I’m looking to create a very thin slot 1/16″ or less for nearly the complete length of a 6′ 1×2. Slot cutting router bits seem to all be too large. Any ideas how to accomplish this with a router?

Discussion Forum

Get It All!

UNLIMITED Membership is like taking a master class in woodworking for less than $10 a month.

Start Your Free TrialCategories

Discussion Forum

Digital Plans Library

Member exclusive! – Plans for everyone – from beginners to experts – right at your fingertips.

Highlights

-

Shape Your Skills

when you sign up for our emails

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. -

Shop Talk Live Podcast

Shop Talk Live Podcast -

Our favorite articles and videos

Our favorite articles and videos -

E-Learning Courses from Fine Woodworking

-

-

Replies

There are slotting saws that can chuck in a drill press. Basically a roundsawblade on an arbor. They come in various thicknesses.

“[Deleted]”

Dremel makes very thin saw blades like that in various diameters. A dremel router would be ideal but a drill press could work once you figure out the set up. It doesn't look like there is much space between the bottom of your slot and the bottom of the dado and the fastener on the dremel saw blade to the shaft is quite narrow and would likely clear. That might not be so even if you could find a slot cutter that narrow for a router. I don't think I would try to do both sides at once ( like a 1 1/4" or something diameter). I have a set of those dremel saw blades and I think that the smallest one I have is only 1/2"in diameter so might permit slightly less than a 1/4" slot and maybe not even 1/16th thick. I ran one of those saw blades across a knuckle one time, I could measure the scar if you like.

Thanks for your input! I am looking at the small Dremel (and Dremel-like) tools. This scale of cut is more in line with that type of tool I feel like. And thanks for the knuckle warning! Ouch.

The blade is 1/8 brass stock, so I'd be looking to cut a slightly.involve attaching either brass strip until the wood is notched.

DGCustomerFirst

The easy way to do this is to cheat.

Make your original stock somewhat thicker than you need.

Cut a slice off the top which is somewhat deeper than the distance above your narrow slot. Joint the cut sides.

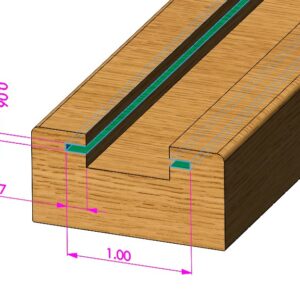

Cut a dado 1 inch wide and 1mm or 0.06 inch deep in your stock.

Glue your 'top' back on. Careful not to get squeezeout.

Thickness until distance from top to narrow groove is perfect.

Cut dado in middle of slot to full depth.

This is the best way I can think of for you to achieve your 'engineering' tolerances.

If you intend to embed something in it, it would be easiest if you do the embedding before you stick the top on - wood is difficult to get that precise and if there is no tolerance in your design then it will be almost impossible to slide something down the slot created.

Really interesting idea! I am concerned that my rudimentary woodworking skills (not to mention lack of a proper shop) will leave me with a sloppy end result though. I do intend to slide a piece of thin plastic down the groove, so I am incorporating some clearance/tolerance to the design. Fingers crossed I can get it to work.

If you want to try it unplugged it could be done with a scratch stock with less chance of mayhem.

That's an interesting idea - just did a little research into what a scratch stock is. I'm very new to woodworking and hadn't heard of it before. For my purposes, it appears to be a bit too labor intensive, but I'll keep it as a backup plan!

They will also modify them for you if you ask. You would also need to come up with a stub spindle due to the shallow groove. They might be able to provide that as well.

https://www.whitesiderouterbits.com/collections/slotting-cutters/products/6700a

Thanks. The problem I've seen with the slot cutters is that the overall diameter of the tool is too large. It has to be around an inch (max 1 1/4) and even at that diameter, it would force me to cut both sides at the same time which seems a bit sketchy to me. I don't think they show the overall diameter of this tool on that site.

“[Deleted]”

I appreciate all of the quick feedback...It's given me some more ideas on how to accomplish this and will keep you posted of my success (or lack thereof)!

I ended up getting a really small circular saw blade (meant for a Dremel I suppose) and using that in the router to cut the slot. It works, but it burns the wood quite a bit, understandably.

Thanks for the follow-through.

The router is just too fast for that blade - even at lowest speed it will be about 5 times faster than the blade is intended to run, hence the burning.

Glad it worked tho!

That looks kinda sketchy-scary. Would you do it again?

This forum post is now archived. Commenting has been disabled