I’m about to start building two carts for my shop. I have precious little horizontal space in my machine shop, so the primary purpose of these carts will be material handling.

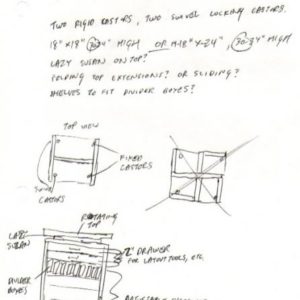

I made a few sketches last night and think I’ll build them 30″ tall, or so. I had originally planned to build them with a 2’x2′ square footprint, but now I’m thinking about 18″x18″ or perhaps 14″x24 or 18″x24″. I’m not sure whether to use two swivels and two rigids or four swivel castors. Brakes are a must. I’ve toyed with the idea of sticking with the lazy susan on top, but with four swivel castors may not be necessary. Two drawer inside at the top for layout tools, wrenches, etc and adjustable shelves below.

Your thoughts, gentlemen?

Replies

Well, I'm not a gentleman, but I'll share my first thought anyway: watch out for center-of-gravity problems.

FG

I'm a bit worried about that facial hair you seemed to have aquired lately

wot

Hi Chris

I have attached a rough sketch of one I made for my shop. Its designed more as a mobile workbench for those jobs you do all around the house. I think the size is about 2' x 3'. The top is more like a tray to hold a pigeonhole tray for all those nails, screws drillbits etc, on one half and the other for drills and other tools. A thick top is hinged over the pigeon hole tray side to use as a small workbench/top and the underneath is just another tray/shelf.

I added a double powerpoint and ext cable for power and I also have a small vise (the swiss army type, zylis I think), that I can clamp on the top.

Hope some of these Ideas give you more to think about.

regards

wot

Carts, due to the fact that they employ The Wheel, are great. I have a couple in the shop for moving stuff around - "store-bought" made of composite plastic (but, strong) material.

I agree with FG - center of gravity (i.e. anti-teetery-tottery) is important. I'd suggest a rectangular top, 18-24" wide by 24-30" long, one pair of fixed wheels, one pair of swivels. Four swivels tend to be difficult to steer under a heavy load. You can always "parallel-park" the fixed wheels into tight spaces.

I like having a tray-style top, around 3" in depth. You can add a flat top with positioning cleats on the inside to create a support/work surface, if needed. Or, a flat panel with rollers as an outfeed top. Thinking in those terms, design the cart height + roller top to be the same height as your saw, or a smidgeon less.

For an "open" cart, I like 3"x3" angle (L-shaped) corners for rigidity, bolted to the outside of the top and the inside of the bottom tray (forcing a tray-size differential to keep the uprights plumb. The joinery can be "fancied-up" as necessary.

I'd also suggest at least 4" casters, heavy-duty with rubber tires. Smaller ones are too easily twarted by a cord on the floor, or an expansion joint in the concrete.

Chris:

I'd build the cart so the surface is the same height as tablesaw, workbench, et cetera - you can slide heavier objects from one to the other. Mine probably are 30" wide so they'll fit through doorway, and 48" long. I have 4 swivel casters on each, don't find the cart hard to steer and it can make tighter curves.

In theory, locking casters are good (and I have them) but the cart is so light that it can slide across the concrete even with the casters locked.

I'll start with (2) 2x4x42 and (2) 2x4x21, on edge, assembled with drywall screws to make a box 42" x 24". Make a second identical box. The legs are simply upright 2x4's screwed inside the corners of the boxes. I'll add a couple 2x4x21 cross cleats to each box, then screw a piece of 48" x 30" x 3/4" plywood to the top. They aren't fancy, but have held up to regular use for several years. I've never considered adding drawers.

I could store materials on the bottom, but haven't very often. With a couple shelves, a cart might work well for holding all the materials for a small to medium job.

Chris, I was looking over your post. Wot, Ralph, and Don all have good ideas, like the inside storage, could be handy for current projects, and all so for storage of small cut offs that are always needed for supports or shims, as well as keeping the project in one place and out of harms way. garyowen

Ladies & Gents,

So I went

Ladies & Gents,

So I went ahead and built one cart today. I will probably build the second tomorrow. What you see below is the made from one 18" x 8' piece of 3/4" plywood and one 24" x 8' piece of 1/2" plywood.

