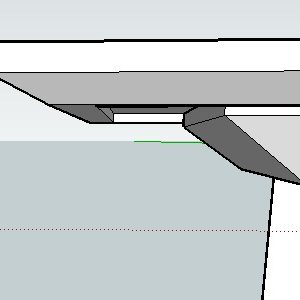

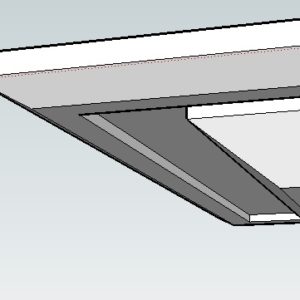

I am getting ready to start a large table top and as part of the design I would like to hollow out the underside of the table leaving a 2-3 inch wide lip around the outside bottom of the table so it will overhang and help conceal the skirt a little bit. Basically what my concern is that when I remove the material on the bottom it will cause the wood to move. Im looking at about a 1 1/2 inch thick top with about 1/2 inch of material removed from the underside/middle. So im losing about 1/3 of the wood over a large area of the table top. See attached images and hopefully what i have said will make more sense.

Discussion Forum

Get It All!

UNLIMITED Membership is like taking a master class in woodworking for less than $10 a month.

Start Your Free TrialCategories

Discussion Forum

Digital Plans Library

Member exclusive! – Plans for everyone – from beginners to experts – right at your fingertips.

Highlights

-

Shape Your Skills

when you sign up for our emails

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. -

Shop Talk Live Podcast

Shop Talk Live Podcast -

Our favorite articles and videos

Our favorite articles and videos -

E-Learning Courses from Fine Woodworking

-

-

Fine Woodworking New England Event

Fine Woodworking New England Event -

Replies

If I understand, you're

If I understand, you're concerned about what happens when you remove a lot of material from one side such as when resawing or planing and the imbalance of moisture causes the board to warp, right? How is the top made? Is it one board or several narrow ones glued up? Quartersawn or flatsawn? How well seasoned is the wood?

If you've already got a lot invested in this project and can't afford to risk something funky happening, I'd suggest removing a little material (1/8-1/4"), then waiting a few days before taking some more off. Just my thoughts here.

Chris

Yeah the warping is exactly what im worried about. The top is basically two equal sides made up of Is 8/4 walnut between 3-5 pieces (left and right) that will open up for a 20 inch leaf. I am looking at pieces 1, 2 and 3 for the top.

As far as the wood im getting it from a small lumber yard who specialized in large book match slabs, Its more flat sawn as it is a few slices away from the center fitch of the tree. But this wood has been well taken care of and i feel its overall very stable. This is a personal project so i have no problem taking off 1/4 inch and letting it sit for a few days and going at it again.

Remember that the wood has to acclimatise to your home/shop too.

Hard as I try I can't figure

Hard as I try I can't figure out why you want to go to so much trouble in the first place.

Why is simple. Because the look I want needs the top to overhang the base about 1/2 inch. If you have have a better way to accomplish this I am all ears.

In your initial SkethUp drawings, it does look sort of cool, but isn't there some sort of law against looking up a table's skirt? ;-)

I guess what I'm saying is that from the angle most people would be looking at the table, the overhang won't be apparent. It will likely be lost to all but those who use it to dispose of their bubble gum at the table. ;-)

Yeah true but the farther away you get the more you see under the table, as well as when your sitting in our living room your right at the same hight as the table.

Believe me if there was a easier way to do this i would give it a shot for sure. And if i catch someone sticking gum to the bottom ill take em to the shop and show em some of the nice power tools that where used to make it, if you know what i mean.

You can add a molding instead of cutting away material. Your drawing shows you plan to undercut the edge with a chamfer. You could hide the edge of the molding where the chamfer starts.

I know, it’s not one piece… But what do you do if it warps?

Doug

Doug are you thinking to glue long strips down the underside of the edge? Wouldn't this cause issues with the grain running at a 90 degree angle to the top slab.

I thought this morning that I should have said somthing about matching grain direction with the molding. If it's end grain along part of the table, then make a chamfer molding using end grain wood for that part of the table. It will be small pieces, but since you said it will be a 2-3" wide lip, you have enough glue surface to hold the molding in place.

Doug

Yeah this would work. It would be the same wood possibly even the matching cut off's for the ends so movement shouldn't be an issue.

You're a step a head of me.

You're a step a head of me. I hadn't thought of the cut off pieces for the molding. That's a great idea. It will give you the match you are looking for in both grain directions.

Good luck with your project!

Doug

I just finished a table top similar to what you described except the ends project 8 inches. The taper is from 1 1/2" to 3/4" at edge or the thickness of 4/4 board. I found it easier to cut the tapers from a smaller boards and glue them to the top than running the entire table top through the saw. I used a drafting program to figure out the angles I needed to cut the proper slope and more perversely how to get both sides from cutting a single board. Ripping the pieces wasn't actually a single cut because I had to flip the board end for end to have the second meet the first and end with two usable pieces.

One side was glued to the bottom, then the end pieces and finally the other tapered side. The tapered pieces were oversized and I planed off the corners and faces to fit. The pleasure was in dropping the top over the cabinet and hearing this clunk as it settled into place. It covers the joint between table top and cabinet, but in reality few people will every notice that or the tapper below.

Good thinking, I like it, and I Love that you displayed it on your bed for the photo. Awesome!

Wisky,

What if, instead of removing all that stock (I think I understand that you want to remove 1/2 of the face of one side except for 1-1/2 inches at the perimeter.) you only remove that 1/2 inch in the area where the table bottom will be exposed, plus the thickness of the apron, plus around another 1/4.

Instead of turning the underside of the table into a shallow bowl (saucer?) you will have something like a mote. Most of the stock will be retained for stability and you will still get the effect you want.

Of course, you will have to allow for this in any structure inside the peremiter of the aprons, but that should be easy enough.

Frank

Frank The table top is going to expand and if i only hallow out an area so it sits down over the base then when it goes to open the material that has been left in the middle will hit up against the inside of the base. Does that make sense?

How about a fixed top and a movable base for expansion?

Frank

If you are still committed to hogging out the bottom of the top why not just trace out where the legs touch the bottom and just route out those areas? Then you end up removing less material thus reducing the risk of warping. Otherwise I recommend not doing it.

The wood top is going to move, period! So relieve the ½” from the bottom, and flatten the top afterwards. A one inch thick solid wood top is sufficient for a dining table so long as it is well supported by the base. Be sure to allow for wood movement when attaching to the base. Good Luck!

Typically, in architectural woodworking, what you would expect to see in this situation is the outside board treated as a nosing. Make the perimeter the thickness you desire, and let in or bisquit, the top (milled down to the thickness of your choice) into the edge or outer board. This will allow you to purchase 5 or 6/4 for the perimeter and 3 or 4/4 for the field. Tenon the top into a mortised bread-boardend, and you're golden.

LouK, AIA

This forum post is now archived. Commenting has been disabled