Since the Knothead Think Tank worked so well on the heartpine issue, i will toss this new mystery wood your way:

This wood came to me as approx. 4″ x 4″ x12′ “posts”, for lack of a better term. I was given about 10 pcs. that had been stored without cover for some time, then under cover outdoors in British Columbia for a year or two, then i put them in my shop for a year. They were slightly checked when i got them and haven’t checked at all since. The wood does not float in water; it doesn’t even bob.

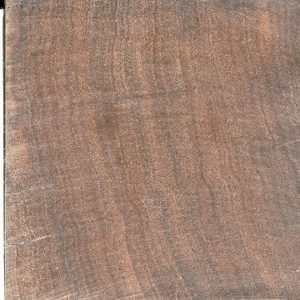

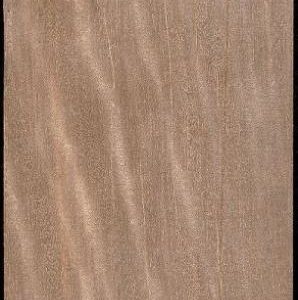

The flat grain has wavy checks about 1/4″ deep. The vertical grain has a roey appearance. The end grain pic (scale: 3.5″ x 3.5″) was cut with an 80-tooth miter saw blade only–looks glassy. The turned piece shows it turns well without chipping or splintering, but it blunts tools quickly, as might be expected.

I also haven’t got a clue what to do with it. Bowling pins? Cue balls? Chock blocks for tanks?

Replies

If you keep this up I'll have to go and get a more extensive reference manual.

It doesn't float, therefore SG>1. My reference really only gives one choice, after allowing that you would recognise some, and the colour of others is all wrong compared to your sample.

If it's a fine even-textured, heavy, lustrous wood, with dark heartwood which has an attractive variegated striped figure of violet-brown, black and golden yellow then it could be Dalbergia cearensis (Kingwood, Violet wood, Violetta) or a related species. Comes from South America. Average dried weight is given as 1200 kg/cu.m. It is described as relatively easy to work with sharp tools, and burnishing to a fine natural finish, polishes well with wax. Common uses inlay, turnery, marquetry.

After that I'm guessing a ecualypt, but only cause I live in Australia, see a lot of them, and know that some species don't float.

As to what to use it for - cribbage scoring pins ? :-)

..and eddie, Ostraya friends:

Not kingwood or lignum vitae, as i have some of both of those. The wood is an even-colored, dusky, dark lavender-no hint of sapwood or any other tones in these pieces. Not the purple tones of purpleheart, but very soft and muted heading to med. brown, and yet it doesn't register as "brown" at all.

We're now moving into the realms of speculation. Your material could be one of a number of Australian euculypts - the propensity to sink is the match and also surprised the English mightily when they first settled here. In my local library is a book containing extracts from a British Naval survey of timber in the Sydney area made in about 1800. The stand out comment about a lot of species is that the wood doesn't float - the implied tone is almost "it looks like wood, it cuts like wood, but it can't be wood - whoever heard of a wood that sinks". As to how an Aussie timber got to BC, not only have euculypts been planted all over, but there used to be a thriving whole log trade, mostly for wharf and warehouse construction. Sailing ships specialising in the whole log trade even had bow doors to make it easy to get long logs into the hold. Sigh, now days most exported timber goes out as wood chips and or whole logs bound for a chip mill.

I recall my first time smelling a stand of eucalypts on my way to the southern California coast--almost head-splitting at 100*F. I was told that they were planted by the pioneers in that area for furniture wood, but the wrong specie had been brought over and the grain was so twisted it could barely be sawm into firewood, let alone lumber.

I bought 50 BF of jarrah (E. marginata) to try last year, which means i have a new standard (formerly purpleheart and wenge) re difficulty to work and wear on tools.

Looks like either Eddie or I will ahve to send you samples of other Australian timbers. Well I recall a comment in the Workbench Book from a woodie who had built a bench out of eculypt "nice stable wood but it eats carbide router bits"

Ian,

either great minds think alike or fools never differ - I'm not sure which one I fit in.

