Not that I am a pro. I am not. I am an enthusiastic amateur.

For anyone who cares :

The recent FWW sharpening stone tool tests seems to have skipped over the Shapton Pro stones now called “Traditional ” stones.

The reason I am even getting all excited about sharpening stones is kind of a lengthy tail. I will attempt to make it as brief as I can.

Since my new hand plane from one of the fine wooden plane makers, my first , seems to be delayed and since that was my main almost only christmas present I asked Santa for . . .

small tear sneaking out of eye and down cheek . . .

sigh . . .

Where was I . . . oh yah . . . I decided to go for the second “FUN” thing on the ” I just gotta get that one day ” list which was chunks of sharpening stone that I can hold like mini “sanding blocks” to polish the sides of knives with. Some times I mess up sharpening a knife and I scratch the polished part of the side of a knife.

Yikes @%&^ ! ! *&%^$

I have had a hard time finding what I wanted for this so I was going to buy some Norton stones in the three finer grits and brake those up and use them.

I read a review recently posted buy a wood worker who had one of the old Norton 8000 stones, among the others, and he wore it down after many years and bought a new one. The new one was marked ” Made In Mexico “.

Hmmmm

So he puts it to use and finds that it is inferior and has coarser grit in it that scratches his plane blades all up. So he put that in his review.

I don’t know this person and you can take that for what it is worth. His comments seemed like he was quite experienced and was a competent sharpener/woodworker. I don’t know if it is really worth posting the link here but will if any body gives a darn.

Hmmmmm

What to do ? Those things are expensive. Might get less than I am used to.

Hmmmm

OK that does it ! I am going to go whole hog and do what I really have wanted to do for a long long time . . .

Get all Shapton stones because :

- They come with the cool boxes ( his blue box from Norton that just started coming with the new stones broke/ was broken when he got it and missing feet ).

- I have wanted separate boxes for all the stones for a long time.

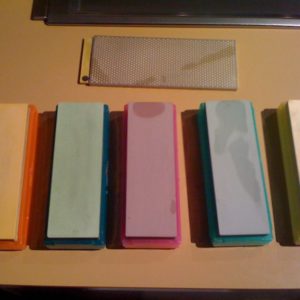

- I like the colorful array of all the Shapton stones. Call me a bad word, question my orientation and masculinity I don’t care. Just don’t step on my blue suede shoes.

I already had a 2000 Shapton and a 15000 (I am not going to defend that I just like that too ) for quite a while now.

So

I orders me a 1000, a 5000 and an 8000 to take the place of my Nortons and ( if I like the Shaptons as well as the OLD USA make Nortons ) then I will brake the Nortons up to use to polish knives / what have you with.

I received the three Shapton stones this morning and after work I checked them for flat and put them to work.

I sharpened an LN O2 blade from my LN low angle jack ( because that was what was needing sharpening ).

This particular blade has some camber, was usable sharp but was about shot, the secondary sharpening angle was 45 ° and quite wide; on the order of three or four mm.

I started in with the 1000. Usually I start with the 700 stone or my 320 diamond plate but I wanted to see how the 1000 did.

Worked great ! I got a very small wire edge in no time.

The other stones cut fast and seemed to be a bit more pure grit size wise than my old Nortons. The Shapton ceramic stones have a different feel to them. They are harder and SEEM, what I would call , “stiffer” or more rigid than the Nortons. I know the Nortons aren’t actually flexing but that is the best I can describe it.

In the end I got a better mirror, less / almost no scratches in the mirror, and removing the wire edge went much better, faster , easier and my “shave curls off a single hair viewed under magnification ” test was faster / easier to achieve. Some times with the Nortons I don’t get that at the end and have to back up a bit.

Sure the blade shaves like crazy even then but the curls off a single hair is what I look for to be sure the edge isn’t dubbed but sharp.

I am very glad I went this buying all Shaptons route . The FWW sharpening stone test put the Nortons ahead of the Shaptons in speed of stock ( steel ) removal while sharpening.

THEY WERE TESTING THE GLASS SHAPTONS

THE PRO SHAPTONS THAT ARE MADE FROM ALL GRIT AND CLAY (NO GLASS) SHARPENED FASTER AND BETTER THAN MY NORTONS !

