Hi All,

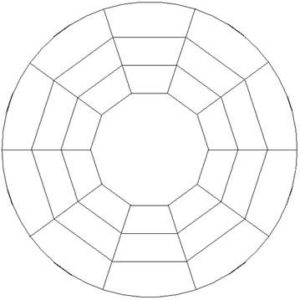

I want to build a dinning table whose top is pictured in the attachment. The top will have diameter 5 feet. The center decagon will be ceramic tile on a plywood base. I am asking for advice on how to construct this top. I thought I would glue up ten panels, cut out the wedges, then join the wedges with splines. Then using a router on a compass, cut the outer edge circular. Does this seem reasonable? I was planning to use oak. Do I have to worry about wood movement? Any advice on how to glue the sections together?

Thanks for your time.

jt

Edited 7/12/2007 3:27 pm ET by tomberg

Replies

Hi Tomberg:

Your strategy seems perfectly reasonable: Edge glue the boards to create the rough panels, then cut them into your wedge shape, then join them with biscuits or splines.

If you use biscuits, make sure you identify the final circumference of the tabletop so that you don't have a biscuit slot landing right on the line.

In thinking about the final glue up I'd try two approaches. One is to glue up all the wedges in stages so that it's more manageable. The other is to use a slow-setting glue and assemble the whole tabletop at once using a strap clamp around the perimeter to drive all the parts together.

You don't have to worry about wood movement here because all of the wedges will be moving in unison.

Matt Berger

Fine Woodworking

I'm going to contradict the other postings, there is a definite problem with wood movement here.

The wedges will be expanding and contracting from the center outward which is the across the grain direction. The wedges won't be expanding across their width. When one dimension of a triangle changes but not the other, the angle between the base and the sides must change and the seams will either open up or the wood will crack. This is a classic problem with conventional miter joints but it still applies here. Bruce Hoadley devotes a page or two to the problem in "Understanding Wood".

My intuition is that the problem will be less pronounced at each seam because it is spread over more joints, but I'm not sure of that, and the large dimensions of the wedges will generate a fair amount of movement which will make the problem worse.

This is an excellent application, as already suggested, for veneer.

As to the glue up for this type of table here is how I would do it:

Glue up the segments in two half sections so that you have two semicircles of 180 degrees each. Then adjust the join between the the two halves until you have a tight joint and glue the two half circles together.

John White

Edited 7/14/2007 9:46 am ET by JohnWW

I agree with John regarding the wood movement issue- also in a joint like this you are essentially gluing end grain- which means you definitely need splines. But even then- the length of this joint is what will give you the problem in solid wood. The coffee table picture you posted has the perimeter piece only about 3 inches wide which means the actual joint is only a little longer than that- On a five foot diameter table the joints will be MUCH longer and (even if you get them perfect now) will eventually open up for the reasons that John pointed out.

Using veneer will solve these potential problems.

Let us know how you make out.

Bob Van Dyke

Thanks for setting me straight Bob. After reading through all these posts I realize that I totally oversimplified things. Veneer is a great idea here.

John, Matt and Bob,

I was worried that since the wood would not move radially but perpendicular to the edges the joints would push apart. I guess I need to either review back issues of FWW for articles on veneering or change the design. Thanks again for taking the time to help a beginner.

jt

Edited 7/16/2007 9:49 pm ET by tomberg

Tomberg

I agree with Matt's answer for you tabletop- in theory! The problem I see is that it will be very difficult to get those angles exactly right- any deviation or discrepancy in the angle will compound with each additional wedge. I would seriously consider doing this top in veneer on a stable substrate like MDF. As you are adding the wedges you can re -shoot the joint with a plane to get them all to meet up with no gaps.

Bob Van Dyke

Thanks Bob,

I agree completely with your thinking about a slight error in the angle compounding around the table enough so that the last wedge will not fit. My plan is to cut 9 of the sections as close to 72 deg as possible, put them to together then measure and cut the last section to fit. With some luck it will be close enough to the others to be not noticeable. Attached is coffee table version of the table. (Tiles have not been set.)

Thanks again for your advice.

jt

This forum post is now archived. Commenting has been disabled