Looks as though we were writing identical posts at identical times.

Twins?

Cheers,

eddie

Edited 1/18/2003 6:02:27 AM ET by eddie (aust)

This discussion tok off and you've already gotten around to what I would suggest. I think it is indeed Turpentine, if it's really an Australian wood - not a eucalypt at all. Turpentine, or Satinay (Syncarpia sp.), is the choice wood for wharf piles in Queensland, where most of it grows. Your side-grain shot is pretty convincing - the fine grain and oblique wavy figure running through it are classic. One of the reasons it makes a good wharf timber is that the silica content dulls the teeth of the little suckers which love to chew such delicacies, so it does do a number on edge tools. Pradoxically, it turns okay, and threads well with my router system - makes pretty durable clamp screws!

The other wood that came to mind when I saw the turned bit was Brush Box (Tristania spp.) but I changed that when I saw the other shots. As Jon points out, macro appearances of woods can be very misleading - there are an awful lot of lookalikes in the wood world! But if someone is going to take a serious look at it, Syncarpia would be my first bet.

As to what it's good for, Splintie - you got a very low jetty you want to build? My favourite use, apart from handscews, is cutting-boards - you won't wear them out in a hury, and they scurb up beautifully. I made one for myself quite a few years ago, and have had to make many more since, for folk who admired it so. I've run out of most of my supply, and don't think I'll get any more for a while - my source of supply (my dad) turns 88 shortly, and doesn't feel too thrilled about milling another log for me. I guess he has a point...........

Cheers from the other Ian.

---- from the third IanHaving had the opportunity to look at and work with the stuff, it's definitely not turpentine -- I've laid turpentine as flooring and the color of this isn't right.I'm sure Jon's on the money with his Ipe conclusion.IanDG

I've spent a couple of hours trying to find pictures of the lumber of all the species mentioned since i was here last--i couldn't find the ironwood, tingle, or turpentine except as living tree photos, which are so beautiful i didn't mind the detour.

Looking into Tabebuia, i found it described as "olor fuerte característico especialmente cuando está recién cortada". However, this has no special smell to report and not strong by any means even when recently sawn, and no taste, either. As a synonym for pau d'arco, it appears this is one tropical that might actually contribute to my health instead of kill me!

Jon, your sample was mailed a couple days before Eddie's bec the local PO had someone on duty who couldn't figure out how to send something overseas. Which reminds me, they said they would pay the postage and let me pay them back when i got home...life in a small, small town... <G>

Phill, wouldn't 4x4 be too small for railway sleepers--what i think we call "ties" here--that which supports the steel rail? Wouldn't there be spikes to hold the rail to the wood?

I tend to doubt this wood is recycled/"deconstructed" bec there are no holes or fastener marks at all and the unplaned surface was as it came from a saw, just silvered from exposure. I wonder, since the 4" dimension is tall enough to get forks under, if they might have been used as stickers under another load, perhaps under pallets or bunks of other lumber. The 12' length isn't what i'm used to seeing in warehouses, but i don't have any idea how ships are loaded; maybe they use long stickers. That would explain their apparent lack of worth (stored outside in the weather before they came to me) and that they have no fastener marks.

Ron, mulberry has a yellowish hue and isn't nearly as hard as my mystery wood...it floats!

So, without a definitive answer, i've still learned a bunch. Meanwhile, the increase in what i know nothing about is still manageable. I'm now considering turning this wood into the new kitchen come summer...with copper panels...mmmm....

floats ugh? well I don't know? foreign wood ya think? I have some stuff here that an old man told me they use it for bearings long ago in the submarines prop shafts to keep down noise. hard as nails & very heavy. any clue? do you think it floats ?

I know nothing about subs, but lignum vitae is used as a wood bearing, along with maple. Color would suggest it's a maple bearing, but the focus makes it hard to tell. These are still made by a company called Woodex out of Maine. The bit of reading i did suggested that only organic lubricants work well on them, like tallow and beeswax.

