Hello all,

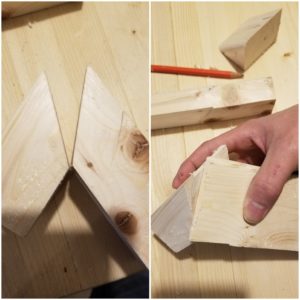

I’m a novice woodworker who is just getting into this hobby. I was wondering if someone can explain which direction is considered for spline grain to be perpendicular when making splines for a mitered joint. I understand that a perpendicular splines will make the joint stronger. I’ve attached some pictures. It looks to me like all of these are perpendicular as none of the grains are parallel to the cut. Which one would be considered perpendicular to the joint? Would one be stronger than the others?

Another question I also wondered is what force would splines help against. I’ve added pictures again. I’m thinking that splines would be strongest against the bending forces but not as much the twisting forces?

Thanks for all the help and guidance.

Replies

Splines serve two basic purposes, alignment and additional gluing surface. Extra strength is a result. Spline grain perpendicular to the joint will be stronger. However, as a practical matter, it really doesn't matter very much. In the situation in your photos, gluing the miter joint will be end grain to end grain and without the spline the joint will not be very strong. The spline provides extra gluing surface long grain to long grain which will be the strongest.

I'm with Bilyo on this one.

Nonetheless, this almost scientific video shows that splines really do add very little.

This is essentially because modern glue is so strong that the additional surface area is not especially important.

Thinking about the physics, the thinner the stock, the more relevant a spline is likely to be, but I have not seen this aspect testing.

Perhaps something FWW should get into?

@ben strano?

https://www.youtube.com/watch?v=SfyuCvrdvfU

The video that Rob included in his post is showing a different kind of spline it looks like to me. Is this what would be referred to as a key? Would a key be stronger than a spline?

To my knowledge, it is still a spline. The only differences are that his are inserted after the miter is glued and, as a result, are exposed on the edges. This is also generally easier to do unless you are using a biscuit joiner.

Perpendicular to the joint. Upper left of your first pic (and maybe others) is correct.

An article I read here says spline grain should run in same direction as the end grain.

Mikaol,

Which article you read where?

How about a plywood spline? Probably strongest. On the other hand, if the spline is a key (i.e. showing it's edges) plywood might not be the required look.

There are miter joints and miter joints. Some glued miters will be stronger than others, depending on the surface area glued, the type of wood, the type of glue and the nature of the stresses the joint will undergo. I spline or key all mine unless they 're the longer miters of corners in small boxes, also supported at the bottom end of the miter joint by a glued-in or on base, as well as by glued-in internal dividers across both walls of the box.

Even the small box miters might get a key or two if it will also be decorative in that box style. Why risk a glued-only miter joint when such joints may not be well-faced; or inclined to separate because of wood movement when the moisture levels change?

Lataxe

The wider the stock joined by miter joint (measured by the length of the miter) is the more you need the spline. As the stock moves, getting narrower and wider with the seasons the 45 degree angles actually change.

45s become more acute in the dry season and more obtuse in the wet season as the width of each board changes.

Failure is made more likely because BOTH boards in each corner are changing angles the same way, doubling the effective change.

I can count 19 doors from where I sit in my basement with this spline joint, that is 76 corner joints built in 2015 and no open joint to this date.

Gulfstar, who makes those clamps in your last photo?

I got them in an exchange with another woodworker. They come from the rotary clamping systems industry uses to assemble glued-up panels, they weight a ton but make a good base and of course can really put the pressure. Those rotary clamping systems are less used today so you can maybe find some dismantled equipment, Taylor use to make them.

I'll have to start scanning the auctions. They look awesome.

This forum post is now archived. Commenting has been disabled