Using top of grinding wheel?

Hi everyone greetings from smoky California. Since I can’t resume work on the cottage I’m building, due to the air outside being worse than a 70’s nightclub, I decided to get going on my DIY grinder project. I got the grinder part pretty good, but my Veritas grinding jig seems to be backordered for quite some time and of course I’m anxious to get started.

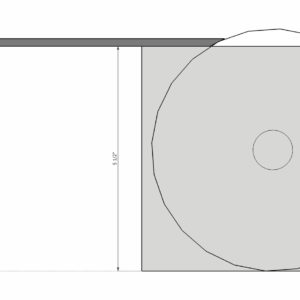

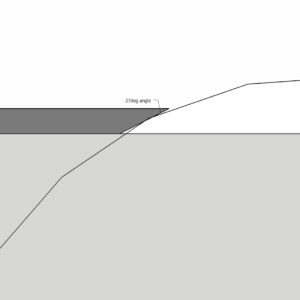

This got me thinking about makeshift jigs to hold my tools at the proper angle, like cutting a chunk of wood and screwing it to the plywood the whole contraption is attached to. Then it dawned on me that the grinding wheel being a circle, there must be a point where holding the blade parallel to the work surface would hit the wheel at the precise angle I want. If this is not news to anyone my apologies, a cursory search yielded nothing.

I decided to sketch it up to scale on sketchup and it seems plausible. All I need to do is make a box around the grinding wheel at the right height with a slot at the top for the wheel to poke up. I would make it a little lower so I can put a shim on top to allow for a chisel handle.

If this is a Darwin award in the making, please feel free to show me the error of my ways…

Replies

You are correct - good illustration. The goal is to get the middle of the blade in contact with the wheel. The thing a grinding jig does most is move the workpiece - the thing being ground - to a more comfortable angle. The way you have it pictured, with the top of the grinding wheel sitting about 44" from the floor while on a table or stand, your ergonomics are wrong. Rotate the contact point to the left (counterclockwise) about 60 degrees and you will move the cool end of the blade into a much more comfortable holding position.

Good choice with the Veritas. I have it, easy to use, sturdy. You can get replacement tops for it, which is good, because you will inevitably drop it into your turning grinding wheel while making a small adjustment. Don't freak out when that happens. All is not lost.

To get a particular angle on a blade, the tool rest must be at a certain angle to the grinding wheel. Since the wheel is round, that could be on the top, bottom, back. Wherever.

There are a few issues. If you have the blade on the top of the wheel as you show, the sparks are going to get thrown right at you. Not fun.

On a store bought grinder, there is a small range of the wheel's diameter that's usable, because That's where the guard is cut away. To use the top of a store bought grinder, you'd have to remove both the inside and outside of the guard.

Then there is the tool rest. To grind on the top of the wheel, the rest needs to be a lot taller. That would also make it less stable, in addition to being awkward.

CAN you grind on the top of the wheel? Sure. Geometry on a round object is very straightforward. But it just isn't practical.

There's a reason that every grinder made has the tool rest in about the same spot.

Checkout garret hacks videos using a homemade grinder tool rest that’s what I would do.

Thanks for the replies.

Woodnub seems to think it'll work but the ergonomics are less than ideal. If I put the grinder on a surface 6" lower than my workbench it would remedy that.

John_C2 apparently didn't read my post well. As I describe making my own guard that also acts as the blade rest. The sparks may be a valid point though.

I will take Muskokolayne's advice and see what Garret Hacks came up with. Though this whole experiment is just a down and dirty idea until my Veritas arrives.

Email The Philadelphia Workshop to see if the will send you their plans they use in a course they give .Their wood jigs work as well as any home made I have seen

This forum post is now archived. Commenting has been disabled