Newb Glue-ups slightly cupped. Rip and redo or mow down on drum sander?

First time poster, long time lurker.

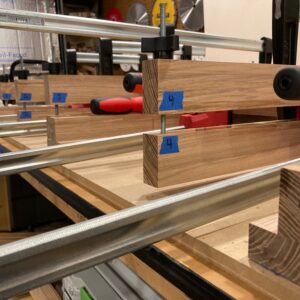

I’m doing my first “big money” panel glue up project. Making a tv stand/AV cabinet out of 5/4 walnut. I have 5 panels I’m gluing up. (2) approx 20” x 48” and (3) approx 20” x 72”. Each glue up is (4) 5” wide pieces. I did some homework and thought I was 100% ready. I made 5 sets of hardwood clamping cauls. Have 8 parallel clamps, and 6 bar clamps. Made 3 T-shaped hard wood “stands” for the panels to sit on. Meticulously leveled the 3 stands on top of my workbench so I had a flat surface. I did the trick of jointing each mating edge to create a complimentary angle. Alternated top and bottom for the clamps.

Anyway, my first 2 panels came out slightly cupped, one about .008” across the 20” span and the other about .011”. Not terrible, but not ideal. I did some more research and suspect I had the clamps tighter than they needed to be. The next 2 I clamped just enough to “bring the panels together and squeeze out the glue” as I read elsewhere on this site. They came out flatter than my workbench. Like better than .002” Live and learn I guess.

I just bought a 19-38 drum sander for this project and am planning on running everything through it. So my question is, do I shim the cupped panels with blue tape and flatten them on the drum sander? I’m guessing I’ll need to mow about .015” to .020” off of each face of every panel. Or do I rip them apart, re-join and reglue? I have an extra inch of width on the panels. I figure I need about .5-.6” for rip kerf and and edge jointing, but don’t have enough meat left on the bone to do any face jointing or planing if they come off the saw wonky.

I am planning on doing through dovetails for the four carcass corners, so I need these panels flat one way or another.

Appreciate any sage advice.

thanks, joel

Replies

You are dealing with hundredths of in inch. I wouldn't worry about it until you get to final sanding stage. The wood is always in motion. By tomorrow it may be bowed the other direction. Just curious, did you plane the same amount from both sides of the wood?

Thanks. I’m definitely stressing over minutia. The first 2 have been out of the clamps for 2 days and have improved a bit.

I tried to take the same amount off both sides. The boards in the rough were all bowed a bit, so I ended up milling them all down to about 1” before glue up. Sure was easier to straighten the 48” boards compared to the 72” :)

That small cupping is not to worry, when you make panels out of 5/4, the finished thickness is expected to be one inch so you have close to 0,250 to play with . However, for a full strength glue joint it takes more than contacting the surfaces, so just making them touch is not a good idea, you need all the force those clamps will give and ideally more.

Thanks. So even when joints align really well, I should crank down on the clamps? I have been closing the joints and stopping when I feel significant resistance.

I think you did the right thing, I wouldn't recommend extreme clamping force.

I can fix your problem.

THROW AWAY YOUR FEELER GAUGES.

It is a rare thing to get a panel glue-up perfectly flat. Close enough is good enough in almost all cases.

It should work out fine whichever way you do it, but it will certainly pay dividends if you can get the panels into the surrounds as soon as possible.

Totally agree, it's wood, no one would ever notice such a small warp.

Congratulations are in order for you. You did everything exactly right. I doubt the fanciest grade of plywood is even that flat... Lets put this in a little perspective: approximate average hair diameter is ~0.004" so you are dealing with 2-3 hairs cuppage across 20". That is a very flat panel.

As other posters mentioned the wood will always be moving to equilibrate to the environment, so you may discover it will change a bit day-to-day.

Move on to the next step... Good luck.

There’s a very good chance the overall carcass dovetail joinery will square up and flatten out that which you can micro-measure, but barely notice.

I'm a bit of a closet perfectionist. When I edge glue I add an extra piece of 3/4" scrap under the cauls, on the joints & outside edges. One thing I can add, though, is watch the glue you're using, especially on oily woods. Regular yellow glue is good for most projects. Polyurethane glue is good on oily wood such as rosewoods,teak, walnut. I like "Old Brown Glue" for edge/edge glue-ups.

And personally, if you're measuring in hundredths of an inch you gotta relax. Woodworking is supposed to be fun.

I agree that you have done a good job getting the panels that flat. If they are seeming a bit cupped when you are ready to cut the dovetails, clamp straight battens across them to straighten them out as you do the joinery. Then when you glue up the dovetails, all will work right and the panels will be held flat.

It is important when gluing up panels that there be no unbalanced pressure from one side compared to the other. It can compress the edges of the wood (and the glue) more than the other side, leading to a cupped panel when all dries.

Those panels are as flat as they will ever get. I have built dovetailed projects with longer panels, which resulted in a pet project of mine and a couple of patents now winding through the system. I mark out while avoiding the transfer step:

https://www.youtube.com/watch?v=XLvXNg0tmc4

Thanks for all the advice everyone. The more money I spend on wood and tools makes me feel I need to achieve higher levels of precision. I will freely admit woodworking hasn’t been as fun since I incorporated a dial indicator, precision straight edge, and micrometer. I should probably just leave those tools in the toolbox—except for machine setup.

In all honesty, I think I needed to hear people tell me I’m insane :)

Those three tools are sure handy when you do want your machines to work accurately. I'm glad to have them but, as you say, they rarely come out except for machine set-up, for which they are almost essential. Where thousandths of an inch are critical in wood is for mortise and tenons. A few thousandths can make them rattle instead of being tight.

All true what they say -- but then again you HAVE the drum sander! It's OK to be obsessed and driven in your work. Who's making up this rule that it's supposed to be "fun"?

There is a slight difference between machining wood and being a woodworker.

You did everything right.

I keep all my panels clamped in cauls, preferably in a climate controlled room or where its going to live until ready to finish and/or install.

While i won't take the bait and call the OP insane, I will say put down the digital calipers and breathe.

As a general blanket statement, stop trying to measure to the thousandth of an inch. You'll only drive yourself mad and rarely will the project benefit.

As for getting precise fit, I go by feel, not a micrometer.

Test fit, test cut and let your eye be the final judge if something looks good, not the plans.

You simply can not transfer the tools and mentality of a machinist to woodworking. Wood is organic and no two pieces are the same. Every build is different.

This forum post is now archived. Commenting has been disabled