Strap Clamps on Box Joints – Got Tips & Tricks ?

Following up on previous forum advice I bought two Bessey strap clamps to reduce my anxiety when gluing up boxes. Previously I had been using regular clamps and pawls, but they were a pain to use and adjust. They also so cluttered the assembly that I had a hard time getting to the inside to clean up any squeeze out.

I tried the new Bessey clamps today; first on a “note pad” size box and then on a second, taller box. The shorter of the two could accommodate the angle fittings supplied with the strap clamp and I only needed one strap to cinch it up well. It was little tricky to get the plastic corners in the exactly the right place, but much easier than dealing with multiple standard clamps.

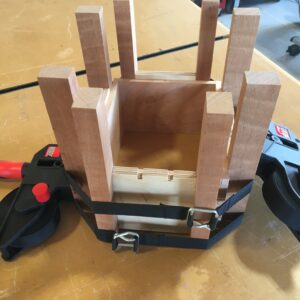

The second box was a different story. The the material was thicker, the plastic corners would not clear the tabs of the finger joints, so I reverted to using some pawls I had lying around. When I tried to tighten the strap, the pawls kept being pulled out of position, mostly in towards the center of each side. I cut some scrap plywood and slipped it in between the pawls, and that helped greatly in keeping the pawls in control and away from the outside corners of the glued up box. The second box height needed two straps, but with the pawl & spacer arrangement, it all worked well. Again, much easier than multiple clamps…

BUT !…there must be a better way to deal using the strap clamp on small boxes ! Does anyone have tips of tricks to suggest ?

Replies

These might be useful: https://www.rockler.com/box-joint-cauls-box-joint-jig-cauls-sold-separately

Stop using clamps.

What?

It's a box, not a chair. Even an unclamped finger joint will be way more than strong enough. As long as you can get the joint closed (therein the problem of course) clamps are not required unless using polyurethane glue.

When dealing with thin stock and good, tight joints, the point of failure is not going to be the glue joint.

Agreed - to a point. Some finger-jointed corners will have a tendency to want to leave a wee gap because the sides involved have a weeny bit of warp in them. A clamp will squeeze the last millimetre of gap together.

For fingers that are less than 8mm wide, an F-clamp or three, strategically placed, can span any finger ends that jut out, to squeeze the box sides just enough to close any teeny gaps. For larger (wider) fingers, these Japanese clamps can be got between any fingers to squeeze specific gaps together.

https://www.fine-tools.com/hatagane.html

I like those small clamps for all sorts of little jobs where there's a small gap that doesn't take much pressure to close but does need something in the way of such clamps, wiggled into small spaces to apply the pressure in just the right spots.

****

A band clamp is exactly the wrong clamp to use for finger joints that are made so that the finger ends are left proud - which is always a wise thing to do as it's quick to sand or saw-off finger ends whereas sanding a whole box side or four to bring them level with recessed finger ends takes ages; and reduces the dimensions of the box to a size it perhaps shouldn't have.

Lataxe

Just my opinion, but I need to use clamps to keep the box square, not so much to keep the joints tight. Things get slippery.

I know what you mean but .... one virtue of finger joints is that the joint itself incorporates a great deal of "square" so that if you clamp everything up tight (with the fingers well-made and a perfect fit ) this automatically squares the box in a way that some other corner joint won't.

Dovetailed corners should work like that too - but for some geometrical reasons (that I can't really figure out) squeezing even well-made DT corners together doesn't seem to automatically square the corners as it does with finger joints. You often have the clamp a bit across the corners to shove the carcass square.

It may be that DTs are more forgiving of a bit of imprecision in their making so don't necessarily squeeze together square when clamped; or perhaps it's to do with their sloping parts ...... I'm guessing. :-)

Lataxe

Thanks for the input guys. Let me try to respond to a number of them in more detail. (I didn't consider much of this relevant in the initial post !)

While now retired, I spent 50 years as a jeweler, the curse of which is that to my eye, a gap of .003" is wholly unacceptable. While I'm trying to work my way beyond that perspective in wood working, it's difficult to do. I'm making up a series of small boxes with scrap left over from various projects. Not so much because I have a need for a bunch of small boxes, but more as practice for what is necessary to know about the techniques to make them.

While I had seen those Rockler corner pieces, they are dedicated to standard finger joint sizes (ie. 1/4", etc). The joints I have cut were done using a Shaper Origin (sort of a hand held mini CNC router). I have cut a few finger joints in the traditional sled method, but was not greatly impressed with the outcome. Believe me, the jury is still out on the Shaper approach, but it allows precise joints to be cut with any number of tabs and using any width of material....hence the tabs are not "standard sizes" and would not fit the Rockler devices.

I see some type of clamp as necessary for the boxes. Not so much for a strong joint, but to take up that last fraction of millimeter and pull (and hold) the sides into square. I like the look of the small brass clamps and could see them being helpful in pulling the box to square from the diagonal.

Yet to try Dove Tails.....

I suggested this to a dovetail question.I have some 3/4 inch aluminum bars 6 inches long.On one side i drilled 1/8 inch (I think ??) holes 1/2 inch apart along one side.I insert those rockler plastic shelf clips in alignment with some or all of the dovetails (box pins) with the ends of the clips filed flat.A clamp on opposite bars for say ten minutes and you get tight joints. I have 8 of these bars and can clamp any box.Should get someone to make them.PAULS CLAMPS !

On small boxes I use big rubber bands! Get some latex tubing, about 1/4 or 5/16" OD and cut a piece about half the circumference of the box, and tie the ends together. You can then stretch this big rubber band over and around the box. For me, it works like a charm.

This forum post is now archived. Commenting has been disabled