I may as well plug the source I have used for all my Shapton stones because they are great to deal with and super fast shipping and sell the stones at a very fair price . . .

http://www.craftsmanstudio.com/html_p/Q!0P0000.htm

So . . . that’s what I been about lately.

Any body bought the Mexico Nortons ?

Comments ?

PS: I should be able to eliminate these stone soaking tubs. That will consolidate things nicely.

PPS: I almost forgot. See that white stone in the third photo in front of all the stones put away in the nestling boxes ? 80 grit baby ! Yah baby !

: )

I found it on Amazon for working with tile. $ 7.00 plus some shipping.

I haven’t tried it yet. I’m scared.

Replies

It's your time and money, Roc, enjoy yourself. As far as sharpening woodworking tools to do woodworking, 5 or 6 strokes on a 1000 grit stone and about the same on a leather strop gets me back to work unless and edge gets chipped which isn't very often. Sharpening to the Nth degree doesn't make me any money or make my tools work any better.

roc Strop . . . I used one when I was younger but don't now.

: )

Hammer1,

You are easy to please I will say that.

I have tried the one stone and strop.

You have already tried the the multiple stone systems approach with no strop so there is nothing new I can tell you.

Right ?

I'll meet you half way; I started with the brown stone in the photo about a hunert years ago ( bought it around 1983). It has been so long since I bought that stone I am not sure if it is a 1000 or a 1200. I bought it before I was doing any woodworking I just wanted to sharpen other stuff and wanted a good stone.

When I got all serious about learning woodworking I heard about stropping. Used mostly for carving chisels. The small rectangle was my first strop. Worked OK for carving chisels and knives and such. For plane blades I wasn't getting the results I had read about and my plane was behaving oddly. Cutting for a short while then kind of skating after it got a bit dull. The results were it would cut on the start but not as well or as deep in the middle of the board and caused a crowned surface. For the longest time I had no idea why.

I figured I need a "better" strop so I made the big long honker that you see in the photo. Note the brass screws holding the leather to the scrap wood.

Oooooh yah, brass screws.

Well that didn't improve things; still bad plane behavior. "Sharp " blades though. They pulled at my arm hair and cut hair off and felt all sharp and stuff.

I thought " must be using the wrong abrasive on the strop". I bought yellow, I bought green, I tried jeweler's rouge. Not in that order but you get the gist.

Then I read about the maple wood "strop" with diamond compound smeared on it. See that in the middle of the photo.

Hey ! ! ! Now this is starting to work ! The plane is PERFORMING with a capital . . .

Do you see where I am going with this ?

Finally I put the maple strop on the shelf and bought some finer stones and haven't looked back.

Until now.

SO

I will know when I am really getting the hang of this sharpening thing when . . .

I can get the same performance using that one old 1000ish stone and that hunk of leather.

I have a long way to go.

I am so addicted to the good stones.

I need help.

Is there a clinic or a program for sissy assed too many stone users ?

I know what you are going to say Hammer1

YAH . . . TRY TO MAKE A LIVING AT WOODWORKING GOING AT IT THE WAY YOU ARE. THAT'L CURE YOU.

You got a point there.

I am afraid if I had to use one stone and a strop I would have to make up for my bad edges with horse power and sand paper.

I don't like noise, I don't like cleaning my shop vac ( let alone a dust collector system ). Sweeping up curls is OK.

Call me a candy.

on being boxed in by sharpening

The Shapton boxes are cute. The colors remind me of Miami chic, as seen through the eyes of, and popularized by "Miami Vice" on TV. But, Shapton missed the point here. The sequence of colors is illogical and says nothing about the grit. Tch, tch. ;-)

Well you don't want them to make it too easy do you

>sequence of colors is illogical and says nothing about the grit<

It is all in code. I have heard that if you first watch the two movies True Grit and then watch The De Vinci Code and watch them all in the same night that all will become clear. Do you think those guys were just messing with me ? Again ! ?

Oh mannnnn

I'm so happy for you roc.

On the down side you now have to get a complete new wardrobe to color coordinate with your new stones and boxes. A tie with a simple stripe would be best I think, but what do I know?

(snide remarks to hide jealousy}

new wardrobe to color coordinate with your new stones and boxes

Well Yah !