I decided to go with a rectanglular footprint, 18" x 24". I sized the cabinet at 24-3/4" tall so that I could get a whole cart carcass out of one 18" x 8' piece of 3/4" poplar plywood. With 4" casters, the cart will be about 29" tall, and I can add blocks to raise it up higher if need be. I made the back and shelves and drawers from 1/2" pine plywood (both plywoods were the cheapest plywood at about $40/sheet - I like the pine because it has a decent-thickness outer veneer). The carcass is assembled with dadoes and rabbets and the back sits in a rabbet.

I decided to run a series of dadoes in the sides, each 1/2" wide and on 2" centers. The undersized 1/2" plywood slides nicely in the dadoes. The drawers are as simple as can be. Basically, a shelf with four pieces attached to the top side - all butt joints. Because of the evenly spaced dadoes, I can move differently-sized drawers around as I please.

I haven't got the casters yet, but I'm leaning towards four swivels and skipping the lazy susan on top. The primary purose of the cart is to put stuff on while it is being machined. Ironically, in the making of this cart, one of the gables fell of my jointer bed and the corner got damaged. No longer!

I believe that the routers I have on the bottom should keep the cart from tipping. I never realized how heavy the routers are, or how heavy the cart itself would be, even when empty! I really wanted to install a vise or bench/wonder dogs on one of these carts, but I don't think they are stable enough to provide any benefit. I like Ralph's idea of a tray top, and I make make one by adding on extra-wide edge banding. That would also raise the height of the cart top.

Gary, I like your idea of organizing on-the-go projects. I usually have many on the go and I'm forever moving them out of the way.

Chris, I like the cart, looks very versatile, also like the draws that way. I kind of got the idea from the other posts, on the inside storage, (Wot, Ralph, and Don), seemed to me they were going along that line. I am also limited on space and am always moving things back and forth, I will have to study these closer and possibly build one my self. Again good job!. garyowen

Nice cart, Chris. But, I think your tires are flat. ;-)

"Nice cart, Chris. But, I

"Nice cart, Chris. But, I think your tires are flat. ;-)"

Ralph - the cart is more stable with flat tires.

Three Wheels

Hi Flair.

I thought I'd let you get all your carts built, then chime in.

Three wheels forever, what I say.

I have my planer, jointer, a small tablesaw, and a miter saw, all on carts with three wheels. I haven't had any problem at all with top-heaviness or instability (uh, of the carts, that is). Oh, and the bandsaw is on a three-wheeler too. That's a top-heavy item, but no problem. Actually, the band saw cart works the best of all.

If the cart started to tip, the front end is only an inch at most off the floor, so not much real room to tip. The third wheel is only for when moving the cart. After that, you kick the thing with your toe and the cart settles down on four points, same as locking it in postiton, but without having to go around to each wheel and fiddle at the levers with your toe. The rear wheels are fixed and on the floor at all times.

The reason I started in with three-wheel carts, and the reason I like them so much, is the steering. They steer like butter!

--jonnieboy

Oh yeah, lazy susans. I put my shop-vac in a sound insulated box and put that box on a lazy susan. Sounded like a good idea at the time, but it's a real pain, I'd never do that again. I have to undo that set-up. Some day.

--jonnieboy

Super Agility

Jonnie,

Your three wheeled concept is an interesting one. My Delta table saw has a three-wheeled mobile base with two straight wheels at the end and one swivel caster at midpoint. It works alright, but to get it positioned right, I have to roll it forwards and backwards a lot in my shop, like parallel parking in a parking spot that's really tight. Come to think of it, T-bar type mobility kits have two straight casters at one end of the tool and a mounting point/pivot for the T-bar and two more casters at the other end.

