Taking advantage of lowest areas under sloped ceiling; Laying out new shop in 2nd Story over Garage

I am working on finally turning my second story loft space over my 2 car garage into a legitimate workshop. For the past 7 years while I’ve been rebuilding and remodeling, this space has been relegated to material storage (piles and piles on the ground!!).

Its time to make it a functional workshop so I can get back to hobby woodworking instead of remodeling the house.

The space has a ton of potential:

The garage is an oversized 2 car – about 30′ x 24′. There is no first floor access, but it has a set of (nearly) code compliant stairs as well as a hoist beam & 5’0 doors at the gable from driveway for lifting materials / tools in. Not ideal but it works with a chain hoist / pulleys & pallets.

The roof framing is 10 pitch with no knee walls above the deck; so I am left with sloped ceilings (10′ height for about 8′ under the collar ties all the way down to 18″ at the edges.

I am struggling a little with trying to take advantage of the space, especially the low areas as the sloped ceiling approaches the floor.

I don’t want to put up new knee walls every where and block off 4′ or so of accessible storage area to get good walls with 5-6′ of head space.

But I have almost no wall area since the two gable ends are taken up by the double door access on one side and the stair on the other.

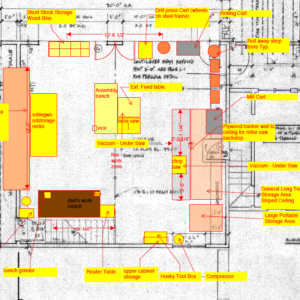

I’ve posted a picture of the floor plan (actually first floor garage plan overlaid with my starting layout – I don’t have a second floor plan in the architectural drawings. Also a couple pics of the stuff I’ve been dumping in place.

I have been in the construction business for 25+ years. Started as a finish carpenter / cabinet installer / remodeler; then transitioned to my own building company doing larger and larger scale mixed use multi-family over the last decade +. Being semi-retired / out of the day to day contracting business… I have a TON of tools that I can’t part with. Lots of jobsite finish carpentry tools, but also heavier construction tools that I want to store but won’t really be used in the wood shop. But I like having them around 🙂 Long term I want to upgrade some of my job site tools for shop tools – table saw is number 1 priority. So I am going slow with building customized cabinets etc. for tools I may replace. You may see vaccums listed on the plan – I am planning to use the multiple shop vacs I already own as de-centralized dust collection for now; long term adding dust collection is in the works but I need to nail the layout before I can even consider this….

I also need to store a ton of hardware / fasteners / (admittedly alot of heavy duty anchoring hardware I’ll probably never use again… but I can’t throw it away. I’m a old yankee at heart…

I also am trying to do this on a budget taking advantage of all the salvage stuff I have from over the years of doing construction work. I just cleaned out my “work” shop and have a trailer load to start organizing an adding to the space. Ideas on the slopes would be appreciated!! Everything in there now is salvaged. I also have my dad’s / grandfather’s old work bench that I was able to relocate up there – not a wood working bench but very sentimental to me.

Thanks,

Replies

Have your thought about really long sliding drawers or shelves. It sounds like you need storage for a lot of stuff you don;t plan to access very often. 3-5 foot sliders might work for you.

Thanks for your comment - I think that's a great idea. Given alot of the stuff that I need to store but not access very often is very heavy, I am thinking maybe I do a system of sloped "bins" on heavy casters that can be rolled out and stowed away behind the tools that are used more often? Almost like drawers that glide on the floor? When they are stowed away it could look like a plywood wall with big drawer handles.

Has anyone seen pictures or shops that have used an idea like this?

Would it work to build a series of "carts" that have one vertical side that could be wall storage and whatever sort of bin/shelf/anything else configuration on the back side? You can slide the carts vertical-side out into the overhung area and you have what amounts to a temporary knee wall that gives you storage space, but you can move them if they're in the way or pull them out one by one to gain access to the deeper storage that's on the back side. You'd be somewhat limited in the size of each module by what you can turn around or maneuver in your space, I guess. And there is the constraint of the cost of casters, though the house-brand moving dolly from Northern Tool is quite cheap and can be had even cheaper with their pretty solid coupon program--you can always harvest the pretty decent (non-locking) casters from those.

One would hope you're taking into consideration the weight of everything. What's the load carrying capacity of that floor?

i'd consider a bandsaw instead of a table saw, but depends on what you are making. Also if you are going to make more furniture-y stuff, then you will want a workbench as the central fixture rather than the table saw.

i was just looking at my porter cable 126, 314 and 4x24 sander and some other vintage tools, wondering the last time i turned them on. Hard to part with, but that's nostalgia more than anything. i'd store the builder items away from the woodworking shop - they are almost apples and oranges. just a thought -- and another reminder to practice what I preach.

@moonshot - great idea with the carts that can double as 'knee walls'; i'm finding I am lacking in usable walls to store regularly used items with all the slopes. Casters is one thing I have no shortage of in my old job site supplies... I have bins of casters & site built dollies saved from a delivery of grocery refrigeration equipment from a project I did years ago - every 4-500 lb case came on steel hss mounted casters as the shipping method.

@stamant Definitely a band saw is in the plans as a purchase in the near future - I don't currently own one but I was thinking it would be on casters and able to be moved around the shop. And your point is well taken -many of the 'builder items' would probably be best stored elsewhere but I don't have room in my main garage level for it all. Its hard to know where my projects will take me long term, but I see a lot of custom cabinetry & shop furniture on my plate for the foreseeable future while I try to get this all in order. I think the table saw / bench combo will be my most frequently used station for a while.

Thanks for comment on the weight, but the floor is not overloaded by any means. The new table saw will be the heaviest concentrated load PSF; with 2x10 DF framing at 16OC, I am well within acceptable loads, and the heaviest items (besides new table saw) are distributed and stored at the perimeter (where the ceiling is low) providing nearly direct transfer to the exterior bearing walls.

How about two sets of sliding doors to create a sliding wall? Two of those doors could also be used to hang various tools. When you need to access the storage behind them, slide a door over. This can also help limit dust accumulating behind the doors. Anything not in a drawer or behind a door inevitably gets covered in dust, at least in my shop.

I’d consider installing two vertical triangular walls to the left and right of your current long stock storage. Notch the top to store the long stock near the roof and add cubbies for small stock to combine all your lumber storage. In the freed up space by the door swing, you can add a future band saw.