Is lignum vitae - horse apple-osage orange-bois d arc- hedge- all the same wood????? The pic was osage orange form the Ozarks.

Osage orange i wouldn't have guessed, since i have a bowl made of that and it doesn't seem that dense. Horse apples?? In local parlance, they are certainly not associated with lathe work. In any case, they come pre-rounded by the time we encounter them. <G>

Osage orange and bois d arc are the same. Lignum vitae is very different. The other two I can't speak for. All the samples of lignum vitae that I have seen are brown with olive stripes.

Hmmm, Eddie, I tried the alkaline test on Splintie's sample and it flunked. Sure looks like ipe, but if it is, I couldn't get the lapachol to convert...So, I'm back to square one. It could still be ipe and I'm just doing something wrong.

I don't want to fill this thread with a bunch of speculation. I'll e-mail you with some thoughts. There couldn't be more than a half dozen or so commercially important timbers with this color, texture and density.

...But I'll put just one last thought on the table. If it's not ipe, I think my next guess might be that it is balata (AKA; bulletwood, Manilkara bidentata.) I've confused these two before, since balata contains a latex that also causes it to develop a luster when hand rubbed...and it looks very much like some of the darker examples of ipe. It too has an air dried density that is several pounds per cubic foot heavier than water...so it's certainly no rubber duckie when it comes to floating...And it's commonly used for heavy construction.

I bought a board of figured bulletwood (fiddle-back curly--unless it all comes like that) from Myles Gilmer a few years ago and thought this might be the same, but i rejected it bec the bulletwood had an extremely bad tendency to warp. I'd wanted to use it as box tops bec of the curl, but whenever i acted like i even planned to raise a panel, it developed twist. The ? wood is rather stable by comparison. Without being able to really describe the smell, i thought the bulletwood had a faintly sweet odor, while this has next to none.

It occured to me to contact Gilmer to see if he might have some insight from his globe-trotting. I'll drop over there and email and see if he's willing.

Colleen, I have been away with work for a while and have not had a chance to look up recent discussions. As I was reading this one I thought that it is one of the most intriguing of the threads, reads like a detective story. I have no clue as to what the wood is but am interested in the process being followed to find out. Will keep reading....

Marcello

Hi, Marcello. I was away for a week, but noticed nothing posted from you when i got back. I thought it was bec you were involved with finishing that unusual vanity for your daugher... ;~)

Yes, this thread is interesting. I get lots of pieces of wood given to me to play with, but i have so much of this that i finally decided i should know something about it. I was thinking of using it for the frames for the new kitchen, but if it's that unstable, i'll shelve that idea. I'll have a lot of mortar and pestle stock, in that case--something for which i already know it's very suitable. Now to find a buyer for a few hundred of them!

Colleen, I'm still working on that vanity. I was detoured there for a few weeks to finish, or get started, on other projects. (Now I have more unfinished projects than I like to think is normal). My dad is showing some paintings on an art gallery in the hospital and I have been busy making some frames for him out of cherry and sycamore - hope to finish those today. This is deviating from the nature of this tread, I'll continue this elsewhere.

Good to hear from you.Marcello

Hi Colleen,

I finally got your answer.

This is poor man's lignum vitae, out of the Phillipines. Used in bearings, etc...

Mancono is the generic name

xanthostemon verdugonianus scientific name.

I'd hold on to it and find out it's value, now that lignum vitae is a rarity (if it's not too late).

Same family as brushbox and turpentine.

Cheers, eddie

I'll email you later today

Well sleuthed !

Forgot to give credit where credit's due here - Ian also gathered a fair few of the samples.

Cheers (again)

eddie

I got the family as Myrtaceae--correct? If it's worth anything like lignum, i'm RICH, i tell ya, RICH!

I'm still racking my brain over what to do with it if i can't find a higher-use buyer, but i'm thinking it would make killer pole bean supports...<VBG>

You have my email by now. I am really, really impressed with your stick-to-itiveness. Thank-you, Andrew; you're the best.