I'm really happy with the carts I built. I used four swivel wheels on each, all of which lock. They are 4" diameter. I ran 1/2" kerfs every 2" on the inside of the gables which allow me to put in drawers 1-7/16", 3-7/16", 5-7/16", etc. The 1/2" kerfs allow the undersized 1/2" plywood bottoms to slide in freely. The drawers feature simple construction - just a front and back with two sides brad nailed and glued to each other and to the bottom. I also added some steel channels to hold tape measures and marking tools. So while the top serves the primary purpose of material handling, the sides and inside of the cart are used for storage (router and router accessories on this cart).

Nice

Hey Chris,

The cart turned out great. I like the idea of material handling on top yet still having storage. Always need more storage.

Is that a paint finish?

What's the box on the side for?

--jonnieboy

You know, it just occurred to me what you did. It almost went right by me. I'm not saying you're thinking of it in this way, but the way you have the tools grouped on your cart like that sparked an idea. You sort of have a marking/measuring cart there.

I haven't built a tool cabinet yet, but I've been thinking in terms of marking/measuring tools, joinery tools, assembly tools, etc.; tools grouped together for each subsection of a project . But I was thinking of those groupings as being within a tool cabinet. How about an assembly cart, and a layout cart, a joinery tools cart? That would take way too much room. But two or three of those functions could be combined on one cart. Yeah... Then, you stay in the same place in the shop, especially in my small shop, but the tools come to you. The layout cart rolls out and the joinery cart rolls in.

That's an idea worth thinking more about. Chris, you're a genius.

--jonnieboy

I don't go to my tools - My tools come to me

Jonnie,

The carts are unfinished. They are made of poplar 3/4" plywood for the carcass with 1/2" pine ply for the back and drawers and shelves. The box hanging off the side is on a french cleat and stores the little plastic divider boxes (Plano-type) that I like to store hardware in.

I work in a divided shop, with a wall and sliding glass door between my benchroom and my machine room. The benchroom is heated, the machine room not heated. Previously, I've been storing as much as I can in the heated benchroom. But because I use my power tools in the other room, it means I had to bring them outside everytime and go back and forth to get the associated accessories (wrenches, blades, etc). Now I have all my routers on one cart along with their wrenches, bits, collets, and bushings. I can just roll the cart out the door and I am good to go.

Having a number of specialized carts might be a good idea - you can just bring out the one you need. Storing them may or may not be an issue. One solution would be to store them against a wall below a benchtop or wall-mounted cabinets. It would be not different than having floor-to-ceiling cabinets.

Router Cart! Come Hither!

Chris,

Yep, you got it. That's exactly the way I was thinking of it. I'll have to plot on how I could use that idea in my shop. I know I could do it with all the various wrench sets, pliers, channelocks, etc. Those things are never where I need them to be. Surprising how much I use them, being a woodshop.

Except, of course, I'll use THREE WHEELS!!

--jonnieboy

Chris,

I thought you wanted something for material handling not tool storage.

This is the type of simple yet functional cart we used in our production shop primarily used to transport cabinet parts from the cutting area to the assembly area. Just big enough not to tip easy. Long stock can stack horizontally across the top and small parts can stack inside or rectangular pieces can stack vertically like books.

We kept the tools at the individual work stations and didn't move them around too much.

Well, I guess I did say that I wanted a cart for material handling. What I really meant was that I wanted a mobile horizontal surface that I could put stuff on top of. The top of the first car provides space for material handling and the space below holds ballast.

Chris,

I wrote an article on this subject for FWW a couple of years back. You could probably find it in the archives if you're interested. My approach was to purchase a steel hydraulic lift cart, and I've never regretted the decision.

I bought mine for about a hundred bucks. It's a cheap Chinese import, but is perfectly adequate for my needs. Its top table measures about 18x24 inches (can't remember exactly right now, and I'm not in my shop), and I built an auxilliary wooden top larger than that.

The good thing about a hydraulic lift cart is that you use its hydraulic cylinder to jack the top up and down on a scissors mechanism. Mine goes (with auxilliary top attached) from about 18 inches high to about 37, in about 30 or so presses of my foot on the pedal. I can fine-tune its height to use as an outfeed table if I need it for that purpose, but I mostly have it around for tranporting parts from sliding miter saw to the tablesaw, for example. As the pile of parts goes down I can jack the cart up so I'm not stooping over to retrieve them..

