Please help!

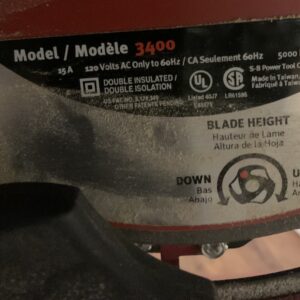

I just picked up a used Skilsaw 3400 but it unfortunately did not come with its splitter/riving knife assembly. I have looked all over the internet for this part (Bosh 2610358814) but have discovered that it has been discontinued. I really want to be able to use this saw safely so I’m wondering if anyone has this part, a way of sourcing it, or suggestions for alternative routes. Any help is appreciated!

Replies

I would say your best bet is a saved search on Ebay for the part number. That may be the best bet. Of hit up alot of flea markets in the spring.

Skil has undoubtedly offered a replacement tablesaw and it's possible that the new saw has a similar splitter arrangement or possibly the same. With that said most of the plastic portable saws guards and spliters are so badly designed that they make the saws almost impossible to use. The manfacturers have to supply safety features but it seems the designers just phone it in! I've never seen anyone leave those things on, including myself. Mine is a Delta, but I have had a skil, a craftsman, and a Makita and I've used various other brands. You can't just toss the 66 in the back of the truck so I always keep what I call a Tupperware saw. The upgraded plastic saws by Dewalt or Bosch are probably a bit better but the owners of those seem to deep six the guard arrangements as well. I've been on hundreds of job sites ,the carpenters have saws, the flooring guys have saws, the cabinet installers bring saws. I must have seen thousands of portable saw arrangements and never once saw one with their safety equipment still on the saw. It would seem probable that with all those saws out there that at least some owners threw that stuff in a box and not the trash can so you may find it someplace.

Matt Kenney did this review 2017;

https://www.finewoodworking.com/2017/07/25/ark-shark-guard-from-leeway-workshop

That does not look to be a challenging part to make.

https://www.amazon.com/Bosch-2610358814-Parts-Splitter/dp/B00Y9NODVQ has a nice picture that you could scale up.

I doubt it would be particularly expensive to have made at any fab shop with a CNC plasma cutter. The key dimensions should be easy to figure out. IFWY I'd get two done - one with a taller post so you can use more of the blade whilst still keeping the guard in place, and one for when you don't need so much blade exposed, or need it to come below the top of the blade for non-through operations.

While you are at it, you could get the guard holder slot machined to fit a guard you can easily obtain - the slot is not relevant to the function of the splitter save for being needed to hold the guard.

This forum post is now archived. Commenting has been disabled