Sure looks like just some old Mulberry to me.

Splintie, you're right about balata / bulletwood not being very stable...but this sample you sent me has spent only one night resting on top of my work bench and it already looks like a roof tile...So, I wouldn't say balata is out of the running.

The more I look over the rim of my beer glass at that sample, the more I'm sure it's gotta be one of three woods; ipe, balata or ekki...but let's wait and see what Eddie comes up with.

Hi Colleen/Jon,

Sample sent to me has cupped 1/16 since I received it.

Have asked around, will let you know replies.

Cheers,

eddie

Edited 1/31/2003 9:29:49 PM ET by eddie (aust)

Roof tile, eh? Ok, after dinner, i'm off to the shop to cut a roof tile of my own, to rule out movement based on differing humidities in our shops.

Hi Colleen/Jon,

Another possibility.

If it's eucalypt and if it came from a wharf piling and if it blunts tools twice as quick as Jarrah, it's probably turpentine gum - used almost exclusively for wharf piles and flooring as it has this annoying habit of coating the inside of each cell with a nice, decay preventing, wear resistant layer of silica.

If you want, I'll send either of you a small sample - ping me with your address and I'll get a 75mm x 75 x 5 sample out.

cheers,

eddie

It doesn't look the right color for turpentine -- that's more of a BrushBox color -- in fact I used it as a substitute for BB when the supply of BB got too varied in color.IanDG

Hi Ian,

I don't know how well my monitor's transmitting colour so I threw the suggestion in anyway - I have approx 100ft of turpentine in my workshop and a floor in our main bedroom. The occasional board is close to the colour in the picture, but in the main, yes it does get close to brush box. Would you believe we used to use and throw away 12" x 6" x 60" dressed brushbox slabs/filtches when they used to cost USD2.50 each - talking late eighties here.

Cheers,

eddie

throw away 12" x 6" x 60" dressed brushbox slabs/filtches when they used to cost USD2.50 each

I worked briefly in a sawmill in the days of "teepee burners". They let me cart away anything < 8 feet in length. I remember this perfectly clear slab of sugar pine i could almost wrap my arms around, 8' long with a small corner broken off...it kept me in drawer sides a long, long time.

I'm dropping my street addy via the forum and would love to see a sample of the gum. The only other Australian wood i've worked is lacewood, or silky oak, at the other end of the hardness spectrum. Extremists, eh?

Thanks! Howz about a nice piece of tiger- or birdeye-maple in return?

G'day eddie,Yes, I sanded a T&G jarrah floor once in Toorak and the dumpster outside was FULL of offcuts. Now I'm back living in UK and reduced to particle board, pine and MDF -- enough to make you weep.

For Oz samples, how about Yellow Box or Grey Box if you can get them? -- any of the reds'd be good, Sydney Blue Gum or Forest Red Gum perhaps. Queensland Silver Ash would be unusual -- I don't suppose you could get hold of a bit of Johnson River, especially the almost black with a sulphur streak?Oz has so many magnificent timbers it's hard to know where to start.

IanDG

It looks like Ironbark (Euc.Sideroxylon) -- the heartwood of that is dense enough not to float and the color and checking is typical but I can't imagine it would be so far from home.

My best guess would be Ipe.

Best usage? -- caskets for people who want to be buried at sea.

Edited 1/17/2003 2:08:51 AM ET by IanDG

Another reply from this part of the world .

My thoughts were it may be a eucalypt - do you have a close-up picture of the grain texture? On another tangent, even though the colour and grain pattern aren't correct, isn't lignum vitae also waxy and has a density >1

Use: 100% organic sinkers for environmentally conscious fishermen

Cheers,

eddie

When they restored pier 17 in NYC, "The SouthStreet Seaport" about 20 yrs ago my Dad used to bring hunks of scrap home. It was I think the exact same wood. IPE.

PS

There was an article on IPE in FWW about 4-6 issues ago.

