I have some old hand planes that I decided to try to start using. I picked them up at garage sales years ago and never really used them. So I started restoring them. One thing that’s been consistent for me is having trouble getting the back of the chisel plant flat all the way to the end of the cutting edge of the blade. I’m not trying to flatten the entire back – just within a couple inches of the cutting edge. I

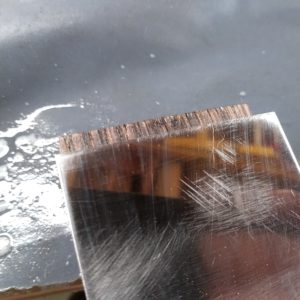

If I orient the chisel perpendicular to the long edge of my diamond stone and move the chisel back and forth along the long edge of the stone, I have trouble getting it flat up to the cutting edge – maybe a mm or so at the edge doesn’t seem to get flat – looking at cutting marks (using 300 grit to start with). (See attached photo)

If I orient the chisel in the same manner but push the plane into and back out of the short edge of the stone, I can get it flat all the way to the edge (hope that makes sense between the two sharpening methods).

I’ve seen it done both ways in videos but have no idea why I have such a hard time getting the edge flat doing it with the first method. I feel like I’m pushing down plenty firm using both methods.

Any thoughts would be appreciated.

Replies

If it flattens to the end by using the alternate method then that indicates a technique problem assuming the plate is flat. Maybe pushing down too hard. If you are pushing down close to the edge of the plate maybe you are lifting the plane blade end slightly.

Is it a good quality diamond plate?

Nice shine you have there.

The problem seems to be that the parts that are dull are not in the same plane as the parts that are shiny.

There are at least 2 different grit marks shown and they are in the same place, so it is probably not anything wrong with your stones.

If it is working pushing in and out, then do that, but it is hard to explain that pattern with any technique issue.

It is much more likely that the back was not fully flattened on the 300 grit stone.

I've chased those corners forever. Now on new (old) irons once I get to about where you are now I just grind back past them... or just get a new iron.

I noticed in your photo that your sandpaper looks like it’s not sitting flat and that could easily cause you to inadvertently round the end over.

Here’s the way my instructor taught a class of 25 new-to-woodworking students.

Make sure that paper is flat, apply even pressure amongst all of your fingers across as much of the width of the blade as you can, and then lock your body from the shoulders down. Rock back and forth from your heels to toes.

This gets good results because you have eliminated as much human error as possible.

I know how frustrating this can be but hang in there because you are almost there and it will be worth the effort.

Make sure the stone or plate is flat. This would account for what you're seeing.

I've been surprised more than once.

I flatten with blade perpendicular to stone, except on chisels narrower than 1/2". It can also have to do with finger pressure, but it sounds like you're doing it right.

Thanks for all the feedback. The plane blade in my first post was done with sandpaper on glass. A couple days ago i got my new diamond stones in the mail. I tried with them with high hopes and initially got similar results. Then I started applying a little upward pressure with my left hand while pushing down on the plane with my right hand. Just enough pressure to help keep the blade flat on the stone with my right hand. This seemed to help. I also tried the rocking method locking my body.

You can see in the attached file that I got it flat to the edge - still have that corner to work on. I created a jig a couple weeks ago to help hold the blade because my fingers got tired after spending so much time flattening. That helps as well.

I'm using 300, 600 and 1200 grit stones. I'm trying Paul Sellers method of free handing a concave bevel - seemed to work ok - I don't have a strop yet so hopefully that will help get it to the next level.

Would be nice to have an instructor there to show my what I'm doing right and wrong, but I guess I'll eventually figure it out. I did use one of my sharpened planes to refinish the top of a dog dish table I had made years ago. Originally I was going to sand it, but thought, what the heck I'll give my plane a try to see if I could have any success. What a joy it was to get some nice clean shavings and a smooth top. And I"m sure by sharpening can still improve a lot. Much more pleasurable than a loud sander and dust flying everywhere!

This forum post is now archived. Commenting has been disabled