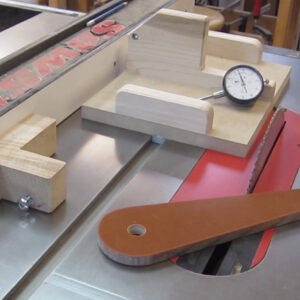

Precise Alignment of Table Saw Blade with Slot and Fence using only a dial gauge and simple shop made fixtures. Demonstrated on SawStop ICS

Inspired by the book: “Shop Machines” by John White, I found that I could get excellent results with shop made fixtures. The only expensive thing to purchase is a good dial indicator.

Blade alignment on a table saw should be checked at three blade positions: 1) vertical at maximum height; 2) vertical at minimum height; 3) bevel 45 degrees at maximum height.

Some table saws, such as SawStop ICS, have separate adjustment for each of these alignments, but even on a saw without separate adjustments it is good to know what the alignment errors are.

Most instructions for alignment say to measure off of the blade. A better approach is to replace the blade with a rigid arm. I used 1/2 inch phenolic for the arm. An arm has two advantages, over a blade: 1) deviations on the dial gauge are amplified, which gives a better indication of the alignment error; 2) when the blade is at minimum height the arm still projects above the table so a standard dial gauge can still be used, whereas with a blade, a special vertical dial gauge would be required.

Photos below, Video here https://youtu.be/tOHy69VmNwk

This post is archived.