And leather with these colors ?

They just are not doing that on the continent this year.

And what about pearls ?

Hey There is One Of Those Meaheco Norton Stones

I was cruising around and found this site

http://www.theunpluggedwoodshop.com/a-dedicated-sharpening-bench-part-8.html

Finally got the perfect coarse stone.

I sound like a Shapton commercial but it is rare that I get this excited about a product. I have been buying stones and things and searching for this outcome for years and years.

To test out my new Shapton 120 I worked the blade I am making out of a file. See second photo. I ignore the little files sitting on the top stone; this photo was for another post. I had ground the teeth off of the big file and put a main bevel on nearly down to the edge with a power grinder. I had been working a secondary bevel toward the end/edge using my new white 80 grit tile workers stone and a grind stone grading stone that is made up of chunks of carbide grit. These were disappointing and didn't cut nearly as well as I had hoped and I finally had kind of a rounded bevel just to keep the stones cutting.

Then I started in with the Shapton 120 today.

As the secondary bevel kept getting wider and wider ( 5.5 millimeter ( 7/32 inch ) ) though the bevel became flat the stone just kept cutting and cutting until I had a wire edge. When I started today the end of the main bevel was a blunt square edge from the original 90° end of the stock.

Keep in mind this is a file that is a bit harder than most any commercially available plane blade or chisel.

With the 80 grit and others I would keep changing the angle to work a narrow high part of a curve so the surface pressure was increased.

I couldn't get anywhere near getting the secondary bevel down to the end for a wire edge. This Shapton 120 just cut right down there and I got my wire edge.

Unlike the Norton coarsest 220 the stone had some loose grit on it after working the bevel for a while but didn't wear noticeably and had tons of black metal in it. If I were using my Norton 220 it would have just worn away a whole lot of the stone and gotten all sway backed and the grit would have acted like ball bearings rather than cut metal off the blade. I had completely stopped using that Norton for those reasons.

The metal almost totally washed out of the Shapton 120 under the kitchen faucet and away we go again. When finished I put some pencil lines the length and width of the Shapton and made about three or four rubs on the DMT flattening plate to check for flat and the Shapton was so close to flat all over it wasn't worth flattening it. I could barely see all the lines, some worn off, so it was quite flat enough for an extra coarse stone.

Yah this thing blew the 80 grit ceramic tile stone not only out of the water but off the planet. Using the tile 80 I worked the blade a long time, not nearly as much metal came off on that stone and it kept getting smoother to the touch ( the Shapton kept it's rough / sharp feel to the touch ).

So

As we all know it isn't just the grit size but how it is bonded and how it fractures that makes it keep cutting and not wear too rapidly.

If you make your own blades or change from steep to a shallow cutting angle this stone can be a stellar alternative to a power grinder and a well made ( $ ) tool rest for it. No chance of over heating the edge. No sparks to ignite your shavings and saw dust that you don't have time to sweep up right now.

Yes this stone cost twice as much as most 80 to 220 grit stones but it is so well engineered the price is worth it and more.

As I said a few days ago these new Shaptons freed up my other stones to be turned into small abrasive blocks so I can hold them like crayons or little sanding blocks for polishing various things like the sides of knives where I accidentally scratch them. I scored and broke the old stones today. See photo

So, then...

do you go right to the Shapton 1K?

Depends . . .

Some would and be fine with the results. Experiment to find out what level of edge quality suits you. It is time verses results/returns.

I don't sand so when I want the best surface possible off the finish plane blade I go through many grits to refine the edge.

For some applications such as scrub planing maybe 120, then 1000 then strop on a buffing wheel would do fine.

Well, since I have one of these already I use both sides of this :

http://www.highlandwoodworking.com/dmtduo-sharp10diamondstoneextra-coarsecoarse.aspx

The extra coarse side is 220 grit and the coarse side is 325.

Also I use this stone to flatten my other stones. Other wise I would buy the equivalent Shapton ceramic stones.

I did mention in the earlier posts above :

>Usually I start with the 700 stone or my 320 diamond plate. . . <

I pretty much have stopped using the 700 stone and go from the 320 to the 1000.

This forum post is now archived. Commenting has been disabled