I thought i remembered an article (Jon, did you write that?), but a search i did on site yielded "1 of 0" (now, that's just odd...) and nothing in the window. I looked back through my mags, but it probably got misfiled. I'll do some housecleaning later today, see if i can find it.

Splintie, there's a chance it's ipe...but unless a wood has some very unique feature to it's anatomy that sticks out like a sore thumb, you really can't ID a species from a computer transmitted photo.

Another possibility is that it could be ekki; Lophira alata. This is an African timber that is exceptionally hard and heavy and it's used for decking and mine timbers all over the world. It has a very unique end grain anatomy made up of light colored concentric bands and the larger pores are usually clogged with whitish deposits. It's dark grayish brown overall color is somewhat like the wood in your photos.

Splintie, if you're going to keep digging up these mystery woods, you really need a good 20X hand lens.

Oh, i'm convinced about the lens AND Hoadley's book, and it will be done! I've known about the book ever since when, but given a choice of buying a design book or a tech book, i always opted to spend the funds on visual candy. To be fair, up until now, i always knew what wood i had.

I looked at ekki sites where it's described as coarse, machines poorly, and tends to warp, none of which describe this wood, which is fine and even-textured, stable, and while i thought it would chew up planer blades, it machined quite smoothly.

I'd already done some search on the web and thought it might be ipe. It's not used in this area yet for decking--western Montana has embraced plastic wholeheartedly--but i'll call around and see if anyone has a sample of it.

Failing that, could i mail a slice to you?

Jon: when you said "very unique feature to it's anatomy that sticks out like a sore thumb" at first I thought you might be referring to the same part of the male anatomy that Shirley MacLain observed in one of her books ... except she said it floats. So, I'm going to agree with those who say it's ipe. Except for color. All of it I've seen is dark brown beneath any weathered surface, and it does grey up when weathered. It also splinters like crazy, including when turned, but will have a glassy cross section when cut with a sharp blade. It also burns hot.

Splintie: I'll send YOU some ipe if you'll pay for the postage.

P.S. Nice photos.

So that's what the movie "Hope Floats" was about...

If ipe splinters badly, maybe this isn't. One of the other things i just noticed is that it doesn't have the shininess of bubinga or the rosewoods when coming off the planer or lathe, but a very "flat" sheen. No shavings off the lather, either, like maple, but "dust" better describes the waste. Sanded to 220, it still looks dull, like honed granite compared to polished. After 400 grit, it's a bit more reflective.

No..no..don't send me ipe....i want to find out what it IS, not what it AIN'T!

Splintie, I'm not sure I'd agree with what you're reading about ekki being all that coarse textured...But anyway, I'd be happy to take a look at a sample. E-mail me at: arno5@juno.com and I'll send you my postal address.

As for the Ipe article in FWW last year, it's one I wrote. If you can't find it, I can send you a copy.

I found your article and read it. I remembered having seen it, but i bailed on the issue around the point that a page was devoted to each of six ways to edge plywood. [Editors: more Jon, less plywood, s'il vous plait.]

The pic of the end grain shown on the lower right photo of the second page looks very similar, but i now understand why it's hard to identify with so many "looks" lumped in under the name. I've planed all the faces of my posts; all reveal a homogeneous dusky lavender-brown except for the roey VG. I notice in one of your pictures that the hand-planed shavings are scruffy--not curls--similar to my lathe experience.

I also dug out an old (1999) promotional packet i remembered receiving from Exterior Wood Specialties in NC about "Pau Lope" and studied their photos, but only one face grain example looked similar...while none of those several photos resembled one another, either. (BTW, there was also a testimonial from Kevin Ireton in the packet. <smile>)

An ancillary question: in the article, you name teak as endangered species well-replaced with ipe. My understanding was that teak has been extensively cleared in the wild (RAN), but grows well in plantations (Hawken et. al). I stopped using it bec of the price, primarily, but this teak-as-an-endanged-species question still comes up at shows. Do you have a 25-word answer that will educate my customers without their eyes glazing over? (Or tell me in which issue to look for your article, LOL!)

