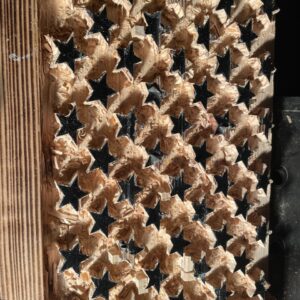

I’ve made several flags in the past, but I’ve always carved out the stars from the “Union” either with handtools or a router depending on the depth I wanted, never has any issues. But this time I decided to carve out the blue area in the “Union” leaving the stars alone, then fill in the area with 556 ammunition casings with blue tinted epoxy. To do this I used my Makita Palm router in its plunge base and used “upcut spiral bits and then used chisels regularly sharpened to clean up the work. The issue is that the points of the stars kept breaking off during the process and I had to constantly stop and make replacement pieces to glue in. The wood I used for this project was Douglas Fir, and I was hollowing out to a depth of 1 inch, which I broke down into 3 increments.

What could I have down to prevent these pieces from breaking off? Would it have been better if I had used a “Down-Cut” or “Compression” bit, or perhaps I should have used my full sized router to have more power behind the bit? Or should I just use harder woods in the future?

Thank you for any tips or advice.

Discussion Forum

Get It All!

UNLIMITED Membership is like taking a master class in woodworking for less than $10 a month.

Start Your Free TrialCategories

Discussion Forum

Digital Plans Library

Member exclusive! – Plans for everyone – from beginners to experts – right at your fingertips.

Highlights

-

Shape Your Skills

when you sign up for our emails

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. -

Shop Talk Live Podcast

Shop Talk Live Podcast -

Our favorite articles and videos

Our favorite articles and videos -

E-Learning Courses from Fine Woodworking

-

-

Fine Woodworking New England Event

Fine Woodworking New England Event -

Replies

I think the doug fir was a bad choice. A tight-grained hardwood would hold together much better. I also think taking an inch in just 3 passes is too agressive, even for a regular router.

This project screams for a CNC or maybe a series of short-to-long router bits with upper guide bushings. Once you complete your first pass you could switch to guided bits to avoid the crashes that will destroy the corners of the stars.

Yes, I’ve been saying for years that all my life’s troubles would be fixed with a CNC Machine, unfortunately my wife doesn’t agree. All joking aside thank you for the advice, I’ve been debating awhile getting a CNC the biggest holdup is I don’t really have any free space in my shop, so I’ve tried figuring out which tool I could move or get rid of. I’ve seen some people use CNC’s to flatten slabs with a surfacing bit, so it made me think if a CNC could replace my Planer in the milling process, or would it be too slow?

Lighter passes, higher speed and a straight or down cut with more flutes would be better.

Up cuts tear things upwards, so it could be contributing to your issue.

You probably don't want a compression bit because they're an up cut for the first 4-6mm (and I think that's too deep a cut for what you're doing here). Really compressions are best for laminated material where you want a good finish on both sides and you have a strong router/bit/CNC frame/can take deep cuts.

Doug fir tends to separate between the dark and light grain. Worst splinters I ever had was from running my hand along the edge of douglas fir that I had just smoothed. Really tight verticle grain is better but not so easy to obtain anymore. Poplar is one wood that has a tendency to not split. It's relatively soft and easy to work, not very pretty on its own is its biggest draw back. A genuine hard hardwood would be best but harder to work as well.

I can't tell from that picture what I'm looking at but I would think making stars like that that (short of lazer cut or cnc )a scroll saw might be the tool for the job. Scroll saws secondhand for some reason have a really low resale value. Scads on Craigslist.

There is an article in the current FWW of a guy making a complicated veneer pattern with one of those two part inlay router guides. Might be of interest to you.

Basswood, also known as linden. Carves like buttah.

I am always looking for the easy way out. Not what you asked, but would you consider buying pre-made stars (craft stores) and gluing them in place?

Agree with john_c2 on basswood. No chips on 250 sharp points standing 1" tall, at all angles to the wood grain, is a lot to expect regardless of wood or method. Dedicated, carving sharp, carving tools, hand or power, would probably give better results. Tapering the cut away from the star points as one goes down would also help. There are some dedicated wood carving forums that would have more insight.

This forum post is now archived. Commenting has been disabled