I recently was able to bring my entire machine shop out of storage after 14 years. One of the table saws, a Powermatic 10″, has a Paralock Fence. One of the parts of he fence is misplaced (I hope not lost). I went on line yesterday to see if the company, Quintec, was still in business. To my disappointment I saw that they have been out of business for some time.

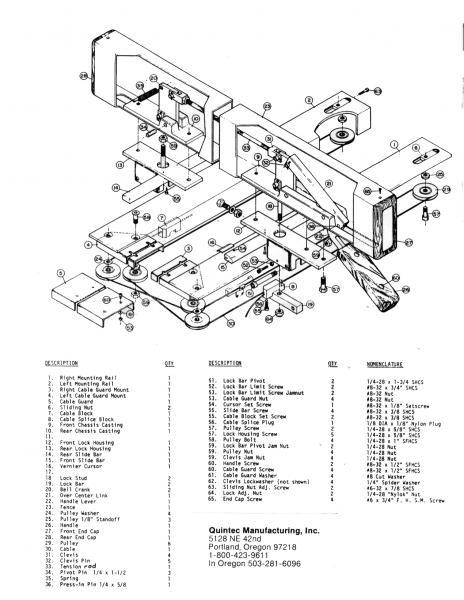

Many of the posts I saw on forums were from folks trying to find the manual for the Paralock. After a search for my manual which must date back 25 years or more I found it. I scanned the 6 page sides and converted to PDF format.

I hope it’s of some use to anyone still trying to repair or adjust the Paralock Fence. The part I can’t find yet is the Cable Guard and won’t be too hard to fabricate in the event it doesn’t show up.

Paul

Replies

Not hard to make one

It is actually not all that hard to make a paralock type setup using a stock fence.

Aluminum blocks, some small drill rod (around 0.125 or so) set screws, machine screws, drills, taps and a bandsaw to cut aluminum.

Use steel wheels as used on sliding doors for the sheaves.

Drill and tap the top of the table saw and makes a framework for any extension table underneath.

i used two blocks for the front of the fence with guide pins from drill rod and a machine screw to tension things up.

two horizontal wheels on the extension table, two vertical wheels on the left side of the saw top.

1/16 inch aircraft cable.

The cable ends are in the front under set screws in each block..

Tension the cable with the rear fence block NOT tight on the cable.

Square up the fence to the mighter gauge, then tighten the rear set screw.

Mine holds better than 0.0001 (checked with a dial indicator to the table slots).

With zero play it stays straight as it moves, and does not even wiggle when locked down.

One of the other WW mags even had an article about it many years ago.

Now if I can only get the slight bend the movers put in my rails out enough.

This forum post is now archived. Commenting has been disabled