I'll prepare a 1/4" slice from each face and one from end grain to send you, if that's sufficient. Emailing you now...

Thank-you!

Colleen

Splintie, I'm not surprised you missed the Ipe article on the first pass. It got whittled down to only a two pager. The editors at FWW have this thing going now about not wanting to waste too much space on something as trivial as the medium of our craft. It interferes with the pretty pictures and the abundant white space that has been winning them art awards lately. (I'm hoping it's just a fad. I've weathered a few of those in the 25 years I've been writing for them.)

Anyway, as for teak, the wild stands of this timber have been seriously over exploited...and you're right, it does respond well to plantation forestry practices, both within it's native range and elsewhere in the tropics...So, it's not in danger of extinction.

The problem is, the plantation stock sometimes isn't as good. This species has a tendency to pick up silica, if grown in the wrong kind of soil. Also, when harvested on a fast rotation (which is the name of the game in plantation management) it doesn't tend to have the rich amber color of the wild stuff. I've also heard it isn't as strong or durable when plantation grown, but I haven't really looked into that complaint...so, I don't know for sure. The silica problem though, is for real and I think it's mostly associated with plantation stock now coming out of Africa.

Jon,

Is there any plans on continuing a series of articles concentrating on specific woods? When I read the artcle on Ipe, I told my wife that FWW should concentrate a few pages to that type of information, one wood an issue. It was disappointing to find nothing of the sort on the following issues. Well, I hope they change their minds about it.

Marcello

Marcello, thanks, but the best I've been able to do with FWW is about two articles a year (plus maybe a Q&A every other issue or so) and I haven't even averaged that over the long haul. Historically, they've avoided a serial format, forcing potential articles to compete for space on their individual merits (as judged by their editorial staff.) Personally, I agree with this publishing strategy (if not always with their editorial judgement :o))...since serializing a topic tends to lead to stagnation.

As for articles on wood, I'd be happy to write them, but getting FWW to publish more than a couple a year on this subject...or more importantly, getting them to commit more than two pages to a mere wood, just isn't a likely prospect...Maybe if Nature would come up with a wood that plugged in, they might give it more than two pages.

Jon,

Do you have plans on compiling articles on wood and turning them into a book? The books that I have found which indicate world wide woods are very brief. Not necessarily on the types of woods available, but on the information, history, uses, finishes, and characteristics of each wood. I don't know if there is anything out there in book format like your article. I have a feeling it would take several books to achieve that, but... it could be separated into, say, rosewoods, darkwoods, soft woods, northwestern woods, etc. Some may think it is boring but personally I find it a very intriguing topic to get to the cell structure and find out a particular wood's history and uses.

Just a thought.

Marcello

Marcello, in and around some health problems over the past decade, I've wanted to get going on a book much like what you describe. And you're right, it really hasn't been done...at least not in any detail or all in one place.

If I've got enough mileage left, I definitely want to write a more comprehensive collection of essays (summaries), but first on the cabinet woods of North America. Aside from the popular species within the various botanical families like; black walnut, black cherry, hard maple and red oak, we have a wealth of great woods that aren't getting the attention they deserve...In fact, many of them were better known and more appreciated in rural America during the 18th and 19th centuries than they are now.

Basically, I'd like to take each of our major, timber producing botanical families and flesh out all of this detail in as entertaining a way as I can pen it (i.e., not just as a compilation of dry technical facts.) I've tried to build some of this trivia into my magazine articles, but it's that sort of "who needs it" copy on the "also-rans" that typically gets edited out of what I submit to the magazine. For example, the original manuscript for that two page FWW piece on Ipe contained copy for a 3 to 4 page article. And the same has been true on virtually all of the other woods I've profiled over the past two decades.

What's happened isn't necessarily wrong from the perspective of what should be in a magazine article, but it sure weakens the copy's value as a meaningful long term reference. If I'm ever going to get it done, it will probably have to be in book form. I actually submitted this concept to Taunton about 6 or 7 years ago and we even pursued it to the point of doing some page mock ups, but the combination of my health back then and their editorial direction at the time managed to get the project scuttled.

