Hello everyone!

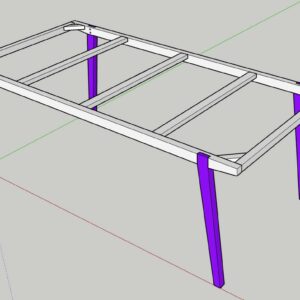

My name is Lili, I am amateur in this topic, ive made some basic pieces (shelf, chair, cabinet doors) and have been working for a while in designing a table for my dining room. I’ve done a digital model of it already (pictures attached), now i am trying to decide on the best way to join the pieces.

I’ve attached an image of what i have in my head right now, I am considering on doing a half-lap to attach the aprons to the legs, if this seems right, what would be the best way to secure them? I was thinking of inserts and bolts. The corner piece i’d secure with pocket holes. I am worried about wood movements, so if there is a better way to do this, please by all means, i will gladly take any advise.

I know its a big project, and thats why i came here for help.

Thanks in advance.

L.

Replies

Hi Lily, a couple thoughts:

1. It's a bit hard to tell from your picture if this is already part of your design, but you'll want to notch the leg so that the apron sits on that shoulder.

2. To attach the legs to the apron, I would do threaded inserts.

3. I don't think your corner brackets are large enough to create and concerns about wood movement.

4. The top is where you will want to accommodate for wood movement. The rule of thumb is expect 1/8" of movement per foot of width.

Hi! Thanks so much for your reply :)

Yes sorry i missed that image, i attached it now, would that work? Is that what you mean?

Should corner brackets be larger then?

For the top, are z fasteners okay or would you do figure 8 fasteners?

Thanks again!

Nice project. I’d consider widening the aprons to give more strength to leg joint; and making the tabletop wider and longer than the base so seasonal wood movement won’t show.

Thank you!

I did widened the aprons and stretchers, they are both 2" now, so the shoulder is 1 full inch, do you think that's enough or should i make it even wider?

How much would you add to each side of the table top?

The tabletop ‘lip’ should go all the way around the apron, not just on the sides. I’d start with 1” to 2” and see how looks in digital. If that makes the top too big for the dining room, then reduce the apron dimensions.

Without any other support, the legs are going to need special attention to prevent wiggle and joint failure. Hopefully you are are planning to use a hardwood like maple, oak, or walnut. The legs should be thick like 6/4 and, yes, use a lap joint with recesses in both the legs and apron. These should be tight fitting as this is what will keep the legs rigid. Don't rely on the just the bolts to hold them or the joint will surely fail. Unless you want/need the legs to be removable, tight fitting joints, maybe a couple of dowels, and glue will be the strongest

Side forces on the legs will tend to make the apron twist. So, put another cross piece at or near to the leg joints and make them nearly as wide as the apron. Set all of the cross pieces on edge with mortise and tenon or doweled joints. This will keep the aprons stiff.

Jamenard is correct that seasonal movement it not a concern with the leg and apron construction, but certainly is with the top. Just fasten it down with "Z" clips, figure "8s" or slip blocks and you should be OK. Of course, do not glue the top to the apron or cross pieces. Keep in mind, of course, that the movement of concern will be cross grain.

There are web sites that will help you calculate seasonal movement based on wood species and temp/humidity changes. Just google "wood movement".

I really appreciate your comment! I was planning on maple or white oak, i would have loved walnut but its a bit out of the budget!

I attach an image of what i was thinking for the lap. The width of the apron and legs would be 2" each, so the shoulder and recess would be 1".

Noted on the mortise and tenon and also added the extra cross pieces to hold down where the legs and aprons join.

Thanks a lot!

Just so we are talking about the same thing, I assume when you say "width" you are talking about the horizontal dimension as you show it. To me, that would be thickness (LxWxT in order of diminishing size). What are you planning on the vertical dimension (width) of the apron to be? I don't think it should be less than 4" and best if it were more. Again, this goes to stiffness needed without further leg bracing.

Hi Lilli, I think your leg joints will eventually fail for a few reasons.

First, the metal threaded inserts WILL eventually loosten due to wood movement. The wood will expand and contract, compressing itself around the metal parts. Eventually it will lose elasticity and get gappy when it expands. This is common on wood screws and will leave your legs loose.

Second, you are depending on a lap joint that will not resist the lateral force of someone just leaning/sitting on the edge of the table. The racking forces up high will be huge and in my estimation will just rip out the inserts. This would be easy to test on scrap at your bench.

Third (and this is speculative), the joints at the corners of the table look to be butt joints. If the leg joints don't fail with the lean/sit activity the corners surely will; even with a dowel or two in there. Traditional apron'd table construction uses beefy M&Ts at the corners for exactly this reason. The angled corner blocks will not save it from the racking forces. Turning the cross-braces to the vertical instead of the flat will help a little.

I agree with ElMaduro that the table should extend beyond the base for both the wood movement aspect and the eventual liquid spills. If you shrink the apron footprint a stretcher M&T'd between the sets of legs would add stability, but would not prevent the eventual failure of the threaded inserts.

SO... what I would suggest is a redesign of that joint to a "vertical dovetailed half-lap". It's been used forever in workbench construction and resists racking. For a starting point in your joint design use the LAUNCH GALLERY button at the link below to scroll through some photos:

https://www.finewoodworking.com/2012/09/18/antique-workbench-transformation

A bridle joint at the same spot would also be stronger (you need to scroll down a bit):

https://www.finewoodworking.com/project-guides/tables-and-desks/federal-demilune-card-table

Since you are biting off a "stretch" project I think this is well within your range. GOOD LUCK!!

MJ -

What are your thought on using epoxy to hold the metal inserts in place?

No diff, the epoxy would be a thin coat on the threads and also non-compressable.

Respectfully disagreeing on the metal insert, they will not loosen with wood movement, just like a screw does not. The cross grain half lap joint you show could be strengthened as said above by widening the apron or by having more apron side support such as adding triangles to join the top to apron to keep it from flexing when the table is pushed sideways.

Circling back here on the overall design and will offer most tables are all constructed the same way. The base is classic mortise and tenon joinery between the legs and aprons to give maximum structural strength and longevity. The top always overlaps the base to hide wood movement and give the table a pleasing-to-the eye dimension. Once the top is securely attached (with allowance for movement), the table becomes structurally strong and the aprons will keep the top flat.

With this being your first table, I would consider designing and building a more classic style.

This forum post is now archived. Commenting has been disabled