I inherited a set of Stanley Sweethart 750 chisels – most of them never touched – from my wife’s cousin. I’m attempting to get them in good working order and I need some guidance here.

First question is about flattening the chisel backs.

I’ve been working on flattening the backs of the chisels using a Trend 8″ Double-Sided 1000/300 Diamond stone. I’m using the 1000 grit side but I’m making very slow progress as some of the chisels – the bigger ones of course – seem to have bellies and getting the flattening to reach the cutting edges looks to be literally a days-long process.

I’d like to flip the stone over and use the 300 grit side to achieve the basic flattening and then finish off with the 1000 grit, but I’ve seen YouTube videos, (e.g., Stumpy Nubs), claiming that removing the coarser grit scratches with finer grits will make the process even longer than simply sticking with the 1000 grit. Intuitively that claim seems false – why do woodworkers start with coarser grits of sandpaper then work to finer grits? – but maybe because you’re “sanding” steel it works differently?

Any strong opinions one way or the other about that?

The second issue deals with getting a square edge on a chisel.

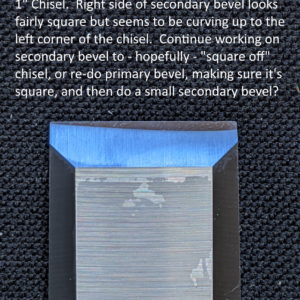

I’m using an eclipse style honing guide to establish the secondary bevel, setting the angle of this bevel at + 5 degrees and using the 1000 grit side of the diamond stone to establish it. On the 1 inch chisel it took quite a few strokes to get the secondary bevel established across the width of the chisel. (First picture attached.)

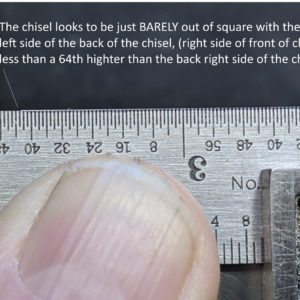

I’ve been as careful as I can to not rock the honing guide and to move it back and forth in straight strokes. The chisel does look to be very, very slightly out of square with the longer side of the chisel being the edge with the wider secondary bevel. (Second picture attached.)

To my eye is looks like the chisel was somewhat out of square “out of the box” and that my honing is bringing the chisel square. I’m guessing that’s the case because the line of the secondary bevel is slightly curved, while I’d think a consistent error on my part in using the honing guide would produce more of a straight-line “skew.”

So here’s my question: Is my guess correct and should I just continue honing and come up with a square chisel with a wide secondary bevel, or, should I go back to the primary bevel and work that “square”, and then do the primary bevel. (Or, am I completely at sea here?

Replies

Yes, go 300 or you'll be there all day on one chisel. Heck, even at 300 it can take a while!

Are you grinding a new primary bevel? If not, then the edge may be slightly out of square. Sometimes, straight from the factory, it's not square. But, it could be the wife's cousin may have ground them out of square as well. I cannot tell you how many chisels I have that had out of square primary bevels when I first got them!

When I've procured new-to-me chisels, either buying or inheriting, I go through a full set up. I flatten the backs and polish them to the highest grit I own (currently that's 16k). Then, I will use my Veritas honing guide to establish the primary bevel (these days that's with the 300 grit side of my Trend stone). On a Western chisel, this gives me a nice right angle on the cutting edge. Then, I will do the secondary and tertiary bevels by hand in progressively finer grits.

THREE BEVELS?!?! You kwazy.

@FiveBirdsCustom

Thanks for the information.

Would your advice be to re-do the primary bevel to "square" and then go on to the secondary bevel at this point? Or is the chisel "square enough" according to what I've shown in the second picture and completing the secondary bevel such that it's evenly wide across the chisel be OK?

Sorry not to have answered quicker, I've been slammed with work (a good thing these days) and haven't had time to spend on forums in a day or two.

Yes, I would square up the primary bevel. As someone said more eloquently than I, then you just know.

As long as your secondary bevel is square, I wouldn't worry about it it will eventually correct itself and to do otherwise now just wastes metal and time IMO. The cutting edge is the only thing that really matters, everything else is for show.

esch5995, right on. Does the edge cut the material you are working? You must have the edge that works for the material. Are you working pine or curly maple? Getting the back flat at the cutting edge is essential. Concave areas in the rest of the back are irrelevant. The bevel edge must be straight, not irregular, across it's width. But some skew relative to the sides won't affect the cut, and may improve it, depending on how you hold the tool and whether you are paring end grain. Scratches and polish? How much do they really affect the cut? Use the chisel and find out. Some of the You Tubers may be a bit compulsive. How could they have survived before the advent of water and diamond stones?

Also with @esch5995.

As long as the cutting edge is squarish it will work. I have a couple like that and just accept the grinding was a tad off - the secondary is what does the cutting.