I'll be giving it another shot. Probably by just drafting the manuscript solo and then worrying about how to get it published later. Sometimes it's easier that way.

Edited 2/1/2003 10:48:32 AM ET by Jon Arno

Jon,

First of all, I wish you improved health. I am sorry to hear of your ups and downs ragarding health. Just know that everyone of us goes through that rollercoaster, physically and/or mentally. Like my father said, life is a pendulum, up and down and up and down. When it is down, you know it can only come back up.

Second, once you have assembled your essays on cabinets, let us all know. I for one am willing to purchase from you a xeroxed, stapled copy, (if it helps you in any way), of the essays as you describe them. I strongly feel that such information is very important to be passed on, one way or another. I hope you have enough milage left, as you said, to finish and publish a work of that nature.

Best of luck,Marcello

Hi Colleen, Received the sample today, will ping you off-line later.

It's definitely a eucalypt, chocolate brown in colour, colour close to walnut, 1250 kg/m3 (ie: it sinks). Assume that it's fully dried. Colour is through timber, ie: brown colour is not due to light or oxygen exposure. Typical eucalypt smell, not too strong

Wavy grain like Jarrah, but with small patches of brown/tan grain, 3mm wide by 60 long.

My initial reaction was that it was a WA timber.

Local cabinetmakers/woodworkers - ideas?

Due to the density, my only choice is Cooktown ironwood, even though this is a Qld timber,

colour is right for gidgee, but the grain pattern's all wrong,

others?

Cheers,

eddie

Don't be too governed by the density -- it varies within the tree after all. I've had Spotted Gum (Euc. Citradora) that sank in water but according to the books its density is less than 1.0.The color, grain and hardness are right for Ironbark, (Euc. Sideroxylon) but it's a long way from home if that's the case.I still think that given it's in the States, it's Ipe.IanDG

Any ideas Phil

My two cents? It may be one of the Tingles, I'm not sure about the colour but the grain looks familiar. The thing that really make me think it is possibley yellow tingle or similar is the way it works with tools. I recently made a set of tables and used Yellow Tingle on the draw fronts. Its almost impossible to plane cleanly, so I used a scraper and sanded. Its horror hard and tears out even with sharp blades, it also leaves a fine dust all over the thicknesser cutter head. That said, it is able to be cut by hand (eg dovetails) crossgrain with sharp tools with a fair degree of success.

The description of how it finishes sounds pretty close to my experience as well.

Apparently a lot of this timber was sent around the world as railway sleepers (like most West Oz timbers......idiots), and also as structural beams. Someone said the South Africans were recovering old sleepers and using them for furniture. Also yellow tingle was used as telegraph insulators about 80 years ago, so I guess it turns pretty well.

I may be way out, but hey its worth a try.

Cheers

Phil

Eddie, the sample of Splintie's mystery wood arrived here today. It's amazing that you would have received your sample down there in Oz, before I received mine...

...But anyway, the wood is definitely Not the African timber ekki (Lophira alata) and its end grain anatomy is similar to that of your grey box (Eucalyptus moluccana)...but I don't think that's what it is either. I think it is one of the Tabebuia species in the Lapacho group, AKA one of the species marketed as ipe.

The clues I'm going by are the appearance of definite growth increments on the end grain ( some of these Tabebuia species grow in tropical forests that experience a definite dry season...and while they aren't really ring-porous, their pores do typically show some banding...not that this is exclusive to Tabebuia.) Also, the creamy whitish resin-like (actually I think it's technically a gum) deposits in the pores, which cause the wood to develop a soft luster when the smoothly cut end grain is hand rubbed. The density, texture and color would also agree with some of the heavier members of the lapacho group.

