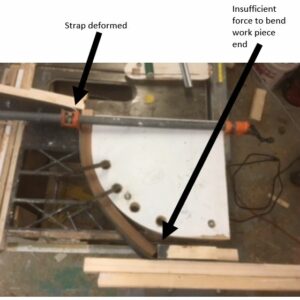

I am trying to bend black walnut piece (1.25 x 4.25 x 21) to a 13” radius, and my first attempt used the setup in attachment 1.

The result is in attachment 2.

If you have any advice on:

a) how to salvage this work piece (i.e., can I re-steam it once I correct my setup?), and/or

b) how to modify setup to avoid the described failures, I would appreciate it!

Replies

A couple of things to consider.

You need to allow for some spring-back

you really need a piece longer then final size

Once steamed, a second steaming is not always successful. Many times the lignin will not soften a second time

1.25 thick is bretty beefy. With the short end you have zero leverage. Build a form with ample "runout" on both ends and make the bend in a plank about 3X the length of the final part. EdWeber's point on springback is valid, especially in a thick part.

Make the radius slightly smaller and the turn longer to allow for it. If your finished part is a 90* bend go at least 10* more to start.

Start clamping in the center and have a helper to keep the clamps balanced and speed things up. Masonite under the steel strap might help things slide easier.

I think that your first workpiece is done.

I agree with EdW. First piece is toast.

Use end blocks that are denser and less compressible than pine.

Have the end blocks the same thickness as the walnut.

Have the walnut longer than the finished piece. At 1.25", you will not be able to get the last part to conform to the curve.

Extend your form at the beginning with a straight section so you can clamp the end block and band to the form before starting the bend to prevent blowout.

To repeat EdW, if you haven't already planned for springback, you need to. There is no way to know how much will happen except to try. You may get some information on it from the failed piece, in the section where the bend was successful.

When steam bending to such small radii, it is best to assume some failures, so be ready to use extra pieces.

Good luck! I hope this helps (and others may add further assistance.)

Agree with everything. Longer piece,, slightly over for spring back. Slippery surface etc. I often use polycarbonate. I don't completely agree that 1 1/4" should be difficult. Possibly longer in the steamer. This is steamed in a Box I am assuming? Faster work time. I have on tight curves made both sides of the jig and sandwiched the piece in between. Have on occasion actually built a press. Depending on what I'm trying to achieve I sometimes make a jig out of a series of pegs. I've never used pull ties, never even thought about it ( though I might sometime since I acquired some super ties from a linesman) but I have used strap clamps. Both methods give even pressure. I have found with some woods ( like redwood)that they can tend to want to cup. The thinner the material the more likely that that can happen.. Even pressure across the whole surface prevents that.. I have found with steam benting wood you need a set up that is very fast- no fumbling! If you have extra material do a dry,so to speak, run. How long in the steamer is long enough? Is your clamping set up good to go? Is the finished piece actually what you intended? Every type and even every piece of wood is different so calculating spring back is just a guess based on trial and error and experience.

That's a thick piece. I'd probably bend two thinner parts and laminate them after.

If I was bending it solid, I'd make a male/female square or rectangular form and use clamps to bring the form together.

Always bend longer pieces and trim when it's dry.

Wood is funny. Sometimes it springs back after bending. Just as often the curve will actually tighten a little, rather than springing back. It's counterintuitive, but real. And there's no way of telling which will be which.

You could bend to the desired radius the first half so there is no reason it could not bend fully other than the method used. The pine stoppers at the ends are complicating things. The bend normally starts from the center so I would cut a flat at the pointy end of your template and use the pipe clamp first to hold the piece and the strap at the 45 degree (center) position. Then you bring both ends progressively with c-clamps or a pair of pipe clamp at both ends.

Thanks to all for the advice. I think I managed to save the first try -- steamed it for 1.5 hours, added a support on back of strap at the non-lever end (to resist the strap bending failure in the photo). Result was much better, but still not completely bending on the ends, so will do as suggested re: longer blank and more complete circle as a form.

Thanks User-4102927 and all you respondents! I don't have experience in steam bending (I would have done this part as a bent lamination), but am thinking about it so I'm learning a lot from this discussion!

It does seem to me that bent lamination is easier and less fraught with uncertainty and trial in error if one is making a few bent parts. If one is going into the production mode, steam bending seems maybe better once the set-up is dialed in. Some advantage goes to the intact grain pattern of the steam-bent part, but bent-laminations are pretty too, and amazingly strong.

“[Deleted]”

This forum post is now archived. Commenting has been disabled