It is also very handy to put an entire project on, say a table or desk, so you can rachet it up and down to work on the base or top without having to lift it onto anything. I also use it occasionally for finishing. Its swiveling casters allow me to rotate it around in order to move a piece into the best light.

In the end it was cheaper for me to buy this unit than build one (casters are pretty spendy), and I got a much more versatile cart than I would have otherwise. The up-and-down action is a very nice feature...

Zolton

Your idea sounds interesting. Where did you buy it?

Jerry

J Frost,

I got my utility cart at a local Chinese-import place - like a "local" Harbor Freight. I've also actually been to Harbor Freight and they have the carts there as well.

I got mine on sale for a hundred bucks, but I think they're in the $150-175 range at Harbor Freight, depending on the size you buy. Places like Grainger and Northern tool have them too, but they start out at about $300 there. Those might be better-made than the one I bought though...

Zolton

Thanks. I'll check Harbor Freight.

Lift Cart

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=94822

Zolton,

Does your cart look something like this?

Edit: The full link wouldn't print. Ask for Item #94822 at their site.

Links

You link actually worked for me. But sometimes it won't in other places. What you can do is feed the long link into a shortener like this one:

http://tinyurl.com/create.php?url=http%3A%2F%2Fwww.harborfreight.com%2Fcpi%2Fctaf%2Fdisplayitem.taf%3FItemnumber%3D94822

and you get this:

http://tinyurl.com/54e7cu

Jfrost,

Yep. Mine looks like that - only cheaper! There's no brake on mine. That is a brake on the handle, isn't it?

Brakes? Brakes? We don't need no stinkin' brakes!

But otherwise, yes, very similar..

Zolton

Lift Cart

I really like the lift capabilities of this cart however my other priorities trump the lift feature.

As soon as I finish my current project I will build an open front cart on 5" casters - 2 fixed, 2 swivel. As I have very limited shop space; floor AND walls are full, I have to store my oscillating spindle sander in the garage next to 2 Festool boxes: for a router and a circular saw.

I'm getting tired of lugging the sander into the shop (It's awkward and heavy.) and I'd like to save the floor space used by the two Festool boxes. (That's what trumps the lift feature. The commercial stand does not have storage room underneath.) I will build it to a height that matches the lower of my jointer, and table saw heights. A simple "filler board" on top will convert it into an outfeed table for either.

Frosty

How about doing a flip-top design, Frosty? There have been a couple of past articles in FWW that featured a cart where a machine, such as a spindle sander or lunch-box planer was mounted to a frame inside the cart exterior panels, such that it could be flipped over, providing a flat surface, and then rolled under a bench or table saw extension. I tried searching for the article, but couldn't immediately find it.

I remember the article. I'll try to find it. But, I don't want to lose the storage space for the 2 Festool boxes.

Thanks for the suggestion.

Frosty

Jim,

I now have three drawers in my shop!

I currently have a metal cart that was probably used as a stand for a typewriter(remember those?) with swivel casters; non-locking. It works well as an auxilliary cart for parts, finishing, and storage of junk. Shopnotes magazine(hope it is OK to say another magazine title here) has in their current issue a great all-wood cart with locking casters & drawers made entirely of construction lumber. Looks great, with basic joinery, and is on my short list of shop projects. Unlike the plans they show, I plan to add a small vise to mine.

Good luck and watch those fingers.

See the most suitable artciles

If you're to cognizant of (advice: you are since you're reading this), your animation is, from just now on, event on overtime. You comprise been giving another endeavour, another bite at the apple. My question to you is: are you active to in the end start living your life? Are you booming to produce the conquer out of the closet of your borrowed time? Would you send yourself franchise to live more, to do more, and to be more?

I hope [url=http://www.czyste-wnetrze.pl]sprzątanie konstancin[/url]

[url=http://www.skup-aut-wroclaw.org]skup aut wrocław[/url] you don't take in yourself in the time today as a "witness". I hope that your explanation is not: "since we are all common to go to meet one's maker harmonious lifetime, what's the use".