There is a chemical test that would probably confirm it, but I'm not equipped for that sort of thing anymore (the wife took away my chemistry set years ago when she found out I was making gun cotton out of the ends of her Q-tips.)...Maybe I'll sneak down and give it a try anyway. All I'd need is a little alkaline solution...so, not much risk of a flash fire. :o)

******Click on "view full message" button to see whole table******

Jon,

Tried to email you off line and it bounced (mailbox full).

I'll just do a cut & paste here of the body of the email.

Thanks on behalf of everyone for the work you do for the lot of us.

(Let me know if you need samples of silver ash or white beech for your collection of samples).

Cheers,

eddie

Apologies for the 6 month delay in getting these ready - once you see what's ready then you may understand why the delay.

I've had a devil of a time getting free time to get things ready for you, but here's what's ready to come to you. (all milled to 6" x 3" x 1/2").

Eucalyptus pilularis

Blackbutt x4

Eucalyptus marginata

Jarrah

Malaysian Red Cedar Heartwood (x3) (Toona Cedrani - 95% certainty, otherwise Kalantas)

Malaysian Red Cedar Sapwood

Monterey Pine

Pinus Radiata x3

Eucalyptus sideroxylon

Red Ironbark x2

Eucalyptus ???

Ironbark - sp unknown (there's at least 17 different species that go by the name) x2 (maybe Eucalyptus paniculata

Nothofagus Cunninghamii

Southern Myrtle

Casuarina torulosa

Rose Sheoak x2

Agathis sp...

Kauri Pine (x) either A. robusta or A. microstachya

Arthrotaxis selaginoides

King Billy Pine, More correctly King William Pine (x3 plus the balance of the block). Note - this smells strongly of Huon pine - must have been stored with huon

Tassie Oak

(one of three species - look almost identical) x2 Eucalyptus obliqua (messmate)

Eucalyptus delegatensis (gigantea) (Alpine Ash)

Eucalyptus Regnans (mountain ash)

Eucalyptus diversicolor

Karri (x2)

Acacia melanoxylon

Blackwood(x1)

New Guinea Rosewood

Syncarpia glomulifera

Turpentine (x5)

South American Myrtle

Flindersia brayleyana

Queensland Maple

I don't mind posting these if you don't mind accepting them all (38 samples). If they're a duplicate then you may be able to trade them.

Some of the above are planed, some are still off the saw.

The way things are looking, it might well be Xmas before I finish preparation so I'll send them off to you as is, if that's OK

As well, I have boards of Queensland Silver Ash (High end cabinet timber) (Flindersia bourjotiana) and White Beech (Gmelina leichhardtii) - let me know if you want a section cut off and included (I'll let you mill it at your end).

The white beech is the oily beech that I couldn't identify - I took it to my timber supplier (third generation of family in the business) and got him to confirm the identities of each coupon also.

Edited 7/12/2003 2:09:25 AM ET by eddie (aust)

Any ideas, Ian?

Really fishing here ...

Let's accept it's a eculypt and that it came from Australia. So what species would have been exported and why?my first reaction is some Aussie hardwoods were very popular for warves and warehouses - the various iron barks have excellent fire resistance and would be in square section and could be in BC on account of local timbers being much more flamable. 4 x 4 is an odd size for warf timber - most of it was exported as whole logs or very large sections. when it was used for planks it would have been sawn into rectangular sections 8 x 4 through to 12 x 4 not 4 x 4 - so I'm thinking unlikely that it is black butt or turpentine. also unlikely to mine timber as I'm thinking there's enough local (in B.C.) lumber for that purpose.

If could well be from a recovered / recycled warehouse - 12 ft long could sort of match a typical warehouse bay. If it is from a recycled source it would be very well seasoned - hence the minimal checking - and being old growth the grain structure and colour could easily be a lot diffeent to what we see in today's new timber.

My guess is that it's unlikely to be exotic (in the sense that Australian cabinet timbers are exotic) so most likley a construction grade material - which for eculypts means hard to work so again I'm thinking warehouse, iron bark, recycled.

How about Mullberry????????????????????????????

Old Mullberry?????????????

Maybe?????

I dont have a clue?

This forum post is now archived. Commenting has been disabled