Rebate plane and plough plane not producing square cuts

Hello

So I got Stanley 78 as well as Stanley 13-030 plane and got very enthusiastic since I though I would be able to produce nice rebates and grooves.

Rebate plane:

The iron is square (no camber on it) and protruding 1/4 of mm beyond the plane side. So it should cut into the wood without problems. I sharpened the iron and it is producing good shavings. I grab the plane on the side (as suggested in the manual) to try to keep the fence on the wood. I did check if the fence is completely vertical (to the bottom of the plane) and it is not, however I have no idea how to repair this.

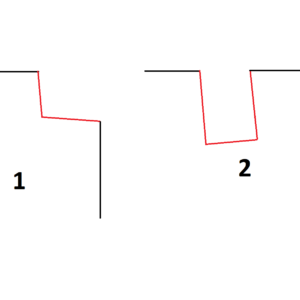

The cut it just not square, so I am not getting 90 degrees rebate (see sketch 1, cross-section). The slope of the rebate bottom is very visible and the side of the rabate is not vertical.

Plough plane:

Same thing, iron protruding a little bit, sharp and positioned as it should be. The cut may be square inside, but the bottom of the cut is not parallel to the upper surface of the wood (see sketch 2, cross-section). It looks like the groove sits under angle in the wood.

Not sure what I am doing wrong. Any ideas?

Replies

First, the plane iron should not protrude beyond the side of the plane, it should be aligned with the plane body which is square to the sole and used for registration. If the fence is not parallel to the side of the plane and you are pressing it to the wood you are throwing the plane out of alignment in relation to your work. Most likely the rod is bent. Roll in on a flat surface to check it.

Holding the plane upright is really more a matter of learned skill than pressing on the fence, which is really more of a horizontal depth stop.

I agree with MJ. It took me a while to learn how to get square grooves with my plough plane and mine had no issues. The rebate plane still is hard for me to use. First, confirm nothing wrong with the tool.

I read on Paul Sellers blog that the iron of Stanley 78 should protrude a little bit, there is also a photo of the blade:

"The 2mm of extra width beyond the width of the plane itself creates a relief between the side edge of the cutting iron and the plane body without which the plane stair-steps away from the intended cut line with each and every subsequent cut or stroke of the plane."

https://paulsellers.com/2016/05/rebate-plane-no1-78-filletster-plane/

Or do you refer to the plough plane here?

I just described what works for me. Taking a cut out past the mouth of the plane does not make sense... Paul and I will have to agree to disagree. (I did not use the link)

I think what Sellers is driving at is making sure you don't introduce a step in the rebate - same reason a shoulder plan blade protrudes slightly from the side of the plane - it ensures the blade gets right into the corner and a step isn't introduced. That said, protrusion or not won't affect the squareness of the rebate. Either the fence is bent as someone alluded to here, or the technique needs work. I have a veritas shoulder plane, a #78 and a Record 044. They call cut rebates square as they should. And the blades all protrude ever so slightly from the body. ;-)

What you recommend doing/exercising to get better at doing rebate properly?

Shoulder planes and rebates should indeed have blades protruding a teeny bit beyond the side of the plane, on the side of the cut. I go by feel. I've never tried to measure.

Technique is really important with these. It's really easy to wander and get a leaning or stepped rabbet. It seems like it should be super easy, but it takes some practice.

I've never been a fan of the Stanley 78. I love the Veritas skew rebate. That plough plane -- I've never seen one.

Veritas looks nice, but it is out of my budget for now. I did see an alternative - Record 778 which has better fence on which additional wooden fence can be mounted.

https://www.findmytool.co.uk/record-fillister-plane-778-review.php

But basically I obviously introduced steps so every time the plane slides a little bit to the left and produce poor results.

Stanley 13-030 is just a normal plough plane and I will try to put wooden fence since there are two holes available on the metal fence. Maybe that could help solve the problem.

I got Record 778 and after putting additional fence on the existing metal one, I got better results. After a little bit of adjusting the wooden fence (to be completely parallel and square to the sole of the plane) I produced at first try square rabett. At the end of the rabett there is a little bit of inconsistency but overall I am happy with the results. The rest will be experience I guess.

The same goes for the 13-030.

Not sure how this tools meant to be used without additional wooden fence (there are however holes available) because keeping the tools perfectly vertical is a real challange.