Hi,

I build tables and islands commercially but newer to the business. People seem to like my style. I didn’t even know I had one! I’m doing a commissioned job which is a 4’ long table, 24” wide and 36” tall with a waterfall edge at one end. This will be 8/4 Bubinga. I’m planning to edge join the boards using Dominos and glue for the entire length before making the cuts. Open question is whether to use epoxy or wood glue on the corner. To provide the structural support I’m using a 5/4 shelf made from Ash that connects directly into the Bubinga leg and runs out to the other end. At the other end, are two large ash legs which will go through the ash shelf and naturally seat onto the leg just using the width of the leg/tenon and come to the surface of the table top. The goal is not to use any screws or steel brackets

I would appreciate greatly any advice on my design and concerns it raises on any and all fronts. Also on the cut, and finally any insights on finishing Bubinga. I am trying to avoid any substructure other than possible joining the shelf and top in the center once or twice. It should be a pretty cool look. Not planning a leg stretcher. I’d truly appreciate insight and wisdom my practical experience can’t provide.

Replies

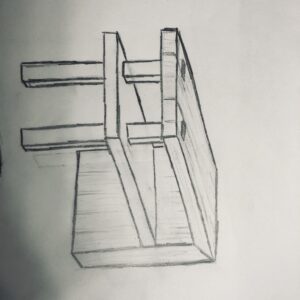

Oddly enough I have a miniature of your leg arrangement on my bench right now. I made the "legs" overlong and removed material to create a double-long mid-leg tenon that I cut in half, and then half-lapped. The effect is the board going through the "shelf". (photos below)

For the waterfall I'd suggest a full-width spline for alignment and a handful of dominos for strength. Make sure the dry fit is PERFECT and figure out clamping before you begin. If all of the parts are fitted you'll be able to use the legs and shelf to help with the clamps. Slow set epoxy would be my choice.

Thank you for all the great advice. The goal is to have a through tenon for the legs. I didn’t quite follow how you accomplished it, but will research further. Thank you!

Cut the tenon cheeks & shoulders with a dado stack in the middle of the leg, making it twice as long as the shelf is thick, then cut it in half and remove the opposing waste-halves to form the internal half-lap. See photo below.

This is brilliant!

Thanks JV, appreciate the good vibes!

That's elegant!

Thank you for all the great advice. The goal is to have a through tenon for the legs, so the shelf literally sits on the leg. I didn’t quite follow how you accomplished it, but will research further. Thank you!

I recently built an oak desk with 2" water fall edges all around. I generally agree with MJ. However, I think that using both a spline and dominoes is not necessary. It would just add complexity to the join-up. I would add that, if you use a spline, make sure that it is cut cross-grain so that the grain of the spline runs the same direction as the table. I agree with using epoxy. It will add strength to your end grain glue-up and give you lots of working time.

Cool design. For the legs I would consider through tenon joinery with the shoulders supporting the weight on the shelf and top. That would result in the ‘post’ between the shelf and top being a smaller dimension, but visually, it might work. I would also kerf and wedge the through tenon on the top.

There's a good article on this site for making L-tenons for large miter joints. I'd look into that for the waterfall end.

Check out Classic woodworking Season 1 episode 6 to see how Tom McLaughlin handles that mitre joint.

To glue the miter, definitely use long set epoxy. Butter the two miter surfaces, wait about 5 minutes for the epoxy to soak into the end grain, then re-apply more epoxy. This allows the epoxy to fill the end grain before your clamp pressure reduces the amount of glue available to do that.

The best way to clamp the miter is to make two identical cauls. Use a strip of plywood or a board 24" long, and glue to it another 24" long piece which has one edge cut at a 45º angle. Arrange the geometry so that you can clamp the cauls to each piece so that a line drawn thru the middle of the miter joint perpendicular to the joint surface goes thru the middles of the two 45º surfaces on the cauls. That way, when you clamp between the cauls, you are applying pressure to the miter joint without trying to slip the pieces one way or the other. You can glue sandpaper to the bottoms of the cauls if you wish; a dry clamp trial will determine if that is necessary. You WILL need cauls and clamps to get a tight joint with epoxy, as it has a thicker consistency than yellow glue. (If you glue sandpaper to the cauls, don't use contact cement, as it will allow slippage.)

I definitely recommend either a spline (with grain oriented the same as two pieces, as noted above) or biscuits.

For the long joint to make the top/waterfall blank, I would use biscuits or a spline, or at most very short Dominoes, as they are cross grain to the top. Whatever you use should be primarily for alignment, as your glue joint should be good enough to stand on its own structurally.

If you are going to round over the outside edge of the miter joint, one trick for cutting the miters is to cut the two pieces to length, making sure they are very square, then set your tablesaw blade to 45º, trap the top of the blade in a sacrificial board clamped to the fence, and put the fence so that a very small amount of the square end is left at the top, riding on the fence board. This way, you can even run the board thru again if the first cut wasn't done perfectly. If the square cut was perfect, the miter will be as well.

To be honest, I understand the attraction of the clean design, but the leg end of the top may need more structure to hold the bubinga flat as the seasons alternate. If you do put stretchers between the legs under the top and shelf, you will need to allow for seasonal movement in the width between the legs. Best way I see is to house the ends of the stretchers in mortises in the legs, and leave the stretchers a bit short, so if the top shrinks, there is room for the stretchers to go deeper into the legs. Then you would need to attach the stretchers to the underside of the top and shelf with the dreaded screws (and slotted holes for all except the center hole.)

All of what @ JHarveyB says will work. The only thing not correct is about the dominos... the grain of a domino runs along its length, which would match the grain orientation of the top. Biscuits are about 50/50 as they are made with diagonal grain.

Use the thickest and longest dominos you can, starting them low to the inside corner of the miter. They add more strength than biscuits... definitely make test cuts on samples of the same thickness to make sure you don't blow through the top.

I appreciate the thoughtful feedback from everyone. In today’s world, you just don’t see as much collaboration or peer input it seems. Namely, people who share a common passion, taking the time to help a stranger succeed. It’s a real credit to this community.

I was hesitant to post on here, and while the input has been great, the best take away is having learned what a great resource there is here.

Check out Tom McLaughlin's waterfall edge coffee table on classic woodworking. It is a piece of art.

Spamarama

This forum post is now archived. Commenting has been disabled