost and is preferred for a number of reasons. The 48" span is going to require some sort of additional bracing in the form of either an additional vertical member or additional strongback support approximately 1½"x the shelf width as John_C2 mentioned. The rule of thumb is maximum width for shelves is 36" and 30" is better if heavy loads are anticipated.

When you mention your brother-in-law wants to use 1" x 12 primed pine" I hope you aren't referring to the crap the home centers sell. That stuff is preprimed for a reason, to hide the fact that it is garbage wood. You would be better served using the plywood. Speaking of plywood, if you are buying poplar core plywood, especially from the big box home center, particularly one who likes the color orange, beware and scan each sheet carefully for flaws. I've long ago stopped even trying to find usable sheets there, the couple extra dollars it costs to get quality voidless veneer core plywood from a local hardwood dealer is made up for in time saved shifting through heavy sheets of trash to find a few usable boards and the frustration that ensue.

As for attaching it to the wall your method is sound enough, but the ¾" recess isn't really necessary if the cases are truly"built-in" with walls on both sides. I would simply screw a 1"x3"s horizontally across the wall the screw my case to these. A more advanced method of attachment is to screw through the sidewalls where the screws are much less obvious but that takes more pre-planning to ensure proper anchoring.

I would absolutely go with plywood shelves with wider solid wood strongbacks too. Especially if the plywood is actual Baltic birch. The preprimed pine is absolutely not an upgrade.

It doesn't sound like it's truly "built-in" but rather a bookcase being placed into an alcove. It would therefore be better to leave it free-standing but in the fashion advisable for all bookcases, with the feet made to cause a little bit of lean-back towards the wall against which it stands. (The rear wall of the alcove, in this case).

Free standing means it can easily be moved to somewhere else, if & when events suggest it.

Plywood shelves will also tend to sag - more so than many solid hardwoods for the same thickness - so they should be lipped (back as well as front, really) as another poster suggests; which will also hide the fact that they're plywood.

What will be the joinery between the sides and the shelf ends? This can be a source of problems when the shelves are long so might sag, especially if the joint is a simple dado and nothing else.

Sliding dovetails in plywood? It is possible as I've done it. The plywood needs to be high quality. though (I used Baltic Birch). It needs to cut like solid wood rather than like flake board. :-)

Lataxe

Just to add one other note. If you are going to prefab this then installing onsite, check the floor for level in both directions and walls for plumb.

I echo a number of these concerns: re the materials being used, re the sag in a 4' shelf. With regards to installation you could think about attaching a french cleat to the wall and it's counterpart on the top of the book shelf

Thanks to everyone for the advice. Greatly appreciated. Gonna hit the drawing board again taking all of the excellent feedback which was provided and I feel very confident I'll be able to present a great offering to my brother-in-law and sister. Looking forward to growing much

This forum post is now archived. Commenting has been disabled