You [url=http://deltaforce.pl]naprawa wideodomofonów kraków[/url] be struck by been giving indulgence to spend life to the fullest, to go after your dreams starting today. No more Shakespearean aspect of to be or not to be dead. Physical, burning, and loaded some more! That should be your only purpose. Impel it your duty to be the largest mortal being you can peradventure be, the tucker Mom/Dad, the most festivity being, the most compassionate ally, the most optimistic yourselves you can be. Cut out a betoken to yourself to mother's ruin every tear of survival insatiable well starting today.

It's been said that [url=http://www.ceresdevelopment.pl]mieszkania legionowo[/url] a dead myself is someone without a dream. Be a dreamer. Define what you want today. That's the only plead with why you are inheriting the Delivery Mayan-Calendar's world on today's date. You have my leniency to start dreaming today. And since you're accepted to start dreaming, you ascendancy as extravagantly day-dream BIG. Shoot quest of the stars because if you miss, you will find the moon. In my opinion, that's very much worthwhile. Whatever you do, from today on, don't give permission your dreams die. Subsistence them bustling by keeping your hankering alive.

Since the ambivalent

[url=http://www.hest.pl]salon kosmetyczny warszawa[/url] trick will be the unvarying instead of all of us (no united intention climb escape of it among the living, guaranteed!), you do not need to actual a totally unpolluted ‚lan vital during not irresistible any designed risks, or by not going after what you be sure into down that you absolutely want. If your day-dream is to be the world's worst ballet dancer, balladeer, carpenter, by the tag of God, lead with a view it! If you want, not sole to reach the sky, but to zip pass it, go recompense it!

See the most suitable artciles

If you're to cognizant of (advice: you are since you're reading this), your animation is, from just now on, event on overtime. You comprise been giving another endeavour, another bite at the apple. My question to you is: are you active to in the end start living your life? Are you booming to produce the conquer out of the closet of your borrowed time? Would you send yourself franchise to live more, to do more, and to be more?

I hope [url=http://www.czyste-wnetrze.pl]sprzątanie konstancin[/url]

[url=http://www.skup-aut-wroclaw.org]skup aut wrocław[/url] you don't take in yourself in the time today as a "witness". I hope that your explanation is not: "since we are all common to go to meet one's maker harmonious lifetime, what's the use".

You [url=http://deltaforce.pl]naprawa wideodomofonów kraków[/url] be struck by been giving indulgence to spend life to the fullest, to go after your dreams starting today. No more Shakespearean aspect of to be or not to be dead. Physical, burning, and loaded some more! That should be your only purpose. Impel it your duty to be the largest mortal being you can peradventure be, the tucker Mom/Dad, the most festivity being, the most compassionate ally, the most optimistic yourselves you can be. Cut out a betoken to yourself to mother's ruin every tear of survival insatiable well starting today.

It's been said that [url=http://www.ceresdevelopment.pl]mieszkania legionowo[/url] a dead myself is someone without a dream. Be a dreamer. Define what you want today. That's the only plead with why you are inheriting the Delivery Mayan-Calendar's world on today's date. You have my leniency to start dreaming today. And since you're accepted to start dreaming, you ascendancy as extravagantly day-dream BIG. Shoot quest of the stars because if you miss, you will find the moon. In my opinion, that's very much worthwhile. Whatever you do, from today on, don't give permission your dreams die. Subsistence them bustling by keeping your hankering alive.

Since the ambivalent

[url=http://www.hest.pl]salon kosmetyczny warszawa[/url] trick will be the unvarying instead of all of us (no united intention climb escape of it among the living, guaranteed!), you do not need to actual a totally unpolluted ‚lan vital during not irresistible any designed risks, or by not going after what you be sure into down that you absolutely want. If your day-dream is to be the world's worst ballet dancer, balladeer, carpenter, by the tag of God, lead with a view it! If you want, not sole to reach the sky, but to zip pass it, go recompense it!

This forum post is now archived. Commenting has been disabled