@TGY - 5birds nailed it. Good luck. You'll never look back and wonder, hmmmm... is there a better way. Other than getting someone to commission your chisels and maintain them you'll now enjoy woodworking since sharp tools put you in the zone instead of struggling to get it done and having those, "ouch - did I really do that" moments.

Thanks for all the responses.

I've put in lots of hours - probably at least a cumulative couple of man days at this point - trying to get the backs of the chisels flat and polished up to the cutting edge on the 1000 grit side and I'm not there yet. Maybe that has something to do with my technique, maybe the batch I inherited were sub-par, but I'm moving on to the coarse side for the largest 2 or 3 and will see how that turns out.

On the one chisel where I started to create a secondary bevel - the one pictured in my original post - I didn't think to check for squareness before I began that honing process, but I'll certainly do so on the other chisels.

Tgy,

If your impression that the back of the chisels are bellied is an accurate impression - i.e. tha backs are convex - then you will likely never get them flat unless you use an expensive machine like a surface grinder.

The reason bellied backs are a nightmare to flatten by hand is that it's very hard to impossible to hold the chisel at the same horizontal position as you rub in on the grinding medium. You will tend to rock the chisel front to back, with the high point of the belly being the fulcrum. As a result, you merely thin the chisel a teeny bit but leave the belly as-is .... or not significantly flattened.

You might stand a chance of rubbing a bellied back flat if you use a quick-acting grinder such as a high quality belt sander, upside down. The sander will need to have a genuinely flat platten under its belt; and you still need to somehow hold the chisel exactly in the same plane until it becomes flat. If not, you make a still-bellied chisel that's somewhat thinner than before.

I speak from experience. I once bought a pair of Crown bench chisels with bellied backs. I did eventually sand them flat, with a ginormous floor-standing belt sander and a lot of cursing. (It frightens the chisel into behaving). :-)

Lataxe

Yeah, you're right about not being able to keep a bellied chisel flat, but I think it's still possible to get it to a working condition. Any rotary tool with fine grinding bit would remove a belly. It's would take few passes to take any meaningful amount off so the process is quite controllable. I did it on a few really bellied chisels, creating a bit of a hollow where a belly was. They have polished out, you would never tell there was spot grinding

I've done the same thing. You end up with a back that looks like a crude Japanese chisel. It's ugly, but it works just fine.

Lataxe,

One of my neighbors, a mechanic and machinist, says he does have a surface grinder and offered its use. It's not perfectly clear to me if I'm fighting chisel belly or hollow near the chisels' tips so I'm first going to try the coarse side of the stone for a reasonable amount of time and if that doesn't do the job then I'll take up the offer from my neighbor.

Thanks you.

" It's not perfectly clear to me if I'm fighting chisel belly or hollow near the chisels' tips "

A concave is easily dealt with but, a convex (belly) generally has me moving to something else. Are you saying that when you perform the flattening operation the middle of the steel is effected and the outer edges are not?

Are these vintage chisels or the recent re-release of the 750 sweethearts?

GeeDubBee

It seems to be a bit of both. On this chisel (3/4") I've probably put in something like 5 hours of flattening on the 1000 grit and I've made progress from where I started but my experience is that last little bit of flattening can take as long as the hours you've already put in. It's tough to photograph this stuff but I've roughly indicated the "still to be done" parts with the red lines.

The right side of the chisel back has been touched by the stone except for a roughly triangular area on the right corner, I'm 1 - 2 millimeters away from the bulk of the cutting edge, then the left corner and left side are still to be flattened. So maybe you'd call this "hollows" instead of "belly?"

_MJ_

These are the newly released chisels.

Bellies stick out. Hollows are innies. This is a belly.

Hollows are fine. Japanese chisels have immense hollows built into the tool. It's just the edges that need to be flat and polished.

As you can see, bellied chisels are a PITA. If you are in a store, check the backs with a straightedge. Never buy one that's bellied.

Diamonds are slow. They will cut pretty much every steel (with a few exceptions) and they will cut pretty much forever, but they're damn slow. Get some 80 grit PSA sandpaper and something reasonably flat, like thick glass or a tile, you'll be done in an hour. Just remember you don't need to polish the whole back, 1/2 - 1" is totally enough.

For me, "barely out of square" for a chisel is square. I cannot image a circumstance where that level of out of square would matter to me. Also the fact that the secondary bevel is not parallel along the edge is irrelevant. The wood does not care about the cosmetics of the chisel.

Tgy,

As you've discovered the hard way, not only is a bellied chisel back difficult to get flat - it takes an age, because you have to remove ever-increasing amounts of metal if and when you do manage to increase the flat area.

I'm afraid that you've been sold a TSO - a tool-shaped object. A bellied chisel new from the manufacturer is not fit for purpose and should be returned. It's one thing to polish an already flat back free of a few fine grinder marks but as your many hours rubbing have already shown, that chisel you bought is not yet a chisel. It'll likely take several more rubbing hours yet and may never come right, even so.

