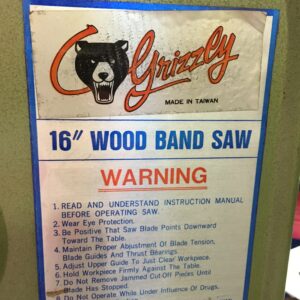

Recently found a 16″ Grizzly band saw and I’m in the middle of tuning it up.

1) How much is this used saw generally worth? Guy seemed knowledgeable and said it had a really good motor.

2) What does the bearing above the two guide bearings do? Doesn’t seem to touch anything.

3) Guy said the thermal overload dial should be set according to certain parameters but I’m not sure what they are.

4) Any clue about it’s model number? All I could find was the sticker stating 16″ band saw.

5) The bottom wheel has some play in it so I need to replace the bearing. Any advice on replacing it? Doesn’t seem like a socket has enough room to fit over that nut.

Replies

“[Deleted]”

That's a lot of questions in a single post. I would suggest for clarity you repost them as separate questions.

In the mean time I will answer the questions I can as best I can.

That appears to be an early model Grizzly (notice the Grizzly sticker haphazardly applied over the original) made when the tools were of uneven quality even more so than today. It's value lies with the buyer but I would not pay more than $500 for it if I knew it was running. (you shouldn't ask this question on something you have already purchased)

The bearing above the guide bearings is called a thrust bearing and should be adjusted so that the blade only touches when you are actually cutting wood. The picture shows none of the bearings properly adjust for the installed blade. I suggest you search FW for articles on setting up bandsaw.

They probably used a thin walled socket to attach the lower wheel so your only solution would be to grind the outside, of the proper socket, down until it clears. Although there are some sources for thin wall sockets, mostly I've seen them for wheel lugs but it's a long shot to find the right size.

Too many questions

The belt is obviously too long as the compressor is currently configured. The notches are fine notches perpendicular to the the edge are for flexibility, notches parallel to the edge are for increased friction and bite when couple with the proper pulleys. You do appear to have the belt inside out though, the notches should be against most of the pulleys.

If you are reasonably certain that you have the correct belt for your machine, I can't help but notice what appears to another mounting lug above and to the right of the current location of the tensioning pulley. When you buy used machines you never know what modifications a previous owner may have made and if it was me I would see if the tension pulley could be relocated to that point and if that takes up the excess slack. Your belt routing seems correct, just inside out.

check the back of the cabinet behind the bottom wheel. There might be a set screw holding the axle in place. I'm betting the screw on the wheel wasn't meant to come off.

Why not send this same info to Grizzly and see if they can help you?

The issues you describe plus the aluminum wheels would have me walking away. I would not be surprised if you have to change out the upper and lower guide and thrust bearings, they look pretty crusty. It looks like it's been sitting for a bit; did you see the saw run and make a cut before you bought it?

esch5995 thanks for all the advice. I figured out my belt questions right after I made my post and deleted it soon after, but yes you're right that was a lot of questions. With all it's potential problems I'm glad you have valued it fairly well. I paid $235 with the idea that at worst I could get my money back out of it. I gave it a good once over and made some cuts before we did the sale, although I traveled about 4 hours to get to it so that was a bit of a risk.

MJ thanks for the advice to contact the manufacturer. Never thought to give them a shoult but I'm sure they'd have good advice.

By all means call Grizzly. I bought a 14" Craftsman bandsaw which seems to be branded by numerous companies including Grizzly. I ordered several parts and they all fit. Points being that they were very helpful and that parts may be available from more than one source.

This forum post is now archived. Commenting has been disabled