I suppose you could use a surface grinder to eventually get the back flat. If so, send the bill for all the time, electricity and work to Stanley. It'll likely come to rather more than the price of their TSO.

Many current manufacturers make proper chisels with already flat backs or the slight concavity that makes it easy to get them working in a few minutes rather than hours. There are expensive ones such as Veritas & Lie-Nielsen but others just as good functionally from the likes of Illes and Narex.

Stanley (whoever they are now) are trading on their name and that of once very good tools (the original sweethearts) but are selling what is often dross. And they aren't inexpensive either. Shame on them, whoever they are.

There are many reviews of tools, including some from those that can be trusted (FWW generally being one-such). It's worth reading a range of reviews for tools rather than believing the adverts and their glamour, especially the annexation and suborning of once-good trade names along with a spurious appeal to some sort of patriotism. (Buying American-made dross won't stop it being dross and merely encourages the dross-makers to make more dross).

Lataxe, on a high horse. :-)

Lataxe,

Unfortunately, since I inherited these chisels returning them simply isn't an option.

I have purchased a nice set of Narex chisels - not cheap! - but wanted to gain some experience flattening and sharpening chisels before I started on the Narexs. Most reviews of the Stanleys have been complementary and I inherited the complete set of chisels in the tool roll, only a couple of which had been touched by the owner, so I started in with those.

I'll probably at least try working one or two chisels on the coarse grit - at times I can be incredibly stubborn (or stupid) - but I may have give up on them entirely.

I have the same chisels you have. I find them to be better than Narex -- better steel at least. I've also found that people worry way too much about sharpening. The first half inch of the back needs to be flat to start with, even less. Over time, as you freshen the chisel, you will make more passes on the back and more will flatten.

On smaller width chisels, under say, 3/8, it isn 't always easy to get a perfect primary or secondary bevel. The side bevel of the chisel is a more substantial part of the width on a narrow chisel, which is part of the problem. But as long as you have a reasonably straight primary and secondary bevel meeting a flat back at the edge, all should be good. Cut some wood!

Sir Lack,

I can't agree with your notion that a (bench) chisel needs only the first half inch of the back to be flat. Bench and paring chisels are generally used with the back jigging the tool to guide the cutting edge planar to what the chisel back is resting on. You generally need far more than half an inch of flat back to do that jigging properly.

Perhaps you mean that only the first half inch of the chisel back needs to be polished or made flat without scratches or other roughness? That's true, as the shiny-flat end is the area where the edge is formed and so needs to be not just flat but free of scratches if a good edge is always to be obtained when sharpening it. Even 1/8th" polished back at the edge is enough - although harder to polish than half an inch, perhaps, as it would keep slipping off the edge of the sharpening medium as you rub.

The rest of the chisel back still needs to be flat even if not polished - still scratchy-looking. As long as all the back-area lies flat on the wood surface being used to jig it's edge to pare the work, polish isn't needed.

Even a concavity in some of the chisel back is OK, as long as the edges that delineate the back are flat (co-planar) with the polished area at the edge. The co-planar edges of the back will still correctly jig the chisel.

A belly or convexity in the back makes it near impossible to jig the chisel rightly. It will rock on the high point of the belly as you cut, resulting in a less than fair result.

Lataxe

I hollow grind all my chisel bevels. It really helps establish a nice square edge and a consistent angle as well as speed up sharpening.

I don't use jigs, but I think the principle still applies.

Yeah, I have been known to take a chisel to a belt sander.......

If the backs are that bad, you may have a bunch of glue removers there.

@TGY... You didn't know you would open a hornets nest here. There are as many opinions (Recommendations) as there are woodworkers. Sharpening has to be done right. You and only you can determine how far back the back needs to be flattened. However to more of the back that is flattened the better. Take them to your neighbor and let him get the backs flat. Then polish the back to remove the grooves so that your edge is clean. Use a magnifying glass to make sure the grooves won't be a factor on the leading edge of your chisel and then practice sharpening them by hand. Remember only the leading edge does the cutting. There are a couple of thoughts on "Primary, secondary, and Tertiary". But if you once get this part right you will take your woodworking to a higher level. Try watching this video from Dr. Cosman on sharpening chisels, https://www.youtube.com/watch?v=FIMx5HWLHdI. It's the best out there and will help you gain confidence

in sharpening. As far as the brand of chisel, the Stanley's are fine and you'll get a lot of service out of them in the future. Good luck. Using sharp tools makes woodworking fun no matter the tool. Saw blades, chisels, planes, drill bits are forever needing sharpening. Stay on top of these and you'll have more woodworking and less fixing and struggling. Once again good luck. You will look back at this in years to come and wonder "What's the big deal".

This forum post is now archived. Commenting has been disabled